Light and heat storage type composite phase change material for energy storage and preparation method of light and heat storage type composite phase change material

A composite phase change material and energy storage technology, which is applied in the field of light storage and heat storage type composite phase change materials and their preparation, and can solve the problems of limiting the application of solid-liquid phase change materials, single energy storage and release form, and poor shape stability. , to achieve the effect of excellent light storage, strong operability and low leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

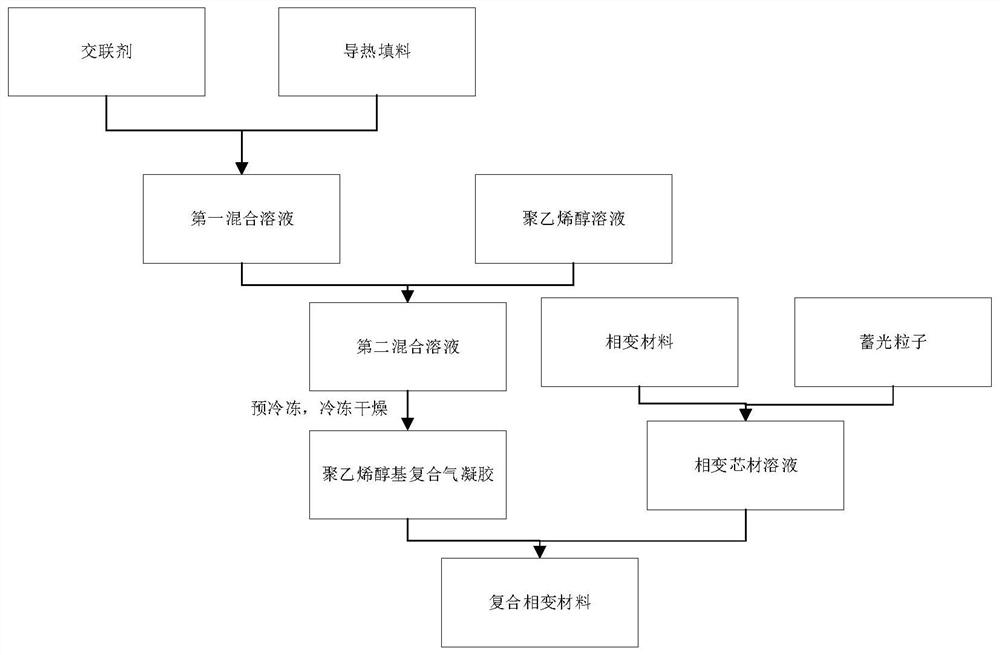

[0034] Please refer to figure 1 , an embodiment of the present invention provides a method for preparing a light-storage and heat-storage composite phase change material for energy storage, comprising the following steps:

[0035] Step S1, adding polyvinyl alcohol into deionized water, stirring and dissolving at 85-100° C. for 1.5-3 hours to obtain a polyvinyl alcohol solution with a concentration of 10-30 mg / mL;

[0036] Step S2, mixing the crosslinking agent and the thermally conductive filler, and ultrasonically agitating at 20-40° C. for 10-30 minutes to obtain the first mixed solution; wherein, the mass ratio of thermally conductive filler: crosslinking agent: polyvinyl alcohol is: (0-10 ): 1: (3-8); the crosslinking agent is selected from paraformaldehyde, glutaraldehyde, boric acid, borate, maleic anhydride, phthaloyl chloride, phthalic anhydride, succinic anhydride, phthalic acid, Any one of epichlorohydrin or copper hydroxide, the concentration of the crosslinking ag...

Embodiment 1

[0044] Embodiment 1 of the present invention provides a method for preparing a light-storage and heat-storage composite phase change material for energy storage, comprising the following steps:

[0045] Step S1, adding 0.6 g of polyvinyl alcohol into 30 mL of deionized water, stirring and dissolving at 95° C. for 2 hours until the polyvinyl alcohol is completely dissolved to obtain a polyvinyl alcohol solution;

[0046] Step S2, mixing and dissolving 0.12 g of boric acid and 0.3 g of boron nitride (BN) into 30 mL of deionized water, and ultrasonically stirring at 30° C. for 15 min to obtain a mixed solution of boric acid and boron nitride;

[0047] Step S3, adding the mixed solution prepared in S2 to the polyvinyl alcohol solution prepared in S1, stirring continuously at 95°C for 20 minutes until the solution is evenly dispersed;

[0048] Step S4, pre-freezing the mixed solution prepared in S3 for 12 hours in a refrigerator, and then freeze-drying for 72 hours at -52°C and a v...

Embodiment 2

[0064] Embodiment 2 of the present invention provides a method for preparing a light-storage and heat-storage composite phase change material for energy storage, comprising the following steps:

[0065] Step S1, adding 0.6 g of polyvinyl alcohol into 30 mL of deionized water, stirring and dissolving at 95° C. for 2 hours until the polyvinyl alcohol is completely dissolved to obtain a polyvinyl alcohol solution;

[0066] Step S2, mixing and dissolving 0.15 g of boric acid and 0.15 g of silicon carbide into 30 mL of deionized water, and ultrasonically stirring at 25° C. for 30 min to obtain a mixed solution of boric acid and silicon carbide;

[0067] Step S3, mixing the mixed solution prepared in S2 with the polyvinyl alcohol solution prepared in S1, and stirring continuously at 85° C. for 30 minutes until the solution is uniformly dispersed;

[0068] Step S4, pre-freezing the mixed solution prepared in S3 in liquid nitrogen for 30 minutes, and then freeze-drying for 48 hours un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com