Antioxidant food preservative film and preparation method thereof

A technology for oxidizing food and fresh-keeping film, which is applied in the manufacture of rayon, chemical characteristics of fibers, textiles and paper making, etc. It can solve the problems of low protein content, increase the adsorption capacity, improve the stability, and achieve the best anti-oxidation and fresh-keeping effect of food. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

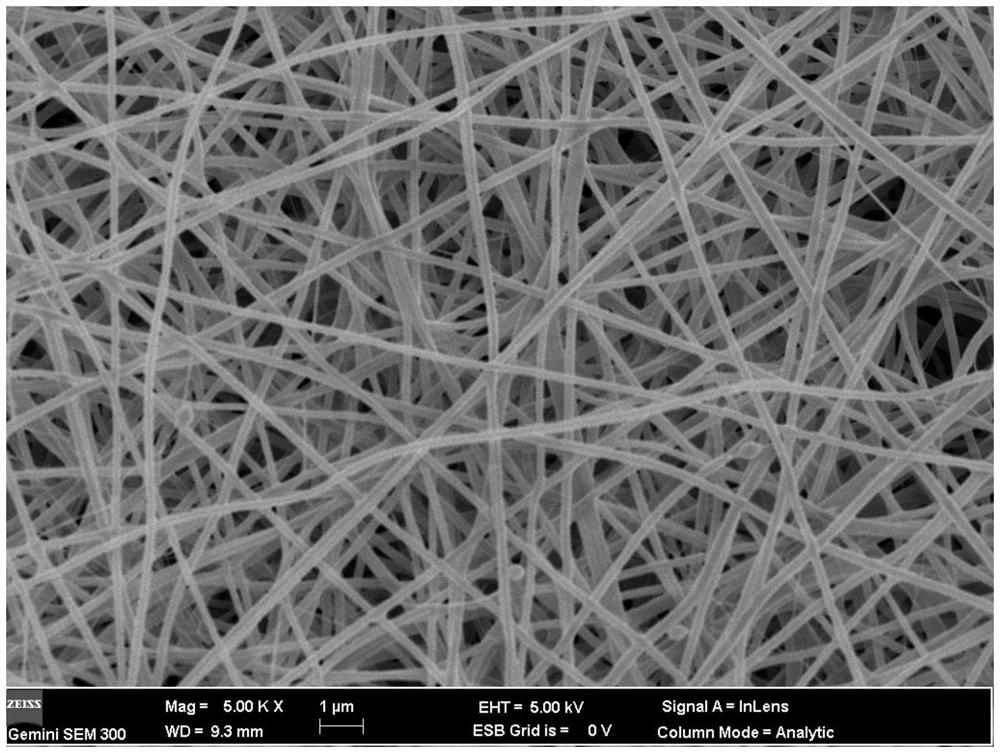

Image

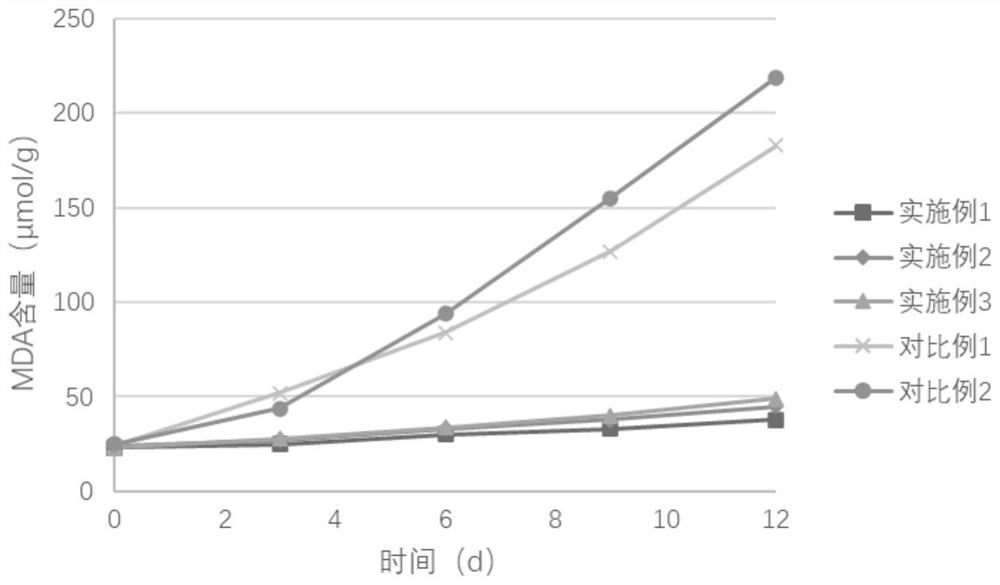

Examples

Embodiment 1

[0024] An antioxidant food preservation film and a preparation method thereof, comprising the steps of:

[0025] 1. Dissolve 30mg of lecithin-type docosahexaenoic acid in 90mL of ethanol, stir until completely dissolved, add 10g of illite powder, continue to stir to form a paste, adjust the pH value to 7.0, let stand and filter, and precipitate Washed with water 3 times, dried in vacuum to obtain organic illite powder;

[0026] 2. Dissolve 0.2g of sodium lignosulfonate, 1.1g of polyethylene oxide with an average molecular weight of 600,000, and 0.35g of polyvinyl alcohol with an average molecular weight of 50,000 and an alcoholysis degree of 88% in 50mL of water, fully dissolve to form a mixed solution ;

[0027] 3. Add 1.5g of the organic illite powder prepared in step 1 to 70mL of the epigallocatechin gallate solution with a concentration of 35g / L. After fully absorbing, filter the precipitate and dry it, and add it to the mixed solution prepared in step 2. , fully stirred...

Embodiment 2

[0031] An antioxidant food preservation film and a preparation method thereof, comprising the steps of:

[0032] 1. Dissolve 10mg of phospholipid-type eicosapentaenoic acid in 50mL of ethanol, stir until completely dissolved, add 10g of illite powder, continue to stir to form a paste, adjust the pH to 7.0, let stand and filter, and wash the precipitate with water for 3 times, vacuum-dried to obtain organic illite powder;

[0033] 2. Dissolve 0.15g of sodium lignosulfonate, 1g of polyethylene oxide with an average molecular weight of 800,000, and 0.3g of polyvinyl alcohol with an average molecular weight of 70,000 and an alcoholysis degree of 87% in 50mL of water, fully dissolve to form a mixed solution;

[0034] 3. Add 1 g of the organic illite powder prepared in step 1 to 50 mL of epigallocatechin gallate solution with a concentration of 10 g / L. After fully adsorbing, filter the precipitate and dry it, and add it to the mixed solution prepared in step 2. Stir fully and evenl...

Embodiment 3

[0038] An antioxidant food preservation film and a preparation method thereof, comprising the steps of:

[0039] 1. Dissolve 48mg of lecithin-type docosahexaenoic acid in 120mL of ethanol, stir until completely dissolved, add 10g of illite powder, continue stirring to form a paste, adjust the pH value to 7.0, let stand and filter, and precipitate Washed with water 3 times, dried in vacuum to obtain organic illite powder;

[0040] 2. Dissolve 0.25g of sodium lignosulfonate, 1.25g of polyethylene oxide with an average molecular weight of 500,000 and 0.4g of polyvinyl alcohol with an average molecular weight of 30,000 and a degree of alcoholysis of 90% in 50mL of water, fully dissolve to form a mixed solution ;

[0041] 3. Add 2 g of the organic illite powder prepared in step 1 to 80 mL of epigallocatechin gallate solution with a concentration of 55 g / L. After fully adsorbing, filter the precipitate and dry it, and add it to the mixed solution prepared in step 2. Stir fully and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com