Graphite thermal-field single crystal growth device for preparing silicon carbide crystals

A growth device, silicon carbide technology, applied in single crystal growth, single crystal growth, crystal growth, etc., can solve problems such as large temperature gradients, achieve the effects of reducing defects, ensuring quality, and reducing radial temperature gradients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

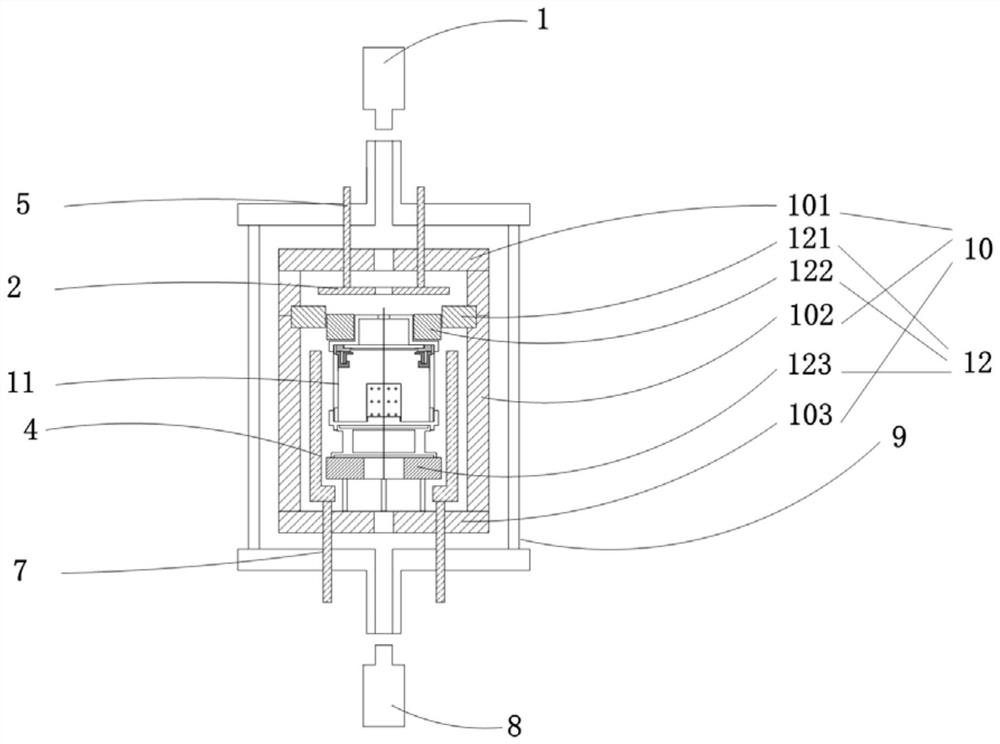

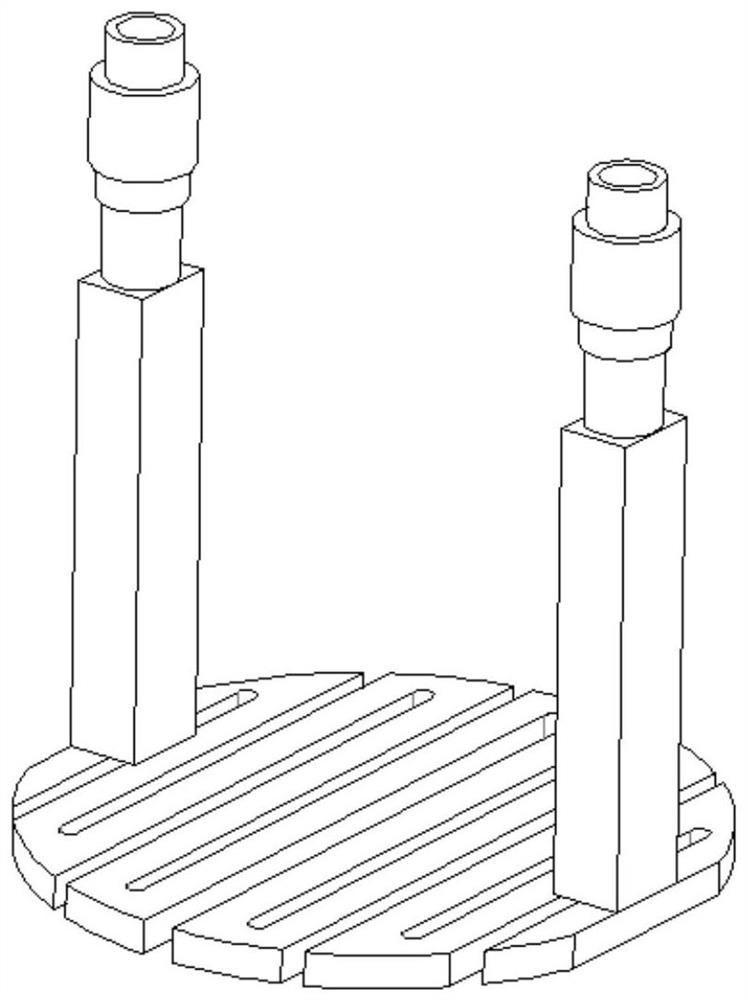

[0027] like figure 1 As shown, this embodiment provides a graphite thermal field single crystal growth device for preparing silicon carbide crystals, including a sealed cavity 9, a heating structure, a heat preservation structure 10, a temperature adjustment structure 12, a crucible 11 and a temperature measuring mechanism; The heat preservation structure 10 is arranged in the sealed cavity 9; the temperature adjustment structure 12 shown is arranged in the heat preservation structure 10, the heating structure is arranged in the heat preservation structure 10, and the temperature measuring mechanism is arranged in the sealed cavity 9 Above; the crucible 11 is set in the heat preservation structure 10 , and the seed crystal holder 112 is set in the crucible 11 .

[0028] In this specific embodiment, the sealed cavity 9 includes a cavity, an upper flange and a lower flange, the upper flange is arranged on the top of the cavity, and the lower flange is arranged on the bottom of t...

Embodiment 2

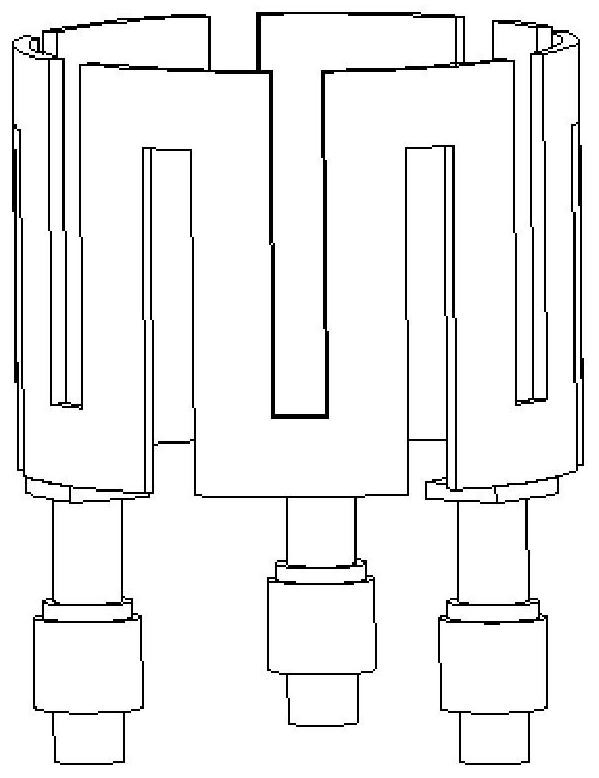

[0038] This embodiment is an improved embodiment based on the first embodiment. It is mainly for other schemes given for the arrangement of electrodes, such as Figure 5 As shown, the arrangement of electrodes can be adjusted on the lower electrode 7 of the matching electrode of the lower main heating resistor 4. The lower electrode 7 can be arranged in such a way that the electrode passes through the cavity and is parallel to the lower flange, and the electrode and the cavity adopt a flange Sealed connection with O-ring.

[0039] In this embodiment, it needs to be explained that the growth device in the example adopts the method of lifting the upper flange cover of the cavity, so the upper electrode 5 cannot be arranged in parallel with the upper flange, and can only be arranged through the upper flange. The way of flange is carried out, helps feeding material and finished product to take out like this, reduces the number of disassembly times of upper electrode 5. Conversel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com