Method for safety risk analysis of cryogenic liquid double-layer atmospheric storage tank

A technology for atmospheric storage tanks and cryogenic liquids, which is applied in special data processing applications, image data processing, 3D modeling, etc. tank control and other issues, to achieve the effect of improving efficiency and accurate analysis and detection of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

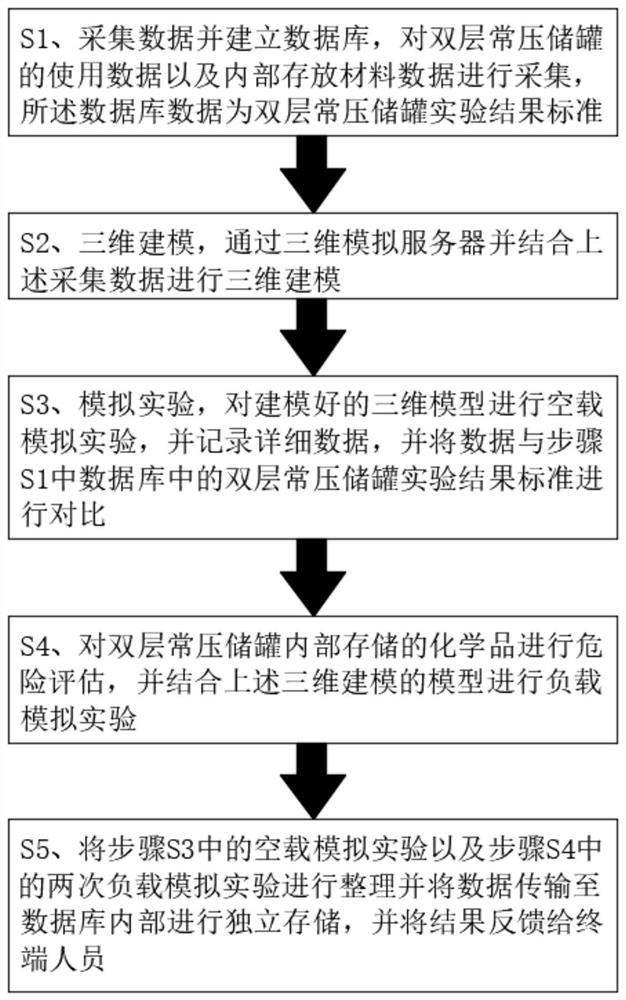

[0026] The present invention provides such figure 1 A method for safety risk analysis of a cryogenic liquid double-layer atmospheric storage tank is shown, comprising the following steps:

[0027] S1. Collect data and establish a database to collect the use data and internal storage material data of the double-layer atmospheric storage tank. The database data is the standard for the experimental results of the double-layer atmospheric pressure storage tank;

[0028] The database in step 1 also includes a hazardous chemicals database server, which includes a separate component chemical explosion hazard database and a mixture chemical explosion hazard database, which can perform real-time data transmission with the three-dimensional simulation server ;

[0029] The usage data of the double-layer atmospheric storage tank described in step S1 specifically includes: the volume, load capacity, maximum withstand pressure of the double-layer atmospheric storage tank, and information ...

Embodiment 2

[0040] On the basis of embodiment 1, the data analysis model program is included in the database, and the data analysis model program forms a multi-level data analysis layer, and performs data display on the terminal platform;

[0041] The three-dimensional laser scanner includes: a CMOS camera, an 808nm line laser, an MSP430 single-chip microcomputer, a stepping motor, a motor driver, and a casing; The resolution is 1200×1600, the frame rate is 30 frames, and the transmission interface is USB2.0. The infrared cut filter in the camera lens of the CMOS camera needs to be removed, and an 808nm high-pass filter is installed outside the camera; The 808nm one-word line laser has a laser wavelength of 808nm and a power of 500mW; the MSP430 single-chip microcomputer is a 16-bit ultra-low power consumption processor with a reduced instruction set and mixed signals;

[0042] The 3D laser scanner scans the electronic label and 3D modeling of the chemicals to be identified, and connects ...

Embodiment 3

[0044] On the basis of Example 1, the three-dimensional simulation server performs chemical shaking and explosion simulation in a three-dimensional environment, and automatically generates an identification report according to the experimental results;

[0045] The cryogenic liquid double-layer atmospheric storage tank is equipped with electronic tags with corresponding chemical parameters. The three-dimensional laser scanner can read all the electronic tags. The electronic tags are used to store and read the chemical composition information to be identified. The electronic tags One-to-one correspondence with chemicals, the parameters in the electronic label include chemical name, chemical alias, CAS number, explosive characteristics, three-dimensional model, ignition point and flash point.

[0046] After the results are fed back to the terminal personnel, the terminal personnel carry out follow-up operations according to the management principles of atmospheric storage tanks; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com