Improved anti-pollution flashover coating and preparation method thereof

An anti-pollution flashover coating and an improved technology, applied in fire-resistant coatings, coatings, etc., can solve the problems of reduced surface energy, strong adhesion, and difficult to remove, and achieve the effects of reduced adhesion, rapid detachment, and reduced impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

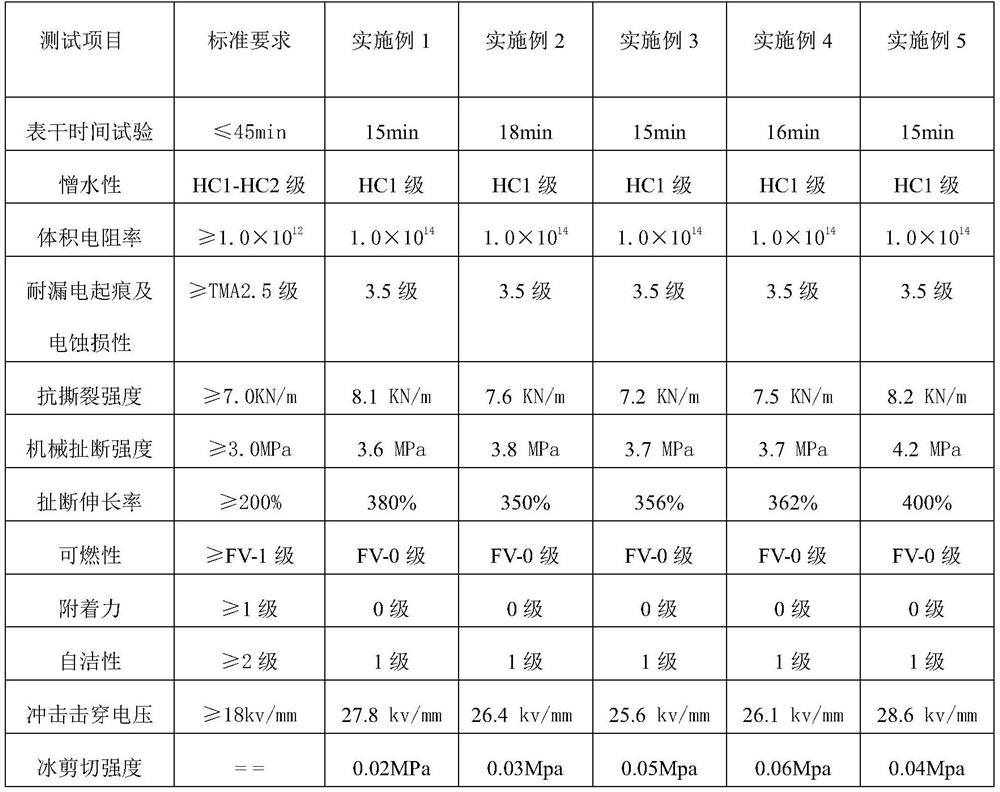

Examples

preparation example Construction

[0035] In addition, the present invention also discloses a preparation method of an improved antifouling flashover coating, comprising the following steps:

[0036] 1) According to the formulation requirements of the above-mentioned improved anti-pollution flashover coating, configure the mixed solvent;

[0037] 2) Add the formula amount of hydroxyl-terminated polydimethylsiloxane into the kneader, stir evenly at a speed of 40-60rpm, then add white carbon black, aluminum hydroxide, alumina microspheres, decabromodiphenyl For ether and pigments, adjust the rotation speed to 80-120rpm; after heating to 80-120°C, turn on the vacuum to remove air bubbles and small molecular substances, and maintain the rotation speed at 80-120rpm for 1.5-2h to make the materials in the kneader evenly mixed;

[0038] 3) After the material obtained in step 2) is cooled to room temperature, it is transferred to a three-roll machine for grinding until the grinding fineness of the material is below 20 ...

Embodiment 1

[0041] The preparation of the improved type antifouling flashover coating provided by the present invention comprises the steps:

[0042] 1) Mix the solvent No. 120 gasoline, ethyl acetate, methylene chloride and xylene in a mixing tank according to the mass ratio of 3:0.5:0.3:1 to obtain the mixed solvent in this application for subsequent use;

[0043] 2) Add 100 parts of low-viscosity hydroxyl-terminated polydimethylsiloxane and high-viscosity hydroxyl-terminated polydimethylsiloxane with a mass ratio of 2:1 into the kneader, stir evenly at a speed of 40 rpm, and then Add 10 parts of white carbon black, 30 parts of aluminum hydroxide with a particle size of 5-30 μm, 25 parts of alumina microspheres with a particle size of 15-45 μm, 18 parts of decabromodiphenyl ether and 5 parts of pigment, and adjust the rotation speed to 80 rpm; heat After reaching 80°C, turn on the vacuum to remove air bubbles and small molecular substances, and maintain it for 1.5-2 hours at a rotation ...

Embodiment 2

[0049] The preparation of the improved type antifouling flashover coating provided by the present invention comprises the steps:

[0050] 1) Mix the solvent No. 120 gasoline, ethyl acetate, methylene chloride and xylene in a mixing tank according to the mass ratio of 3:0.2:0.5:1 to obtain the mixed solvent in this application and set aside;

[0051] 2) Add 100 parts of low-viscosity hydroxyl-terminated polydimethylsiloxane and high-viscosity hydroxyl-terminated polydimethylsiloxane with a mass ratio of 3:1 into the kneader, stir evenly at a speed of 40 rpm, and then Add 15 parts of white carbon black, 45 parts of aluminum hydroxide with a particle size of 15 μm, 30 parts of alumina microspheres with a particle size of 30 μm, 20 parts of decabromodiphenyl ether and 6 parts of pigment, and adjust the rotation speed to 100 rpm; after heating to 100 ° C , turn on the vacuum to remove air bubbles and small molecular substances, and maintain it for 1.5-2 hours at a speed of 100rpm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com