Comprehensive utilization method of NdFeB production wastewater

A technology for the production of waste water and products, applied in chemical instruments and methods, heating water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of wasting hydrochloric acid and iron salt resources, polluting the environment, etc., and achieve the goal of improving resources Utilization rate, high economic benefits, effect of reducing environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

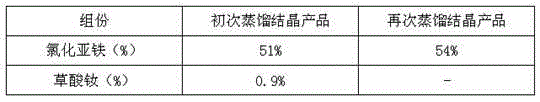

[0013] Collect the acid-containing and iron-containing waste liquid after oxalic acid precipitation, distill the waste liquid at 100°C, condense and collect the distillate, and when 83% of the water is evaporated, cool and crystallize the evaporated mother liquid to form the first distillation crystallization The product, the crystallized mother liquor is evaporated and concentrated to 50% of the original volume, and then recrystallized to generate a re-distilled crystallized product, and the mixed condensed distillate is collected. The primary distillation and crystallization product is ferrous chloride with a content higher than 50% and neodymium oxalate containing about 1%, which can be sold as an industrial grade ferrous chloride product and used as a flocculant for wastewater treatment; the secondary distillation crystallization product is a content higher than 53 % ferrous chloride, which meets the specifications of reagent grade ferrous chloride, can be used as a chemica...

Embodiment 2

[0014] Embodiment two: processing effect

[0015] In a 1000mL three-neck flask, add 600mL of grass sediment filtrate (containing 0.5mol / L hydrochloric acid and 120g / L iron (calculated as ferrous chloride)) of a certain NdFeB production wastewater, connect a 30cm long snake-shaped condenser externally, and heat the mantle power It is 1000w. Use multiple 50mL volumetric flasks to collect the condensate, and each 50mL is a sample, which is used to analyze the change of the concentration of hydrochloric acid in the condensate with the amount of distillate. After 83% of the water is evaporated from the grass filtrate (the specific gravity of the mother liquor is 1.42), the evaporated mother liquor is cooled and crystallized, and the crystallization product is distilled for the first time. After the crystallized mother liquor is evaporated and concentrated to 50% of the original volume, the recrystallized product is re-distilled and crystallized. The composition of the crystalline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com