Wafer cleaning method

A wafer, spray cleaning technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of higher efficiency than manual, leaving traces, drug printing defects, etc., to increase the variety of wafers and ensure stability performance, and the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

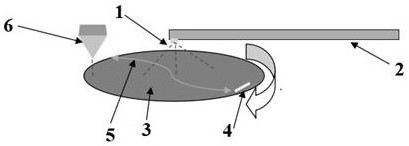

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

[0025] The existing wafer cleaning method is usually to spray the cleaning solution on the wafer surface at the center of the wafer, and use the centrifugal force generated by the rotation of the wafer to throw the cleaning solution to the edge to clean the surface evenly. However, when there is unevenness on the wafer surface, or laser marking is required on the main surface of the wafer for some purposes, when performing conventional single-wafer cleaning, the corrosive liquid will leave traces after flowing through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com