Smoking, frying and baking oil fume pollutant emission reduction device

A technology of pollutants and oil fume, applied in the direction of combined devices, gas treatment, membrane technology, etc., can solve the problem of low emission reduction effect of oil fume fine particles, and achieve the effect of ensuring flue gas and increasing adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

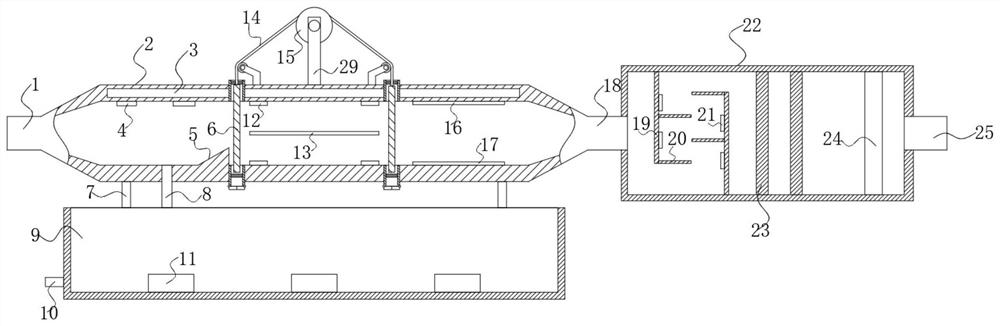

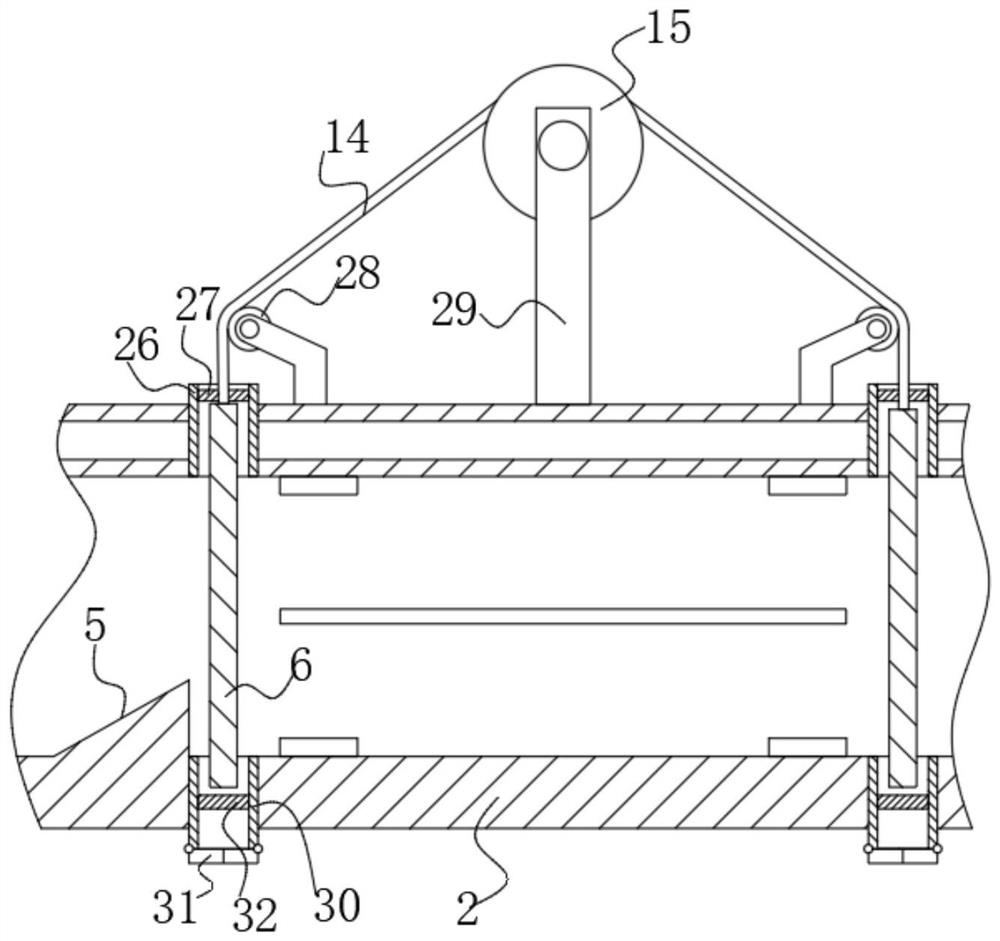

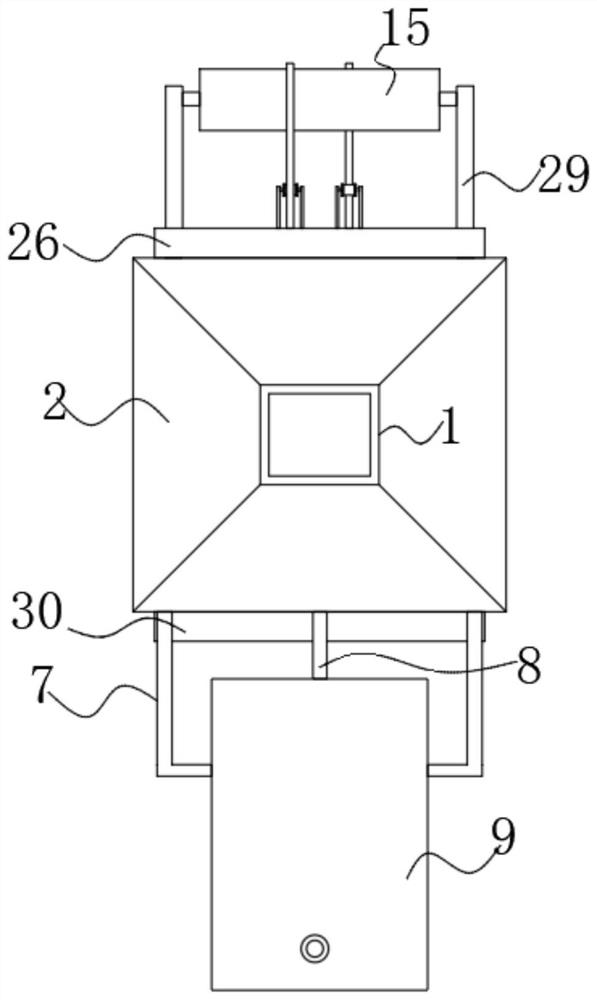

[0024] see Figure 1~3 , the present embodiment, a fumigation and roasting oil fume pollutant emission reduction device, comprises a clean box shell 2, the two ends of the clean box shell 2 have an air inlet 1 and an air outlet 18, and also includes a 1. The atomizer 4, the ultrasonic coagulation unit and the electrostatic deposition unit are sequentially arranged in the clean box shell 2 toward the air outlet 18. The air outlet 18 end of the clean box shell 2 is connected with a box body 22. The box body 22 is provided with a photocatalytic oxidation unit, a plasma catalytic oxidation assembly 23 and a terminal filter unit, the terminal filter unit is an activated carbon fiber filter screen 24, and an exhaust port 25 is installed on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com