Sprayable hydrogel as well as preparation method and application thereof

A hydrogel and mannan technology, which is used in pharmaceutical formulations, medical preparations with inactive ingredients, and pharmaceutical sciences, etc., can solve problems such as weak ductility, poor stability, and γ-polyglutamic acid cannot form gels. , to achieve the effect of stable performance, good ductility, simple and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

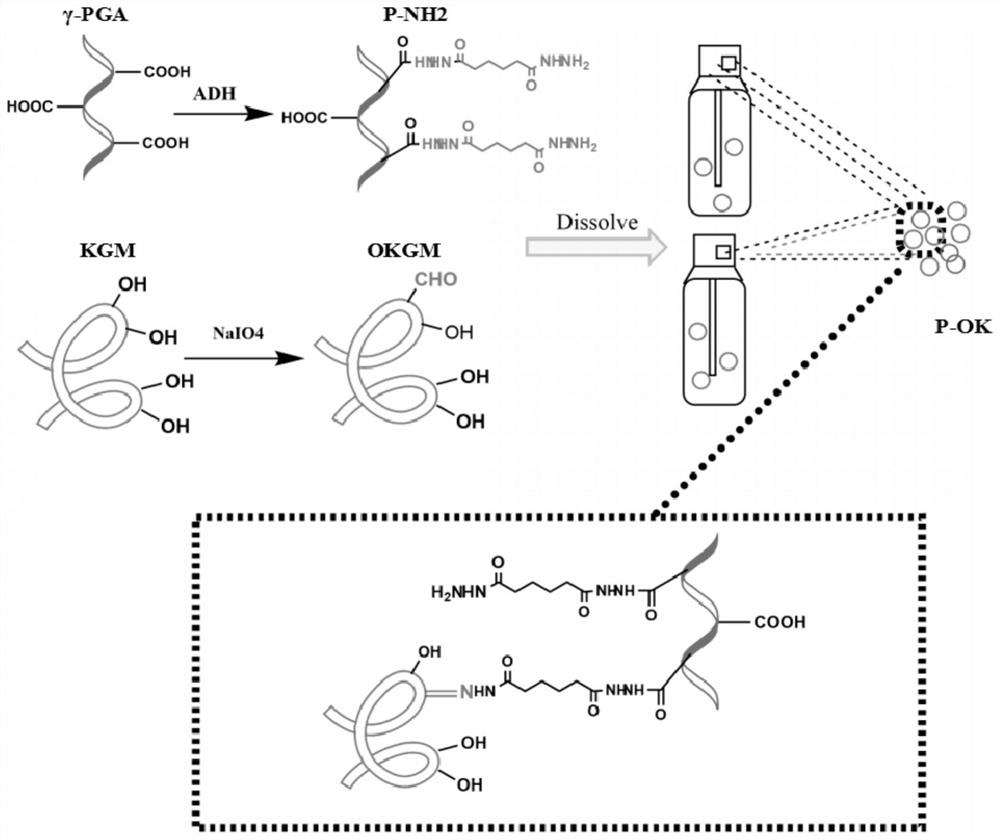

[0041] Embodiment 1: Preparation of oxidized konjac glucomannan

[0042] Add 0.5g konjac glucomannan to 500ml deionized water, stir well, then add 0.2303g sodium periodate in the dark, react at room temperature for 6 hours, add 0.6ml ethylene glycol to terminate the oxidation reaction, and dialyze with a 3kDa cellulose dialysis bag , freeze-dried to obtain oxidized konjac glucomannan (OKGM) solid, and dried for storage.

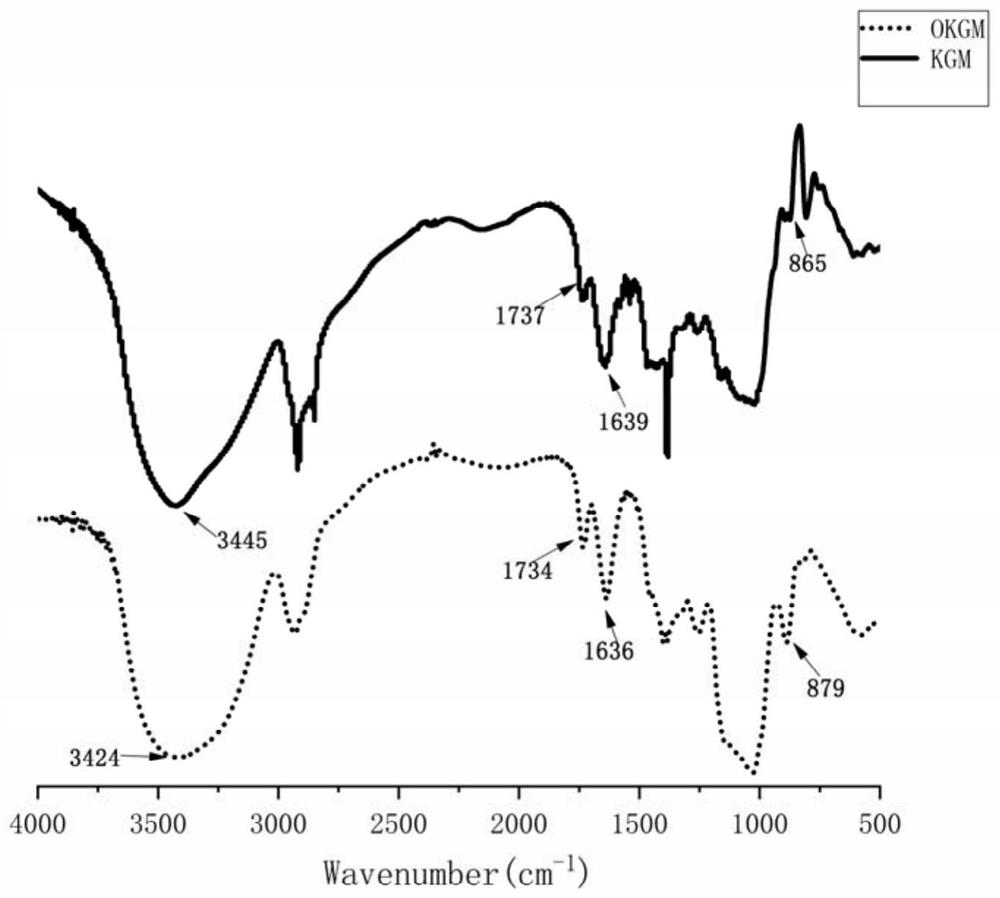

[0043] The infrared spectrogram of the oxidized konjac glucomannan prepared in the present embodiment is as follows figure 2 shown, from figure 2 It can be seen that when the sugar ring main chain remains unchanged, the 1734cm -1 The characteristic peak consists of the 1737cm of konjac glucomannan (KGM) -1 The small shoulder peak becomes a wider peak, which is the symmetrical absorption peak of the aldehyde group and the vibration superposition peak of the acetyl group. At the same time, the 879cm -1 The absorption peak of the hemiacetal structure betwe...

Embodiment 2

[0044] Embodiment 2: Preparation of modified γ-polyglutamic acid

[0045] Pour 3% γ-sodium polyglutamate solution into a glass column equipped with 732 hydrogen-type strong acid cation exchange resin, adjust the piston of the glass column to control the liquid flow rate, and the control flow rate is 2s / drop to obtain acidified γ-polyglutamate solution. - Polyglutamic acid (γ-PGA) solution, lyophilized. Add 0.1 g of acidified γ-PGA solid to 100 mL of deionized water, adjust the pH of the reaction system to 5.5 with 5% sodium hydroxide solution, and react for 10 minutes, then add 0.0580 g of EDC and 0.0348 g of NHS to the reaction liquid in turn, and react at room temperature for 20 minutes Finally, after adjusting the pH to 8, add 0.27g of adipic acid dihydrazide, react for 24 hours, add 3% hydrochloric acid solution to adjust the pH of the system to 7, terminate the reaction, dialyze with a 3kDa cellulose dialysis bag for 3 days, and freeze-dry.

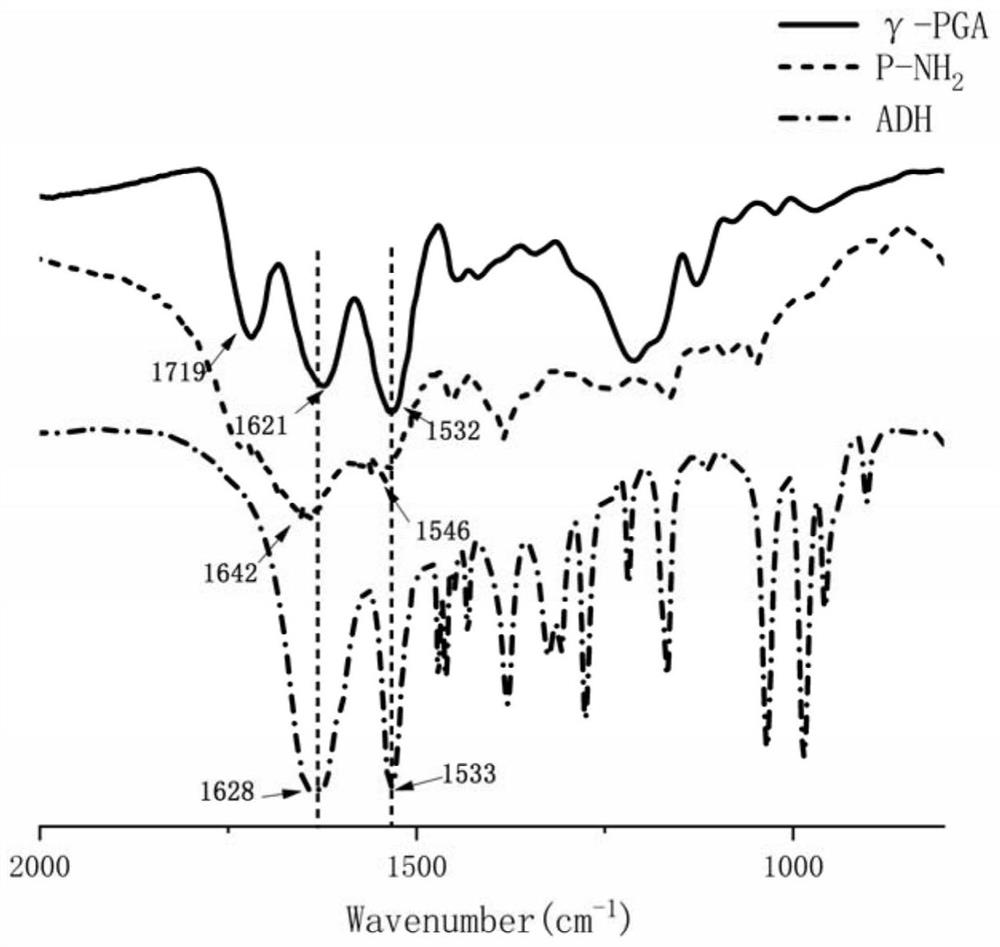

[0046] The infrared spectrog...

Embodiment 3

[0047] Embodiment 3: Hydrogel is gelled

[0048] Dissolve oxidized konjac glucomannan (OKGM) with a mass concentration of 2% in water, add methylene blue staining solution, and record it as tube A; configure a mass concentration of 5% modified γ-polyglutamic acid (P -NH 2 ) solution, denoted as tube B. At the same time, take the same volume of aqueous solution from tubes A and B into tube C, and let it stand for a while to form a sprayable hydrogel.

[0049] The sprayable hydrogel gel that present embodiment prepares is as Figure 5 As shown, it can be seen that the hydrogel is stable and mixed evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com