Die-casting release agent for aluminum alloy structural parts

A technology of release agent and structural parts, which is applied in the direction of casting molds, casting mold components, casting molding equipment, etc., and can solve the problems of increasing the difficulty of wastewater treatment, difficult separation of organic components and water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

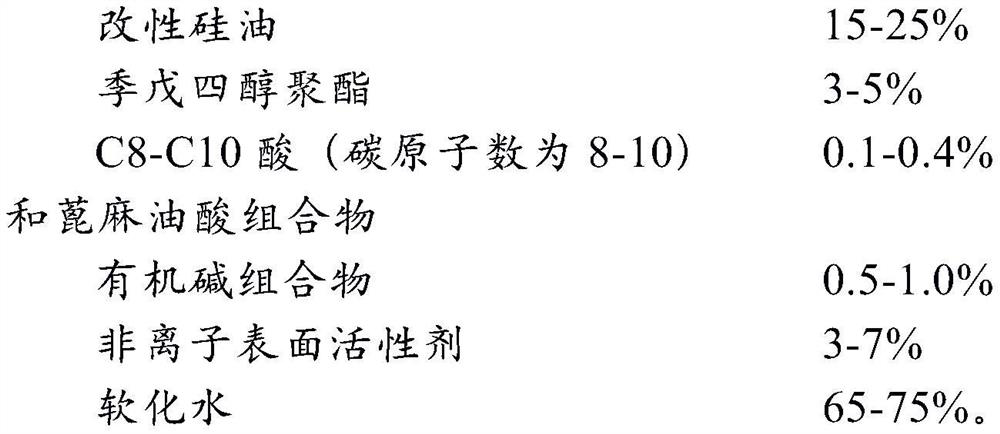

Embodiment 1

[0032]

[0033] The modified silicone oil is a modified long-chain alkyl aryl silicone oil.

[0034] The pentaerythritol polyester is prepared by reacting and polymerizing pentaerythritol and C10-C12 saturated dibasic acid, and then esterifying with monoacid. The ratio of pentaerythritol to C10-C12 saturated dibasic acid is 1.8:1. C10-C12 saturated dibasic acid: 50% sebacic acid, 42% dodecanedioic acid, 8% 3-ethyl suberic acid. Monoacids used for esterification: 31% octanoic acid, 58% capric acid, 3% dodecanoic acid, 7% 4,4-diethylhexanoic acid, 6,6-diethyloctanoic acid, 1% of which .

[0035] The C8-C10 acid and ricinoleic acid composition, wherein caprylic acid 38%, neodecanoic acid 21%, isooctanoic acid 12%, ricinoleic acid 29%

[0036] The organic alkali composition comprises: monoethanolamine is 22% by weight, triethanolamine is 48%; N-hydroxyethyloctylamide is 30%.

[0037] The nonionic surfactant: C13-C15 fatty alcohol polyoxyethylene ether EO13 accounts for 30%,...

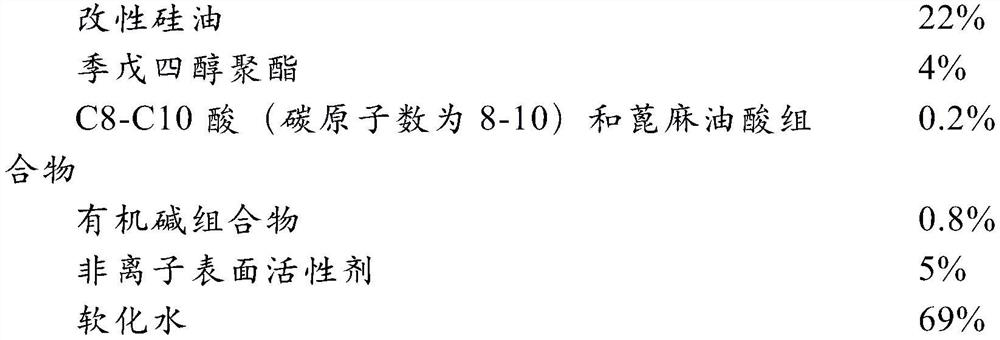

Embodiment 2

[0040]

[0041] The modified silicone oil is a modified long-chain alkyl aryl silicone oil.

[0042] The pentaerythritol polyester is prepared by reacting and polymerizing pentaerythritol and C10-C12 saturated dibasic acid, and then esterifying with monoacid. The ratio of pentaerythritol to C10-C12 saturated dibasic acid is 1.8:1. C10-C12 saturated dibasic acids: 61% sebacic acid, 30% dodecanedioic acid, 9% 3-ethyl suberic acid. Monoacids used for esterification: 66% octanoic acid, 24% capric acid, 3% dodecanoic acid, 6% 4,4-diethylhexanoic acid, 6,6-diethyloctanoic acid, 1% of which .

[0043] The C8-C10 acid and ricinoleic acid composition, wherein caprylic acid 20%, neodecanoic acid 29%, isooctanoic acid 20%, ricinoleic acid 31%

[0044] The organic base composition comprises: monoethanolamine is 19% by weight, triethanolamine is 51%; N-hydroxyethyloctylamide is 30%.

[0045] The nonionic surfactant: C13-C15 fatty alcohol polyoxyethylene ether EO13 accounts for 28%, ...

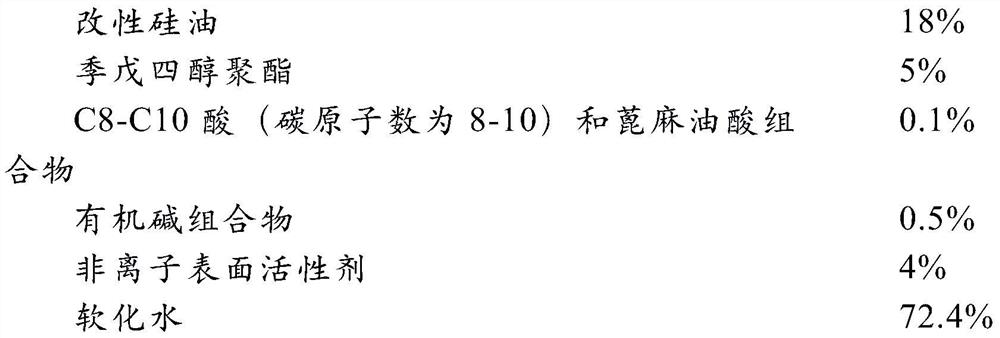

Embodiment 3

[0048]

[0049] The modified silicone oil is a modified long-chain alkyl aryl silicone oil.

[0050] The pentaerythritol polyester is prepared by reacting and polymerizing pentaerythritol and C10-C12 saturated dibasic acid, and then esterifying with monoacid. The ratio of pentaerythritol to C10-C12 saturated dibasic acid is 1.8:1. C10-C12 saturated dibasic acid: 50% sebacic acid, 42% dodecanedioic acid, 8% 3-ethyl suberic acid. Monoacids used for esterification: 31% octanoic acid, 58% capric acid, 3% dodecanoic acid, 7% 4,4-diethylhexanoic acid, 6,6-diethyloctanoic acid, 1% of which .

[0051] The C8-C10 acid and ricinoleic acid composition, wherein caprylic acid 38%, neodecanoic acid 21%, isooctanoic acid 12%, ricinoleic acid 29%

[0052] The organic alkali composition comprises: monoethanolamine is 22% by weight, triethanolamine is 48%; N-hydroxyethyloctylamide is 30%.

[0053] The nonionic surfactant: C13-C15 fatty alcohol polyoxyethylene ether EO13 accounts for 30%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com