Production method of colored copper alloy casting

A production method and technology of copper alloys, which are applied in the directions of casting molds, casting mold components, casting molding equipment, etc., can solve the problems of high coloring method equipment requirements, high temperature control requirements, complex coloring liquid components, etc., without pretreatment. Process, not easy to fall off, and the effect of improving anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A colored copper alloy coloring solution, the components and content per liter are: 125g of copper sulfate, 10g of ammonium chloride, 40ml of ammonia, 12ml of acetic acid, and the balance is water.

[0053] An aluminum bronze alloy for colored coloring, the composition and mass content are: Cu: balance, Sn: 0.07%, Zn: 0.7%, Pb: 0.01%, P: 0.01%, Al: 10.4%, Fe: 2.6%, Mn: 0.3%, Si: 0.1%, other impurities: 1.5%.

[0054] The production method of colored copper alloy casting, the steps are as follows:

[0055] Step 1: Fully mix and configure the above colored copper alloy coloring solution;

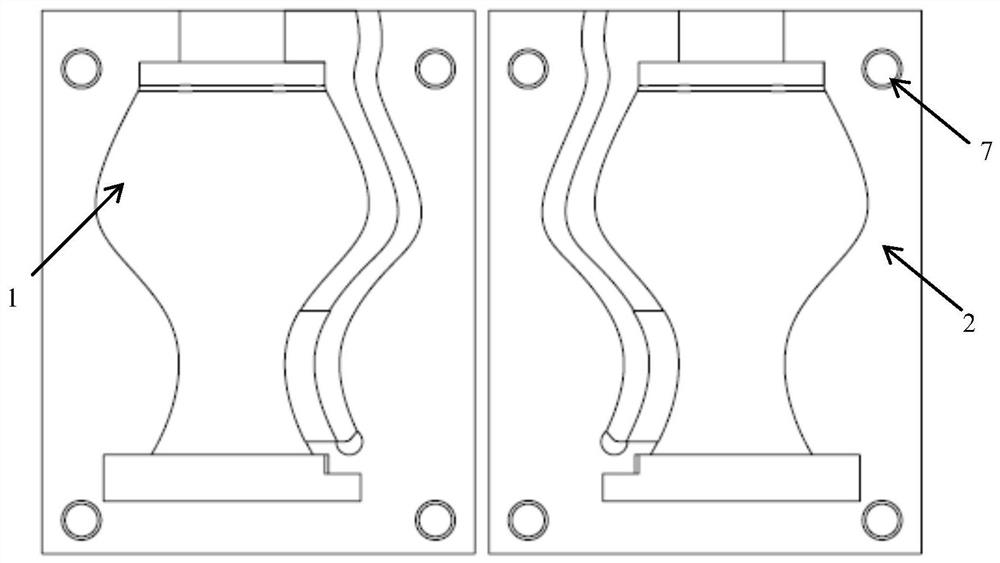

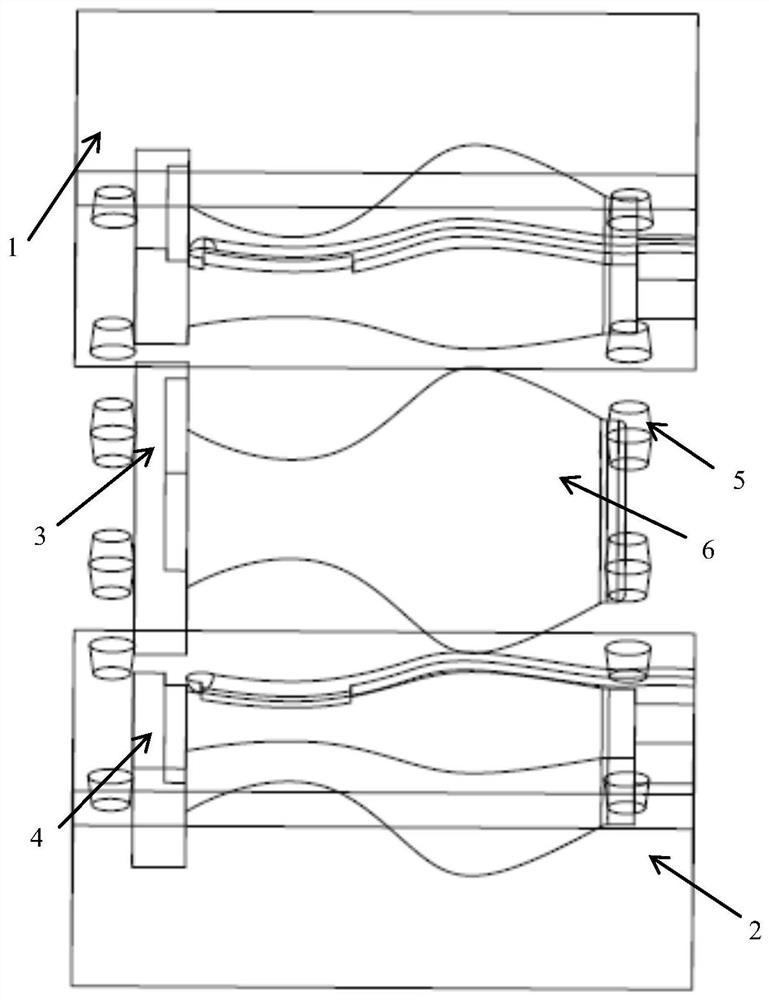

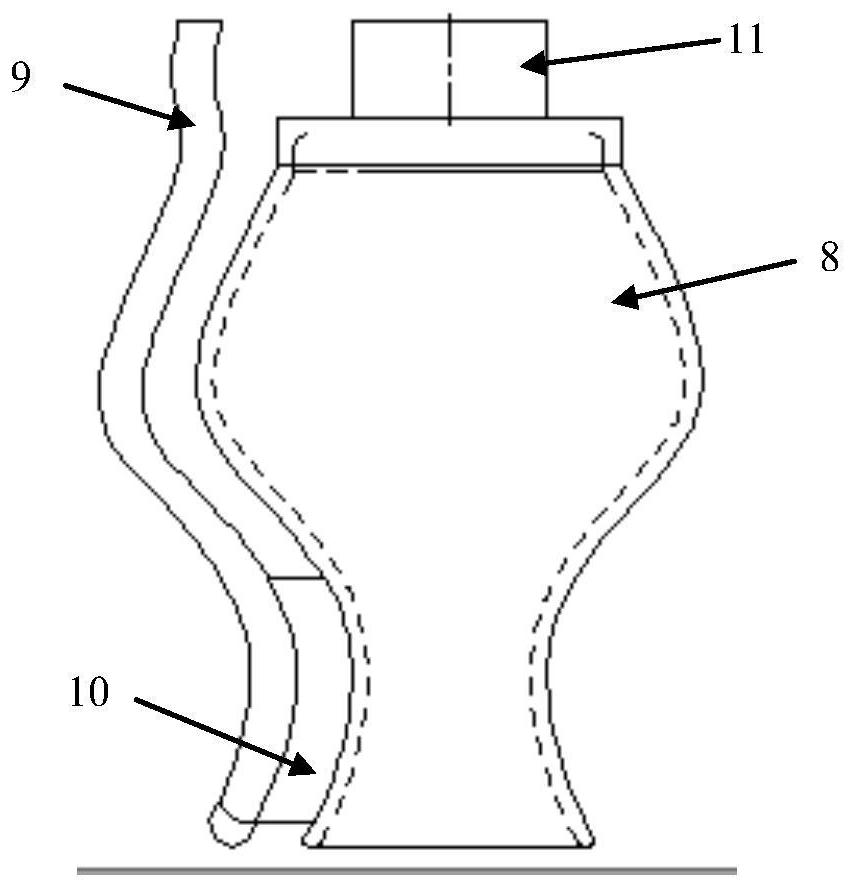

[0056] Step 2: Make a mold for pouring, polish the mold and brush the inner surface with an alcohol-based zircon powder coating with a thickness of 0.2mm. The alcohol-based zircon powder coating contains alcohol. After the coating is evenly applied, Ignite the alcohol-based zircon powder coating and dry the surface of the mold; the alcohol-based zircon powder coating is a mixture of a...

Embodiment 2

[0062] A colored copper alloy coloring solution, the components and content per liter are: 130g of copper sulfate, 12g of ammonium chloride, 38ml of ammonia, 10ml of acetic acid, and the balance is water.

[0063] An aluminum bronze alloy for colored coloring, the composition and mass content are: Cu: balance, Sn: 0.05%, Zn: 0.5%, Pb: 0.01%, P: 0.01%, Al: 10.4%, Fe: 2.6%, Mn: 0.25%, Si: 0.05%, other impurities: 1%.

[0064] The production method of colored copper alloy casting, the steps are as follows:

[0065] Step 1: Fully mix and configure the above colored copper alloy coloring solution;

[0066] Step 2: Make a mold for pouring, polish the mold and brush the inner surface with an alcohol-based zircon powder coating with a thickness of 1mm. The alcohol-based zircon powder coating contains alcohol, and the alcohol-based zircon powder coating After smearing evenly, ignite the alcohol-based zircon powder coating and dry the surface of the mold; the alcohol-based zircon powd...

Embodiment 3

[0072] A colored copper alloy coloring solution, the components and content per liter are: 135g of copper sulfate, 15g of ammonium chloride, 35ml of ammonia, 8ml of acetic acid, and the balance is water.

[0073] An aluminum bronze alloy for colored coloring, the composition and mass content are: Cu: balance, Sn: 0.1%, Zn: 1.0%, Pb: 0.006%, P: 0.008%, Al: 8%, Fe: 2.5%, Mn: 0.5%, Si: 0.08%, other impurities: 1.7%.

[0074] The production method of colored copper alloy casting, the steps are as follows:

[0075] Step 1: Fully mix and configure the above colored copper alloy coloring solution;

[0076] Step 2: Make a mold for pouring, polish the mold and brush the inner surface with an alcohol-based zircon powder coating with a thickness of 0.6mm. The alcohol-based zircon powder coating contains alcohol. After the coating is evenly applied, ignite the alcohol-based zircon powder coating and dry the surface of the mold; the alcohol-based zircon powder coating is made by mixing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com