A kind of preparation method of ammonia gas sensor based on graphene/polypyrrole

An ammonia gas sensor, polypyrrole technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of poor gas selectivity, poor repeatability, and high device power consumption, and achieve high durability, material durability, and gas selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

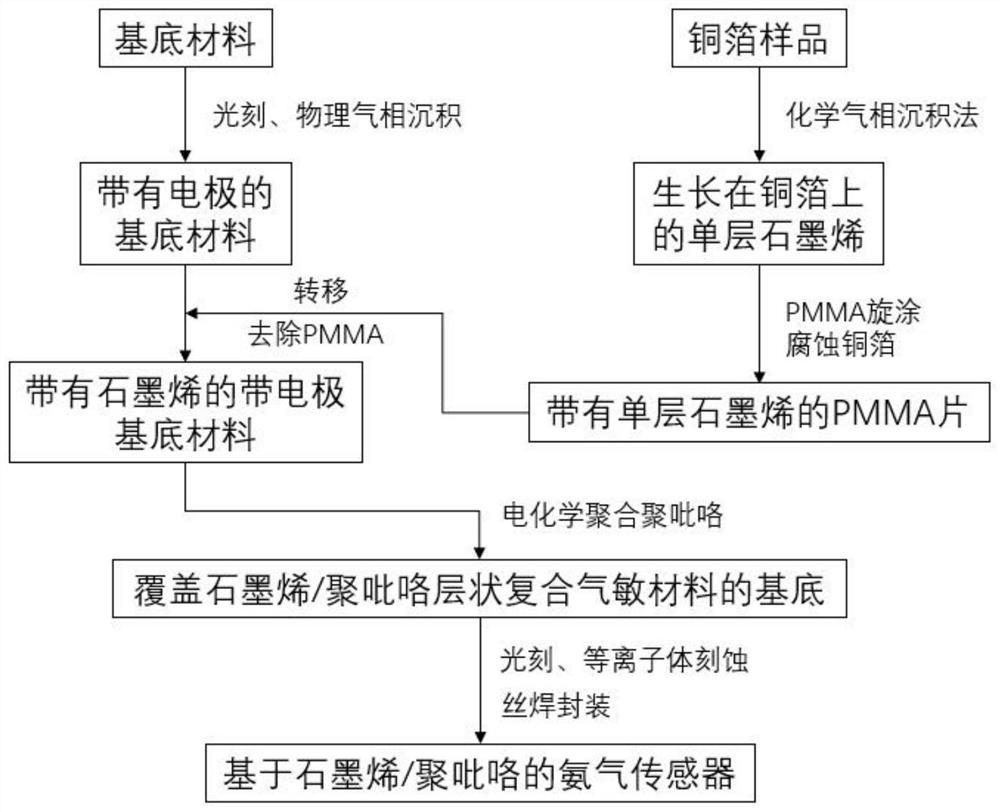

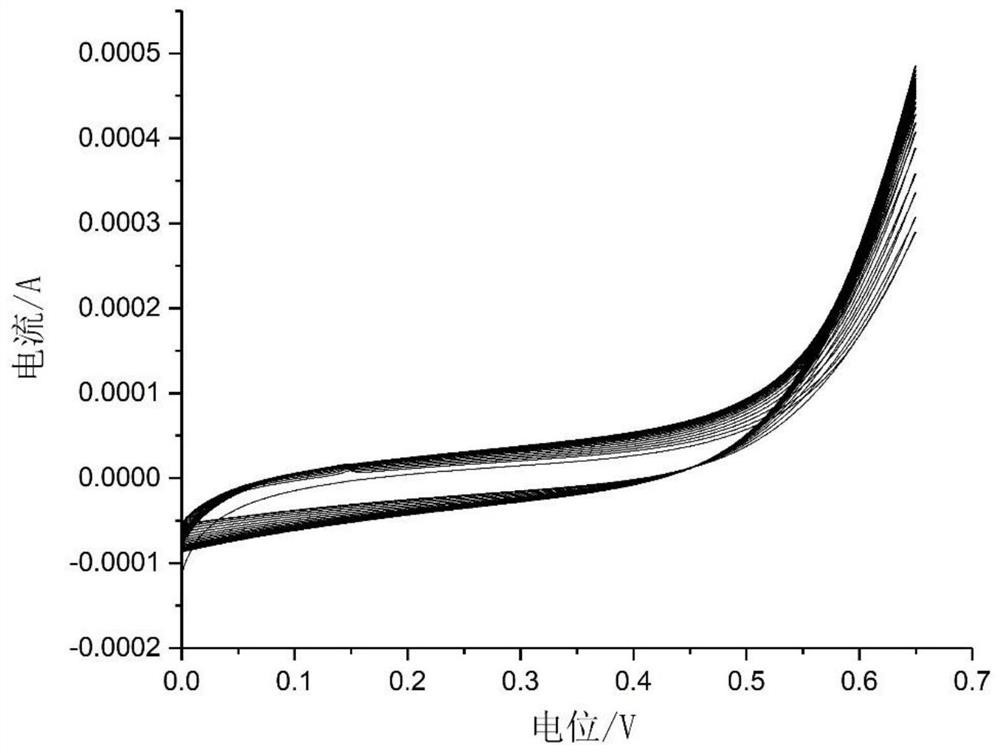

[0053] A kind of preparation method of the ammonia gas sensor based on graphene / polypyrrole, the method comprises the following steps:

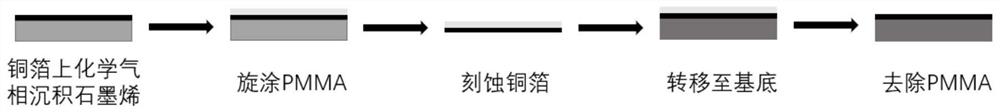

[0054] (1) Prepare a single-layer graphene film by chemical vapor deposition: cut a copper foil with a thickness of 0.3mm into a square with a side length of 50mm, clean it sequentially with acetone, isopropanol and deionized water, and then put it into argon gas in the tube furnace. Then 50 sccm of hydrogen and 50 sccm of argon were bubbled into the chamber at 1000° C. for 10 minutes. The pressure in the chamber was then reduced to 60 Pa. After entering the growth stage, 5 sccm hydrogen gas and 25 sccm methane gas were introduced to deposit single-layer graphene on the copper foil. Finally, 50 sccm of argon and 5 sccm of hydrogen were passed through the tube furnace to cool the sample to room temperature. The transparency of the prepared graphene is >95%, and the number of layers is <3.

[0055] (2) Using ultraviolet lithography technolo...

Embodiment 2

[0062] A kind of preparation method of the ammonia gas sensor based on graphene / polypyrrole, the method comprises the following steps:

[0063] (1) Prepare a single-layer graphene film by chemical vapor deposition: cut a copper foil with a thickness of 0.3mm into a square with a side length of 50mm, clean it sequentially with acetone, isopropanol and deionized water, and then put it into argon gas in the tube furnace. Then 50 sccm of hydrogen and 50 sccm of argon were bubbled into the chamber at 1000° C. for 10 minutes. The pressure in the chamber was then reduced to 60 Pa. After entering the growth stage, 5 sccm hydrogen gas and 25 sccm methane gas were introduced to deposit single-layer graphene on the copper foil. Finally, 50 sccm of argon and 5 sccm of hydrogen were passed through the tube furnace to cool the sample to room temperature. The transparency of the prepared graphene is >95%, and the number of layers is <3.

[0064] (2) Using ultraviolet lithography technolo...

Embodiment 3

[0071] A kind of preparation method of the ammonia gas sensor based on graphene / polypyrrole, the method comprises the following steps:

[0072] (1) Prepare a single-layer graphene film by chemical vapor deposition: cut a copper foil with a thickness of 0.3mm into a square with a side length of 50mm, clean it sequentially with acetone, isopropanol and deionized water, and then put it into argon gas in the tube furnace. Then 50 sccm of hydrogen and 50 sccm of argon were bubbled into the chamber at 1000° C. for 10 minutes. The pressure in the chamber was then reduced to 60 Pa. After entering the growth stage, 5 sccm hydrogen gas and 25 sccm methane gas were introduced to deposit single-layer graphene on the copper foil. Finally, 50 sccm of argon and 5 sccm of hydrogen were passed through the tube furnace to cool the sample to room temperature. The transparency of the prepared graphene is >95%, and the number of layers is <3.

[0073](2) Electrode patterns are constructed on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com