A preparation method of high-strength and stress-corrosion-resistant aluminum alloy profiles

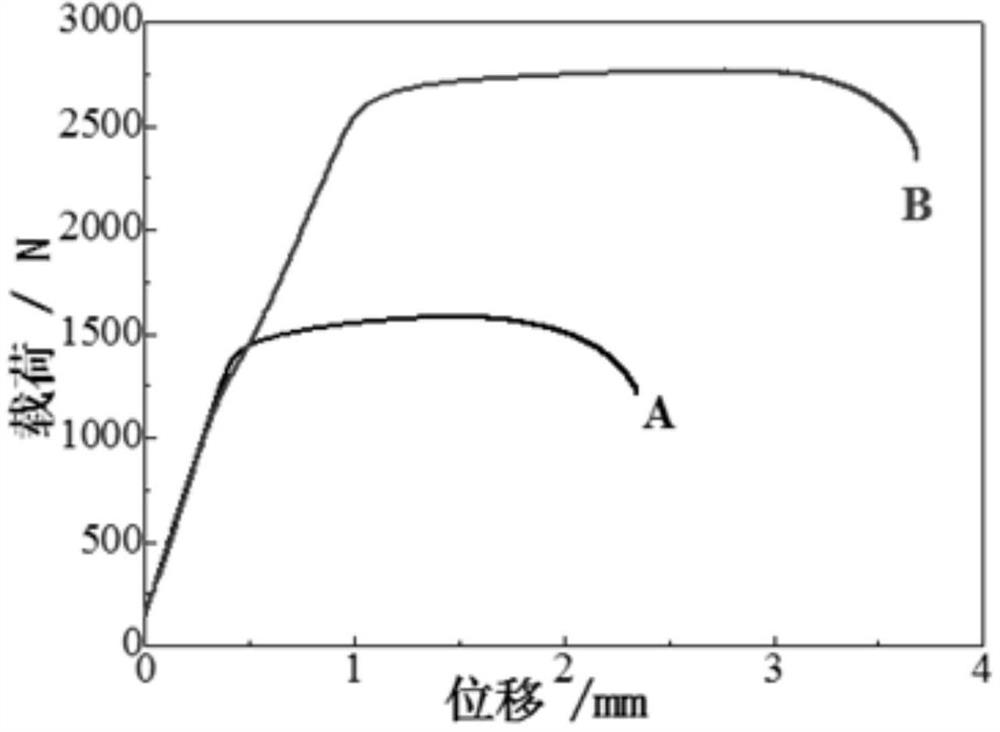

A technology for stress corrosion resistance and aluminum alloy profiles, applied in the field of metal material processing, can solve the problems of low strength and poor intergranular corrosion resistance of aluminum alloys, and achieve improved structure, improved strength of aging alloys, and microalloying effects. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

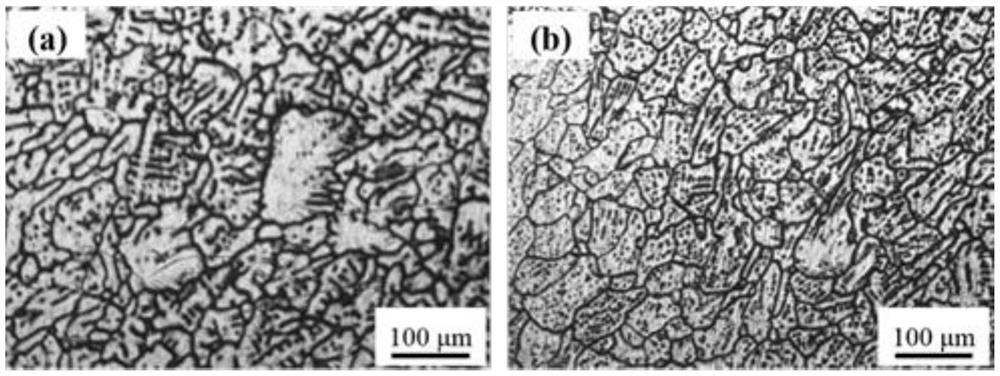

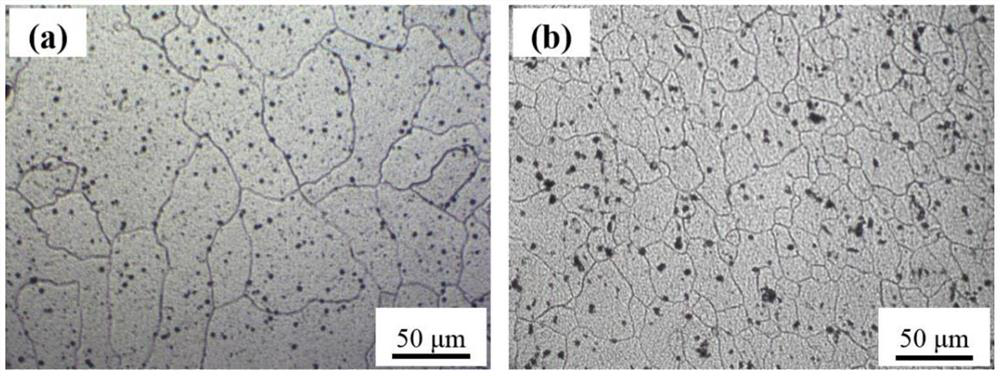

Image

Examples

Embodiment 1

[0030] A method for preparing a high-strength stress-corrosion-resistant aluminum alloy profile, comprising the steps of:

[0031] (1) Ingredients and smelting: select raw materials to remelt refined aluminum ingots, pure magnesium ingots, cathode copper, zinc ingots, aluminum-silicon master alloys, aluminum-manganese master alloys, aluminum-titanium master alloys, Al-10% Y alloys, Al-5 %Sc alloy and Al-10%Sr alloy, according to the weight percentage of the following elements Mg: 0.9% ~ 1.05%, Si: 0.45% ~ 0.65%, Cu: 0.15% ~ 0.30%, Y: 0.10% ~ 0.20%, Sc : 0.05%~0.15%, Sr: 0.09%~0.15%, Cr≤0.10%, Zn≤0.10%, Fe≤0.12%, Mn≤0.10%, Ti≤0.10%, total amount of impurity elements≤0.15%, balance For Al, weigh raw materials for batching;

[0032] Add the above raw materials: remelted refined aluminum ingots, copper cathodes, zinc ingots, aluminum-silicon master alloys, aluminum-manganese master alloys, aluminum-titanium master alloys, and aluminum-titanium-boron grain refiners into a dry inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com