Method for preparing xylooligosaccharide through two-step lactic acid catalytic hydrolysis

A technology for xylo-oligosaccharide and catalytic hydrolysis, which is applied in the directions of sugar production, xylose production, and sugar juice production, etc., and can solve the problem that the yield of xylo-oligosaccharide is not ideal, the yield of xylo-oligosaccharide is low, and the process is complicated. and other problems, to achieve significant economic and social benefits, increase yield, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the invention has high yield of xylooligosaccharide, simple operation, mature and reliable, no pollution, and is suitable for large-scale production.

[0023] Unless otherwise specified, the present invention has no special requirements on the sources of the raw materials involved in the above methods, and those known to those skilled in the art can be used.

[0024] In the invention, the raw materials are mixed with the lactic acid aqueous solution, the solid-liquid separation is carried out after the first catalytic reaction, and the first reaction liquid and filter residue are obtained. In the present invention, the raw material preferably includes one or more of corn cobs, corn stalks, wheat straws and poplar sawdust, more preferably corn cobs. In the present invention, the raw material is waste in the agricultural and forestry processing industry, contains cellulose and lignin, etc., can be hydrolyzed into xylooligosaccharides, and is used...

Embodiment 1

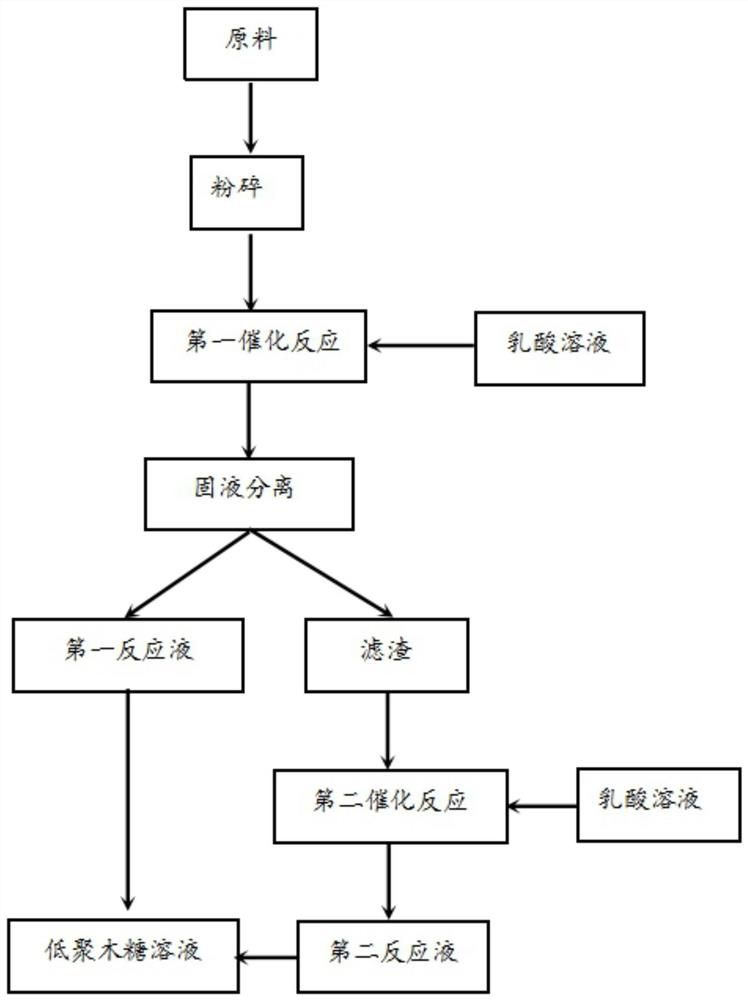

[0034] according to figure 1 Shown flow chart prepares xylo-oligosaccharide, specifically:

[0035] The first catalytic reaction: Weigh corn cobs with a crushed particle size of 0.25 mm and a dry weight of 1 gram, and add the weighed corn cobs and lactic acid with a volume concentration of 1% in the reaction kettle according to the ratio of material to liquid 1:10 solution, at a temperature of 160°C, after catalytic reaction for 40 minutes, the reaction product was cooled to 25°C in ice water, and solid-liquid separation was carried out by vacuum filtration to obtain the first reaction liquid and filter residue containing xylooligosaccharides, and the first The reaction solution.

[0036] The second catalytic reaction: Weigh the corncob filter residue with an absolute dry weight of 1 g, and carry out the catalytic reaction again according to the first catalytic condition to obtain the second reaction liquid.

[0037] The quality of xylooligosaccharides in the first reaction ...

Embodiment 2

[0045] The conditions of the two-step lactic acid catalytic hydrolysis are the same as in Example 1, except that the volume concentration of the lactic acid solution is 2%. The yields of xylobiose, xylotriose, xylotetraose, xylopentaose and xylohexaose in the first reaction solution were 18.5%, 13.5%, 13.4%, 8.5% and 6.0%, respectively, and the measured xylooligosaccharides The yield was 59.9%; the yields of xylobiose, xylotriose, xylotetraose, xylpentaose and xylohexaose in the second reaction solution were 2.8%, 2.3%, 1.4%, 1.2% and 0.7%, respectively, The measured xylo-oligosaccharide yield was 8.4%. Finally, after combining the two catalytic reaction liquids, the final yield of xylooligosaccharides was 68.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com