Hoisting positioning device and method for assembly type cement concrete pavement slab

A cement concrete and positioning device technology, which is applied in roads, buildings, climate change adaptation, etc., can solve the problems of difficult construction adjustment, complicated positioning, and inflexible adjustment, and achieve the effect of quality stability and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

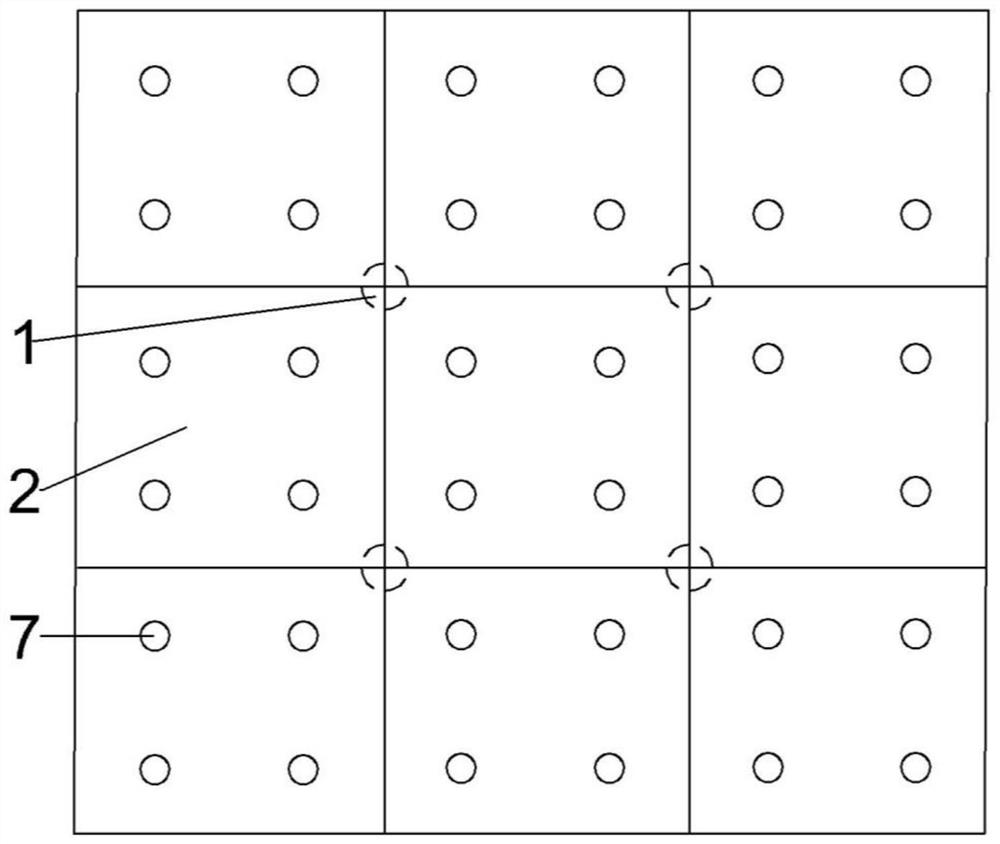

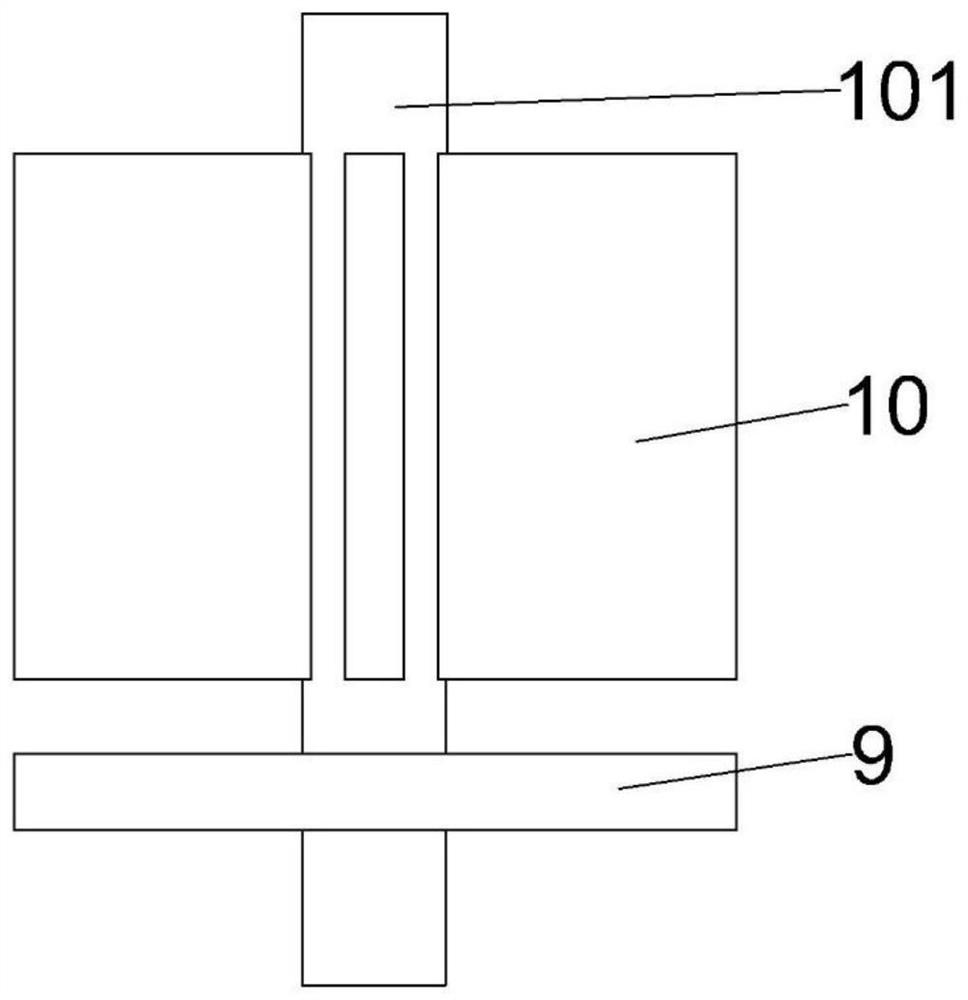

[0041] Refer Figure 1-4As shown, the present invention provides a lifting positioning device for assembling a cement concrete pave plate, including a plurality of positioning columns 1, support table 5, and the positioning column 1 and the support table 5 are respectively connected to the subgrade, and the concrete pave plate 2 is placed. At the outer circumferential direction of the positioning column 1, the outer circumferential direction of the positioning column 1 is provided with four positioning plates 10, and the four positioning plates 10 are vertically disposed, and several adjustment holes 7 are opened on the concrete floor panel 2, and the hole 7 is adjusted. Plug the guiding bracket 8, the concrete panel 2 is placed above a plurality of support tables 5.

[0042] First, the position of the positioning plate 10 is determined, the positioning plate 10 is the main reference point of the entire road construction; the positioning plate 10 can be positioned to locate the con...

Embodiment 2

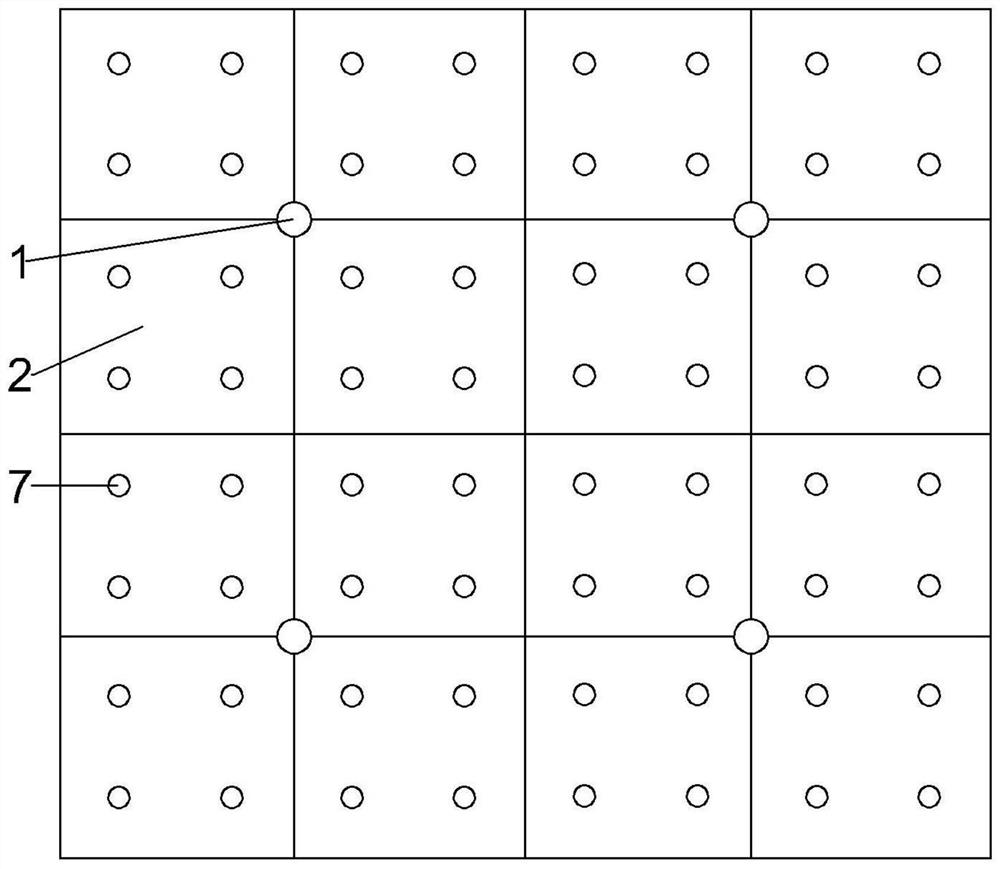

[0045] Refer Figure 3-13 As shown, the positioning method of the present embodiment and the embodiment of the embodiment is only:

[0046] Further optimizing the scheme, further comprising several sealing strips 4, several sealing strips 4 cross-fixed each other, and the plurality of support tables 5 are disposed inside the sealing strip 4, the sealing strip 4, the support table 5 fixedly connected to the subgrade, sealing strip 4, respectively, sealing strip 4 The top surface of the support station is equal to the bottom surface of the concrete panel 2. After the sealing strip 4 is mainly after the construction of the concrete floor panel 2, the slurry remains below the concrete panel 2 in the grouting process, does not leak, after mud hardening, producing a good bonding effect.

[0047] Further optimization scheme, the positioning column 1 is disposed at the center of the sealing strip 4, and the positioning column 1 is fixedly connected to the intersection of the sealing strip ...

Embodiment 3

[0070] Refer Figure 4As shown, the positioning method of the present embodiment and the second embodiment of the second embodiment is only:

[0071] If the subgrade is the soil floor, first use the measuring instrument to determine the positioning point; steps in the second to fourth cement concrete, the positioning reference, the sealing strip 4 and the support table 5 are fixed by a steel bar (not shown) in the figure, and forming a steel bar network. Find the process and the grouting process as the example one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com