Method for preparing mullite from aluminum ash

A technology of mullite and aluminum ash, applied in the field of preparing mullite, can solve problems such as ecological environment hazards and accumulation, and achieve the effects of improving quality, improving resource recovery and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

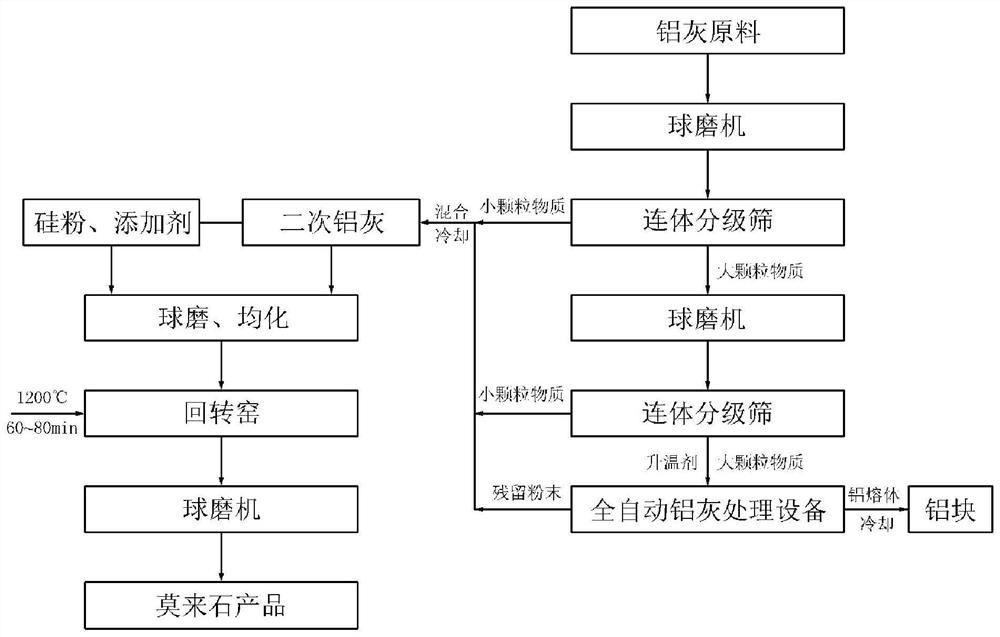

Method used

Image

Examples

Embodiment 1

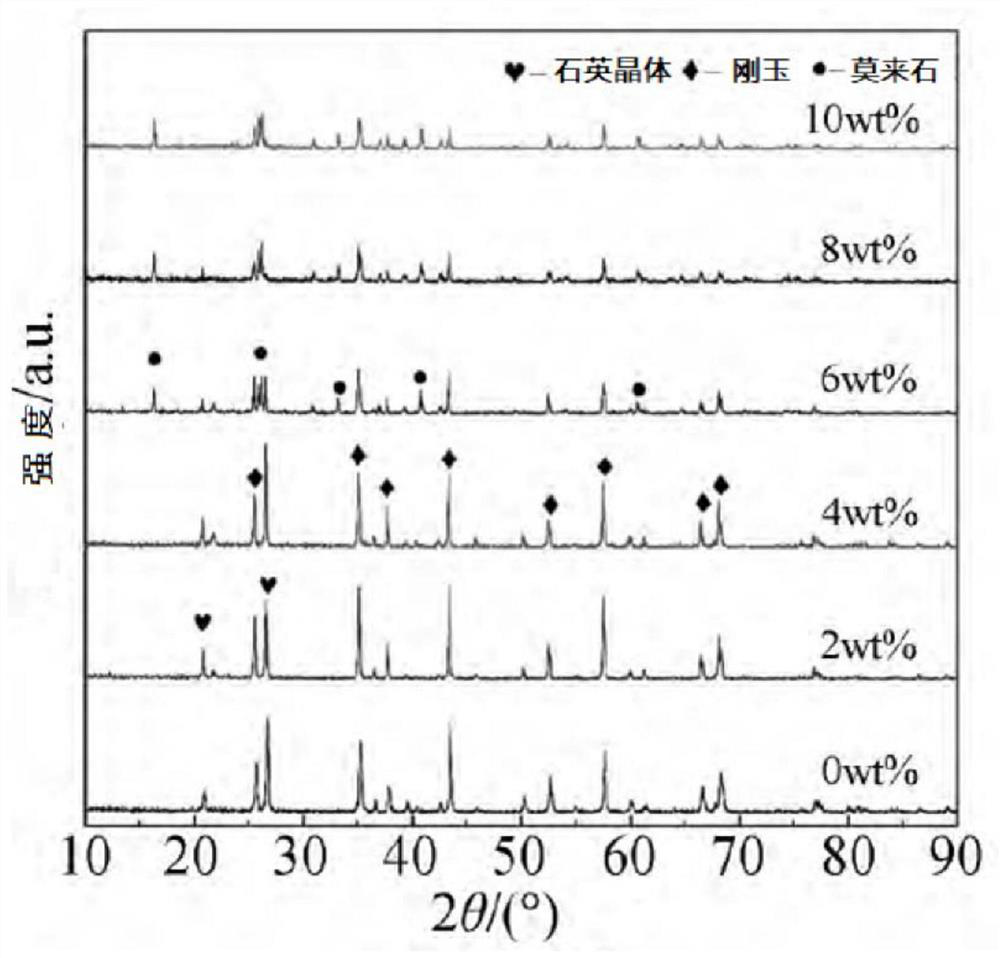

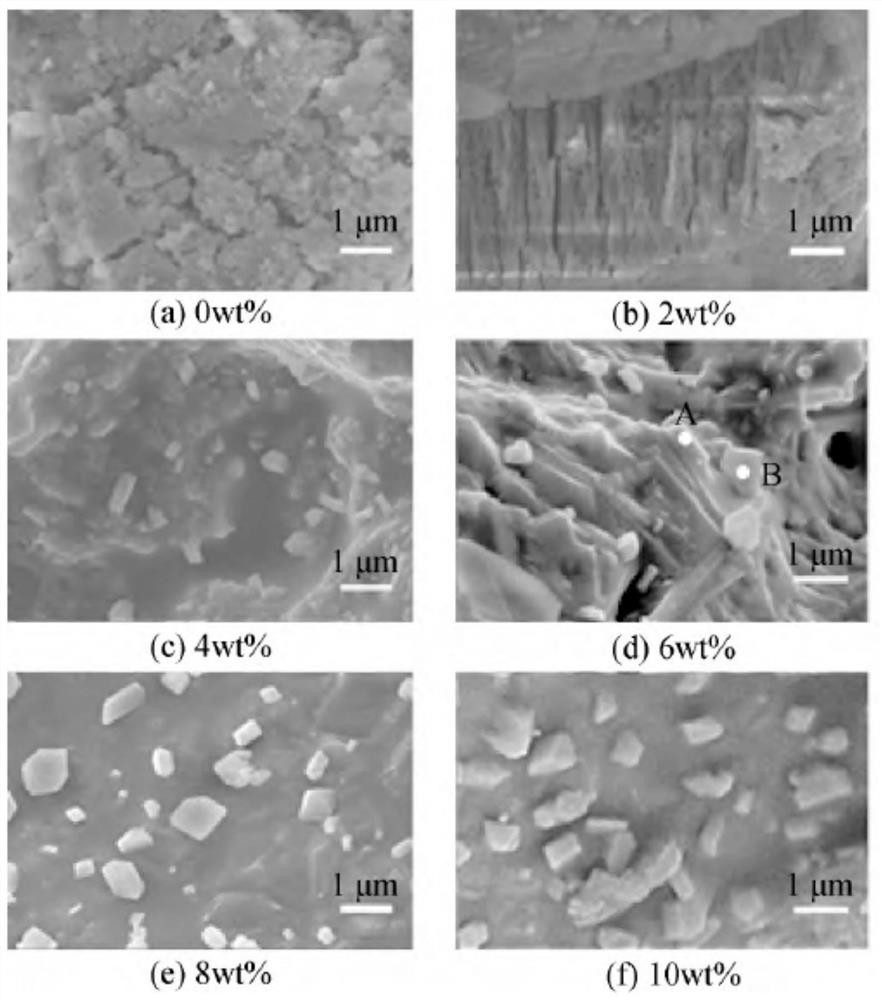

[0067] Embodiment 1 is the additive of doping 6wt%, embodiment 2 is the additive of doping 8wt%, embodiment 3 is the additive of doping 10wt%; Comparative example 1 is the additive of doping 0wt%, comparative example 2 is doping 2wt% of additives, comparative example 3 is doped with 4wt% of additives.

[0068] Example 1-Example 3 and Comparative Example 1-Comparative Example 3 all performed secondary sintering of aluminum ash according to the sintering step in the above method to form mullite. Comparative example 4 is the sintering method proposed in the document "Influence of additives on the crystal phase structure of mullite developed by aluminum plant industrial waste slag", using aluminum plant industrial waste slag and silica as raw materials, silica fume dust as a mineralizer, high temperature sintering reaction To prepare mullite, the temperature during sintering is 1480°C, and the temperature is kept for 5h. Comparative example 5 is the patent "Manufacturing method o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com