A germanium sulfide polycrystalline thin film and solar cell containing the thin film

A germanium sulfide and thin-film technology, which is applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as difficult preparation, achieve stable performance, simple operation, and great application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for preparing a high-quality thin film solar cell with a germanium sulfide polycrystalline film as an absorber layer, the specific steps include: surface selenization of base molybdenum, p-type layer deposition, n-type layer deposition, and window layer deposition steps and electrode layer deposition steps.

[0052] a) Surface Selenization of Molybdenum on the Base

[0053] The blank substrate is selected as soda-lime glass, and its surface cleaning process is as follows: ultrasonically clean with deionized water, acetone, and isopropanol for 40 minutes respectively, and then blow it with high-purity nitrogen along a fixed direction, and finally use ultraviolet- Ozone cleaning for 20min.

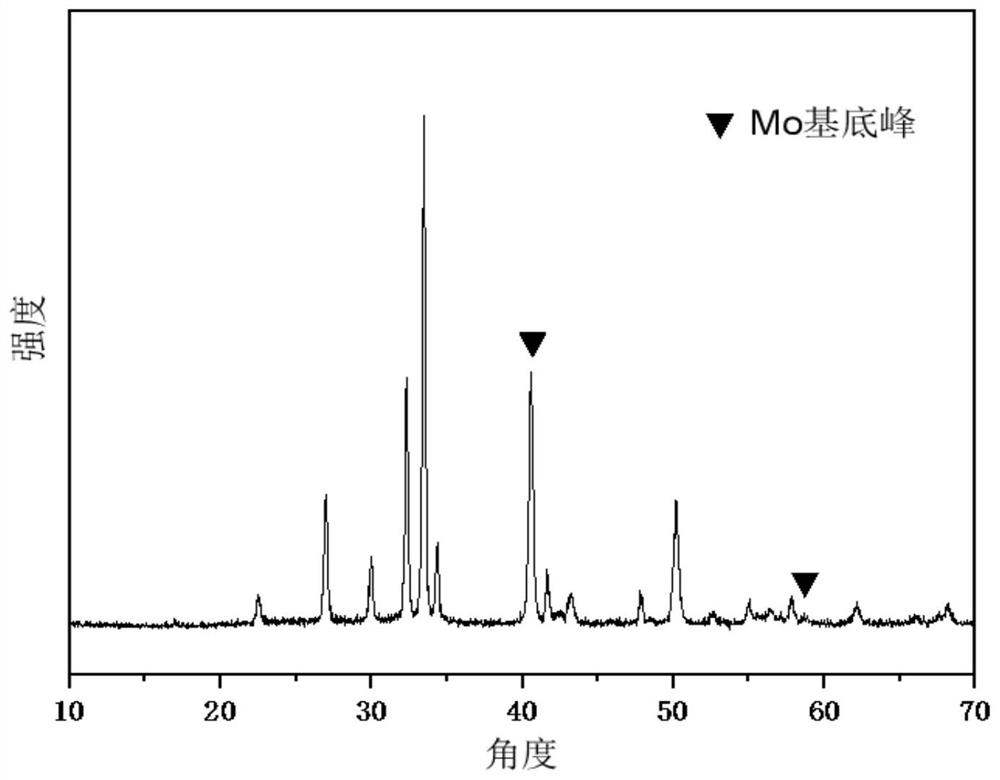

[0054] A two-step sputtering process was used to prepare the Mo base layer. First, high pressure (7mTorr) and low power (50W) were used for sputtering for 1200s. Under this condition, the film adhesion was better, but the resistance was higher; then low pressure (3mTorr) Hi...

Embodiment 2

[0063] A preparation method of a high-quality germanium sulfide polycrystalline thin film solar cell, the specific preparation method is basically the same as that in Example 1, the differences are:

[0064] In step b), the deposition procedure of the rapid annealing furnace is: C1:20, T1:15, C2:370, T2:120, C3:370, T3:600, C4:370, T4:6, C5:480, T5: 15, C6: 480, T6: 420, C7: 480, T7: -121 (wherein, the unit of C is °C, the unit of T is seconds, and T=-121 represents the termination of the program, that is, the rapid annealing furnace passes through the room temperature Rapidly heat up to 370°C in 15s, hold at this temperature for 120s, and then rapidly feed N at about 500 Torr 2 , keep the temperature for 7min, then turn on the vacuum pump, after 3min, the pressure in the deposition chamber can be pumped to below 15mTorr, then quickly heat up to 480°C after 6s, keep the temperature for 15 seconds, and finally pass in N with about 500Torr quickly again. 2 , in-situ annealing at ...

Embodiment 3

[0067] A preparation method of a high-quality germanium sulfide polycrystalline thin film solar cell, the specific preparation method is basically the same as that in Example 1, the differences are:

[0068] In step b), the deposition procedure of the rapid annealing furnace is: C1:20, T1:30, C2:410, T2:120, C3:410, T3:600, C4:410, T4:4, C5:480, T5: 15, C6: 480, T6: 420, C7: 480, T7: -121 (wherein, the unit of C is °C, the unit of T is seconds, and T=-121 represents the termination of the program, that is, the rapid annealing furnace passes through the room temperature Rapidly heat up to 410°C in 30s, hold at this temperature for 120s, and then rapidly feed N at about 500 Torr 2 , keep the temperature for 7min, then turn on the vacuum pump, after 3min, the pressure in the deposition chamber can be pumped to below 15mTorr, then it is quickly heated to 480°C after 4s, kept for 15 seconds, and finally the N of about 500Torr is quickly fed again. 2 , in-situ annealing at 480 ° C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| absorption coefficient | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com