Microcapsule, microencapsulated scale and/or fiber and preparation method and application thereof

A technology of microcapsules and flakes, applied in coatings, epoxy resin coatings, etc., can solve the problems of less performance improvement of composite materials, change of mechanical properties, poor controllability, etc., to avoid coating defects and improve coating density anti-sticking and aggregation-avoiding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] One aspect of the embodiments of the present invention provides a method for preparing microcapsules, comprising:

[0029] providing a first emulsion comprising a functional material, a self-curing resin monomer, an emulsifier and a solvent, wherein the emulsified droplet diameter of the first emulsion is 0.1-5.0 μm;

[0030] mixing the first emulsion with polymer monomers and an acid to form a first mixture;

[0031] mixing the first mixture with an oxidizing agent and reacting at 10-40°C for 4-10 hours to obtain a second mixture;

[0032] And, mixing the second emulsion containing functional materials, self-curing resin monomers, emulsifiers and solvents with the second mixture and reacting at 10-40°C for 4-10 hours to obtain microcapsules, wherein the second emulsion The emulsified droplet diameter is 5.0-15μm.

[0033] In some more specific embodiments, the preparation method includes:

[0034] The functional material is mixed with the self-curing resin monomer t...

Embodiment 1

[0106] (1) The polyphenylene sulfide fiber with a length of 10 mm and a fineness of 50 μm is treated with plasma first, and then the polyphenylene sulfide fiber is soaked in an ethanol solution containing 10 wt % coupling agent KH590, and the temperature is kept at 50 ° C , reflux and stir for 40min, then cool, filter, wash and dry to obtain A;

[0107] (2) Add the mixture of 3wt% mercaptobenzothiazole and hydroxymethylated bisphenol A diglycidyl ether successively to water (wherein the mass of mercaptobenzothiazole and hydroxymethylated bisphenol A diglycidyl ether ratio of 1:1) and 0.5wt% of span80 and tween60 (the mass of span80 and tween60 is 5:1), ultrasonically disperse first, and then stir at high speed to control the emulsified droplet diameter to 0.1μm, and the dispersion is uniform After standing still, B is obtained;

[0108] (3) Add the mixture of 6wt% mercaptobenzothiazole and hydroxymethylated bisphenol A diglycidyl ether successively to water (wherein the ratio...

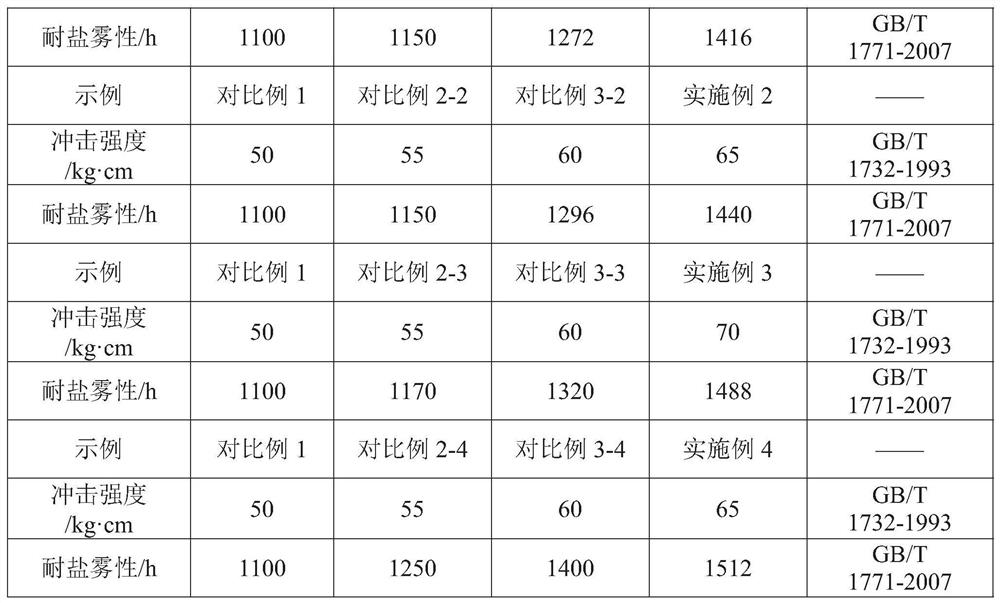

Embodiment 2

[0117] (1) The ceramic fiber with a length of 5 mm and a fineness of 10 μm is first treated with plasma surface, and then the ceramic fiber is soaked in an ethanol solution containing 30 wt% coupling agent KH580, and the temperature is kept at 80 ° C, refluxed and stirred for 20 minutes and then cooled , filtered, washed and dried to obtain A;

[0118] (2) Add 6wt% of pyridine quaternary ammonium salt and N, N'-two-(p-hydroxybenzyl)-ethylenediamine diglycidyl ether mixture (wherein pyridine quaternary ammonium salt and N, N'- Two-(p-hydroxybenzyl)-ethylenediamine diglycidyl ether has a mass ratio of 3:1) and a compound formed by 2wt% span80 and tween65 (the mass ratio of span80 and tween65 is 1:1), and ultrasonic Disperse, then stir at a high speed, control the diameter of the emulsified droplet to 5 μm, disperse evenly and let stand to obtain B;

[0119] (3) Add 10wt% pyridinium quaternary ammonium salt and N, N'-di-(p-hydroxybenzyl)-ethylenediamine diglycidyl ether mixture ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com