An all-in-one machine for primary twisting, plying, and multiple twisting for ceramic fibers

A technology of ceramic fiber and integrated machine, which is applied in the direction of textiles, papermaking, yarn, etc., can solve the problems of twisting defect cohesion, low elongation at break, high speed, etc., and achieve the effect of reducing wear and improving beam strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

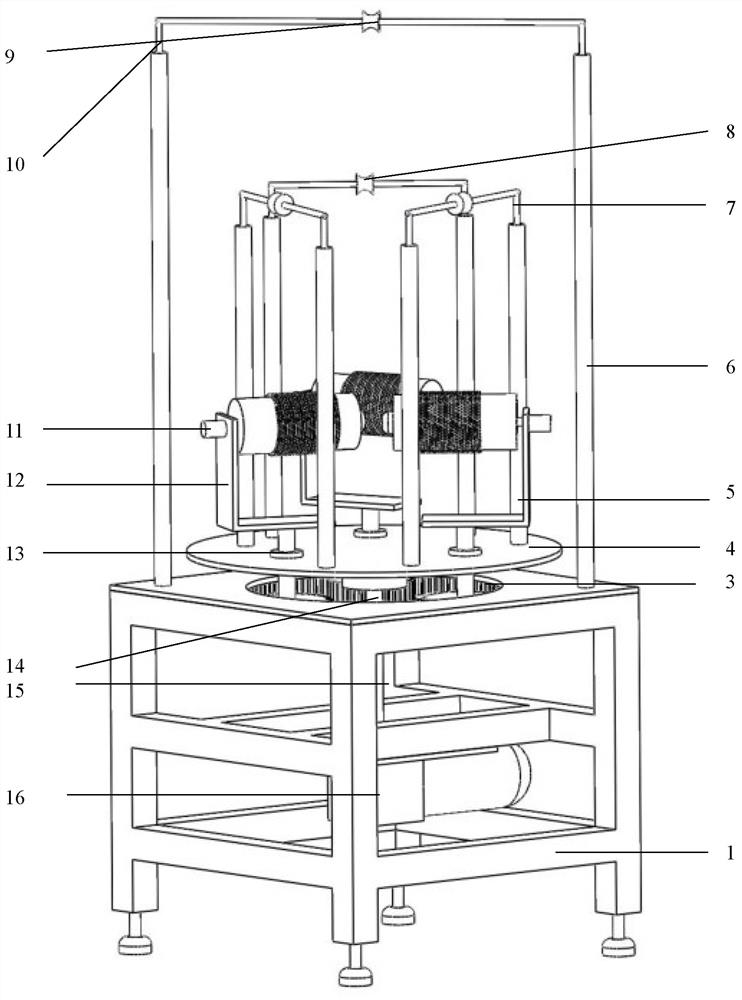

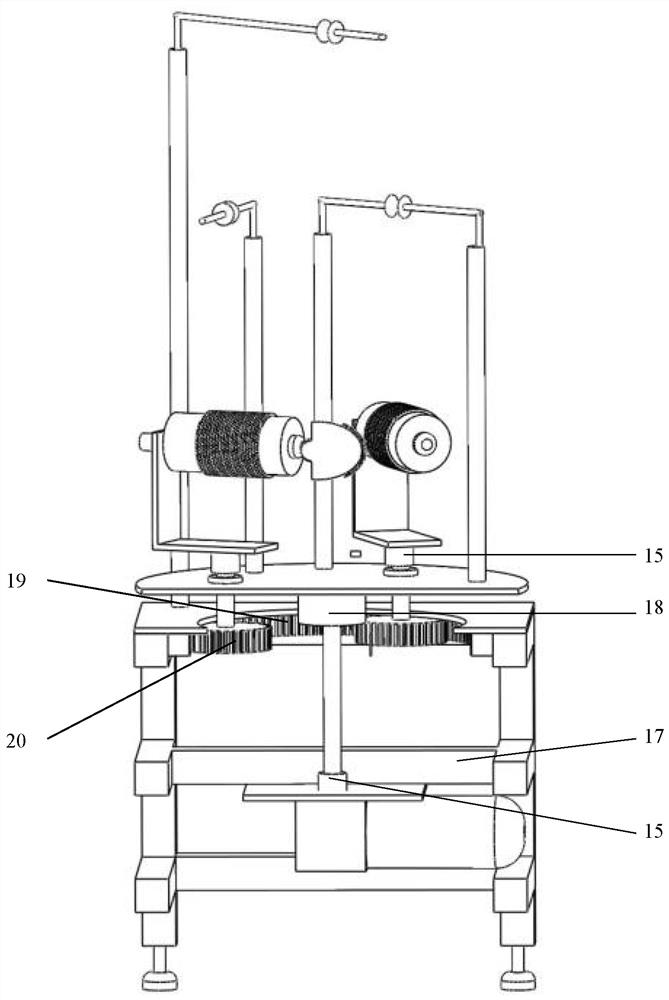

[0018] The present invention will be further described below with reference to the accompanying drawings and the following embodiments. It should be understood that the accompanying drawings and the following embodiments are only used to illustrate the present invention, but not to limit the present invention.

[0019] Aiming at the shortcomings of the existing plying and twisting equipment, which is carried out in steps, long in process and great wear on ceramic fibers, an integrated primary twisting, plying and re-twisting machine for ceramic fibers is provided. The integrated device includes a main body bracket, a planetary wheel mounted on the main body bracket, and a sun disk. The wire unwinding machine is coaxial with the planet wheel and fixed on the sun disk. The first godet wheel corresponding to the wire pay-off machine is arranged above each wire pay-off machine. The second godet is arranged above the plurality of first godets. The ceramic fibers on each pay-off m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com