Recyclable eugenol-based epoxy resin Vitrimer material and preparation method thereof

A technology of eugenol-based epoxy resin and dithiodibutyric acid, which is applied in recycling technology, plastic recycling and other directions, can solve problems such as difficult recycling and reuse, and achieves narrow molecular weight distribution, mild preparation conditions and high product purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

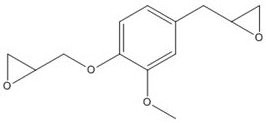

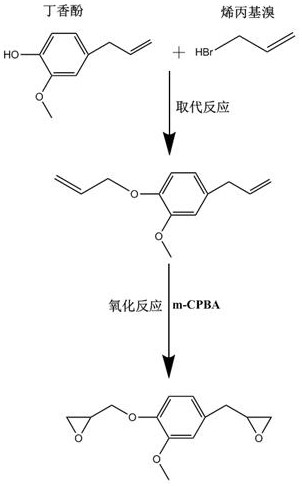

[0034] The preparation of step 1, eugenol base epoxy resin:

[0035] In the reactor, by mass, add 50 parts of allylated eugenol, 150-200 parts of m-chloroperoxybenzoic acid and 600-1000 parts of solvent, and then stir at a speed of 200-300 rpm while stirring at 20 The epoxidation reaction was carried out at -25°C for 16-40 h. After the reaction, add saturated sodium bicarbonate solution to wash 2-3 times, and saturated sodium sulfite to wash 1-2 times, then dry over anhydrous magnesium sulfate, filter and rotary evaporate to obtain the target product eugenol-based epoxy resin.

[0036] Step 2, the preparation of eugenol base epoxy resin Vitrimer material:

[0037]By mass, 40-100 parts of eugenol-based epoxy resin, 20-50 parts of dicarboxylic acid without dynamic disulfide bond, 20-50 parts of 4,4'-dithiodibutyric acid and 0.1- 0.5 parts of the transesterification accelerator are mixed evenly at a temperature of 60-65°C, then poured into a self-made dumbbell-shaped mold and u...

Embodiment 1

[0041] Step 1: Preparation of eugenol-based epoxy resin

[0042] In the reactor, by mass, add 50 parts of allylated eugenol, 150 parts of m-chloroperoxybenzoic acid and 600 parts of acetone, and then stir at a speed of 200 rpm, and carry out cyclone at a temperature of 25 ° C. Oxidation reaction 16h. After the reaction is finished, add saturated sodium bicarbonate solution to wash 2-3 times, and saturated sodium sulfite to wash 1-2 times, then dry through anhydrous magnesium sulfate, filter and rotary evaporate to obtain the target product eugenol-based epoxy resin. The rate is 95.2%.

[0043] Step 2: Preparation of eugenol-based epoxy resin Vitrimer material

[0044] By mass, 50 parts of eugenol-based epoxy resin, 10 parts of azelaic acid, 40 parts of 4,4'-dithiodibutyric acid and 0.3 parts of transesterification accelerator 1,5,7-triazepine Cyclo[4.4.0]dec-5-ene was first mixed uniformly at a temperature of 65°C, then poured into a self-made dumbbell-shaped mold and used ...

Embodiment 2

[0046] Step 1: Preparation of eugenol-based epoxy resin

[0047] In the reactor, by mass, add 50 parts of allylated eugenol, 150 parts of m-chloroperoxybenzoic acid and 600 parts of acetone, and then stir at a speed of 200 rpm, and carry out cyclone at a temperature of 25 ° C. Oxidation reaction 16h. After the reaction is finished, add saturated sodium bicarbonate solution to wash 2-3 times, and saturated sodium sulfite to wash 1-2 times, then dry through anhydrous magnesium sulfate, filter and rotary evaporate to obtain the target product eugenol-based epoxy resin. The rate is 95.2%.

[0048] Step 2: Preparation of eugenol-based epoxy resin Vitrimer material

[0049] By mass, 50 parts of eugenol-based epoxy resin, 20 parts of azelaic acid, 30 parts of 4,4'-dithiodibutyric acid and 0.3 parts of transesterification accelerator 1,5,7-triazepine Cyclo[4.4.0]dec-5-ene was first mixed uniformly at a temperature of 65°C, then poured into a self-made dumbbell-shaped mold and used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com