Friction-resistant brake disc and preparation method thereof

A brake disc, friction-resistant technology, applied in the direction of brake disc, brake type, brake components, etc., can solve the problems of brake pad wear, long continuous braking time, large coating roughness, etc., to achieve extended life, The effect of reducing brake wear and increasing braking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

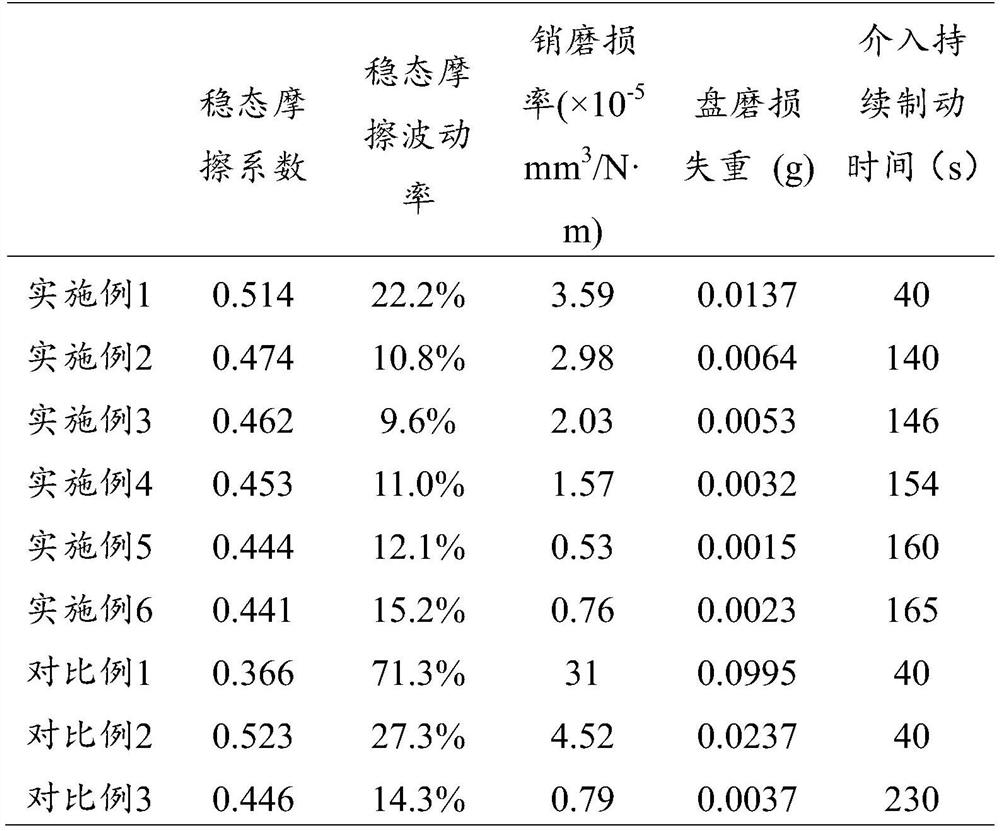

Embodiment 1

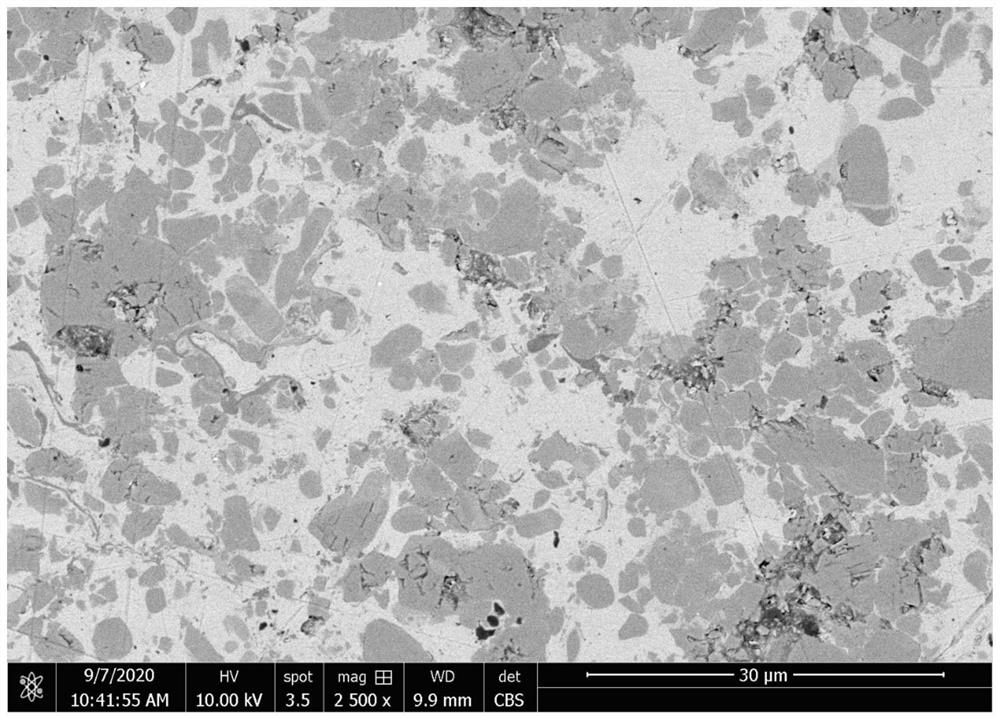

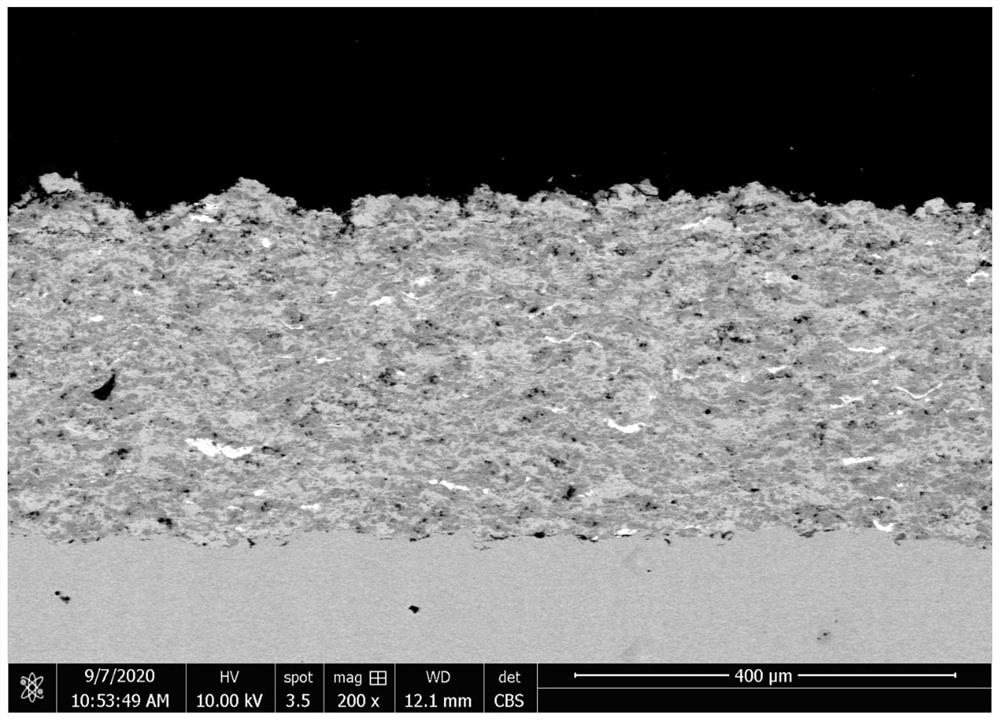

[0032] As a kind of anti-friction brake disc according to the embodiment of the present invention, the anti-friction brake disc includes a brake disc substrate and a coating on the surface of the brake disc substrate; the material of the coating is chromium carbide-nickel-chromium cermet , the chromium carbide-nickel-chromium cermet is Cr 3 C 2 -25NiCr; the surface roughness of the coating is 1.0 μm, the material of the brake disc base is 30CrSiMoVA, and the thickness of the coating is 300 μm.

[0033] The preparation method of the friction-resistant brake disc of this embodiment comprises the following steps:

[0034] (1) Cast the brake disc base body, degrease and clean the two friction surfaces of the brake disc base body, use 24# zirconium corundum sand to roughen the surface of the friction surface under a pressure of 0.3MPa;

[0035] (2) forming a coating by supersonic thermal spraying in powder form on the surface of the brake disc substrate treated in step (1);

[0...

Embodiment 2

[0038] As a friction-resistant brake disc according to an embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is that the surface roughness of the coating is 1.2 μm.

[0039] The only difference between the preparation method of the anti-friction brake disc of this embodiment and that of Embodiment 1 is that step (4) is also included, and the coating surface treated in step (3) is subjected to sandblasting treatment, the sandblasting particles are aluminum oxide, and the The sand pressure was 0.15 MPa, so that the surface roughness of the coating was 1.2 μm.

Embodiment 3

[0041] As a friction-resistant brake disc according to an embodiment of the present invention, the only difference between this embodiment and Embodiment 2 is that the surface roughness of the coating is 1.5 μm.

[0042] The only difference between the preparation method of the anti-friction brake disc of this embodiment and that of Example 2 is that step (4) is also included, and the coating surface treated in step (3) is subjected to sandblasting treatment, the sandblasting particles are alumina, and The sand pressure is 0.15MPa-0.35MPa, so that the surface roughness of the coating is 1.5μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com