A kind of ternary positive electrode material for lithium ion secondary battery and preparation method thereof

A technology of positive electrode material and secondary battery, applied in the field of high-nickel ternary positive electrode material and its preparation, can solve the problems of unfavorable battery, poor safety, battery safety hazards, etc. Discharge capacity, the effect of easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

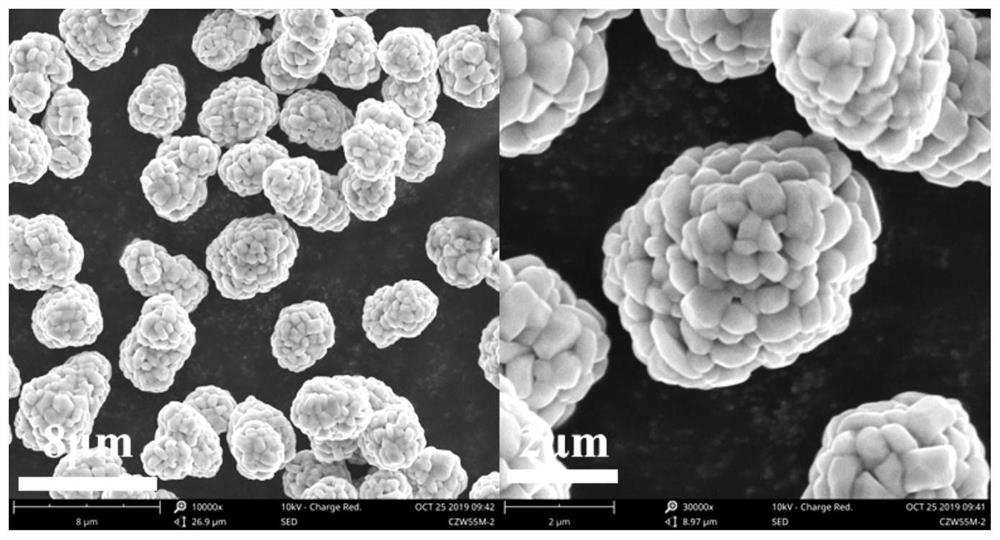

Image

Examples

Embodiment 1

[0049] step 1):

[0050] To the ternary precursor A (Ni 0.8 Co 0.1 Mn 0.1 )(OH) 2 Add 2000ppm ZrO 2 (aladin reagent) and 1000 ppm SrO (aladin reagent), to a ternary precursor B (Ni 0.8 Co 0.1 Mn 0.1 )(OH) 2 Add 800ppm ZrO 2 (aladin reagent) and 400ppm SrO (aladin reagent), mix them evenly, and then add LiOH to precursor A and precursor B according to the same molar ratio (Li:(Ni+Co+Mn)=1.02:1) ·H 2 O (manufactured by Ganfeng Lithium Industry), respectively mix well to obtain material A and material B;

[0051] After that, in an oxygen atmosphere, material A and material B were calcined at 750°C and 780°C, respectively, and both material A and material B were calcined for 10 hours, and a sintering was performed to obtain a sintered material A and a sintered material B in turn;

[0052] The ICP detection shows that the total doping mass ratio of Zr element and Sr element in the crystal structure of primary sintered material A is 2280 ppm, and the total doping mass rat...

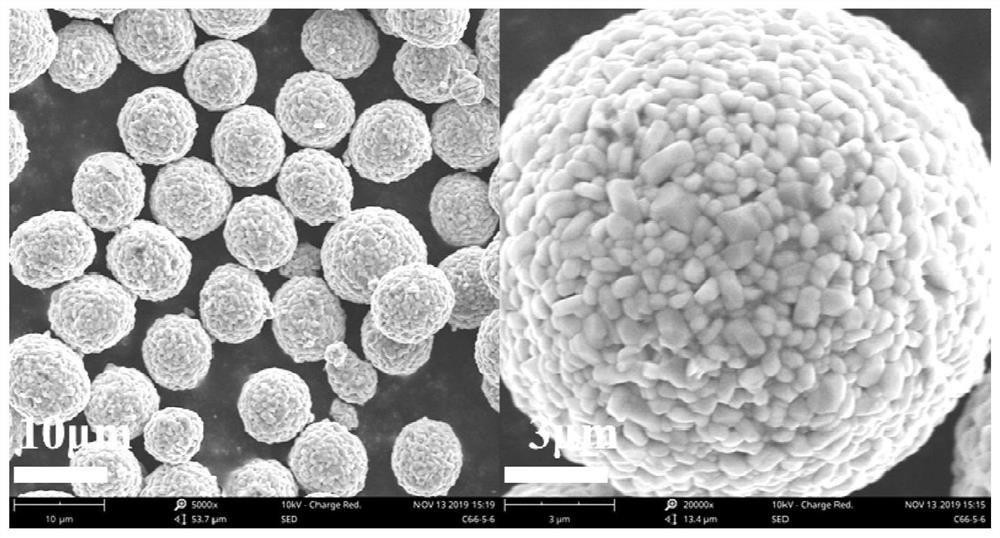

Embodiment 2

[0063] Basically the same as Example 1, the difference is that in step 1), the following changes are made: 3000ppm ZrO is added to the ternary precursor A with a median particle size of 4 μm 2 and 500ppm SrO, adding 100ppm ZrO to the ternary precursor B with a median particle size of 10μm 2 and 100ppm SrO, respectively, and mix well. Other conditions remain unchanged, the final result is a ternary cathode material with a median particle size of 7 μm, Zr doping of 1200 ppm, Sr doping of 200 ppm, and surface-coated conductive carbon accounting for 2% of the total mass. Remove the surface-coated conductive carbon. Its structural formula is: Li 1.01 Ni 0.8 Co 0.1 Mn 0.1 Zr 0.0012 Sr 0.0003 O 2 .

[0064] In this embodiment, the ICP detection shows that the total doping mass ratio of Zr element and Sr element in the crystal structure of the primary sintered material A is 2660 ppm, and the total doping mass ratio of Zr element and Sr element in the crystal structure of the p...

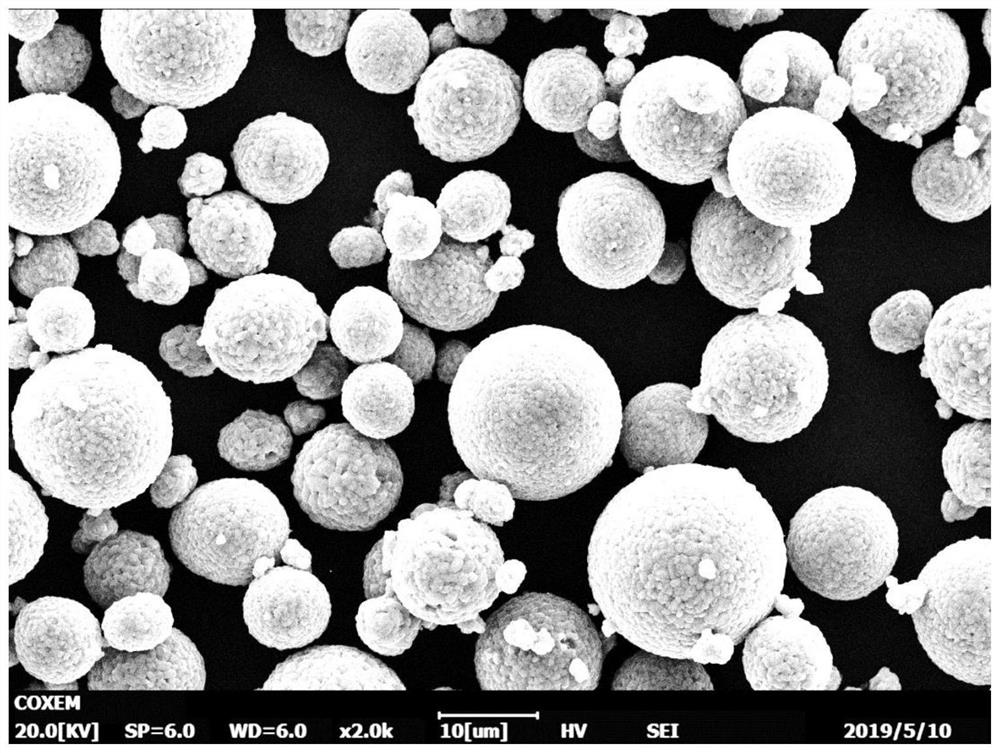

Embodiment 3

[0066] It is basically the same as Example 1, except that the following changes are made in step 1): 1000ppm ZrO is added to the ternary precursor A with a median particle size of 4 μm 2 and 500ppm SrO, adding 100ppm ZrO to the ternary precursor B with a median particle size of 10μm 2 and 1000ppm SrO, respectively, and mix well. With other conditions unchanged, the final result is a ternary cathode material with a median particle size of 7 μm, Zr doping of 300 ppm, Sr doping of 700 ppm, and surface-coated conductive carbon accounting for 2% of the total mass. Remove the surface-coated conductive carbon. Its structural formula is: Li 1.01 Ni 0.8 Co 0.1 Mn 0.1 Zr 0.0004 Sr 0.0008 O 2 .

[0067] In this example, according to ICP detection, the total doping mass ratio of Zr element and Sr element in the crystal structure of primary sintered material A is 1170 ppm, and the total doping mass ratio of Zr element and Sr element in the crystal structure of primary sintered mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com