Method for reducing discharge of flue gas pollutants in iron ore sintering process

A sintering process and pollutant technology, applied in separation methods, chemical instruments and methods, electrostatic effect separation, etc., can solve the problems of reducing nitrogen oxide emissions, low nitrogen oxide emission reduction efficiency, etc. Effective reduction and effective emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

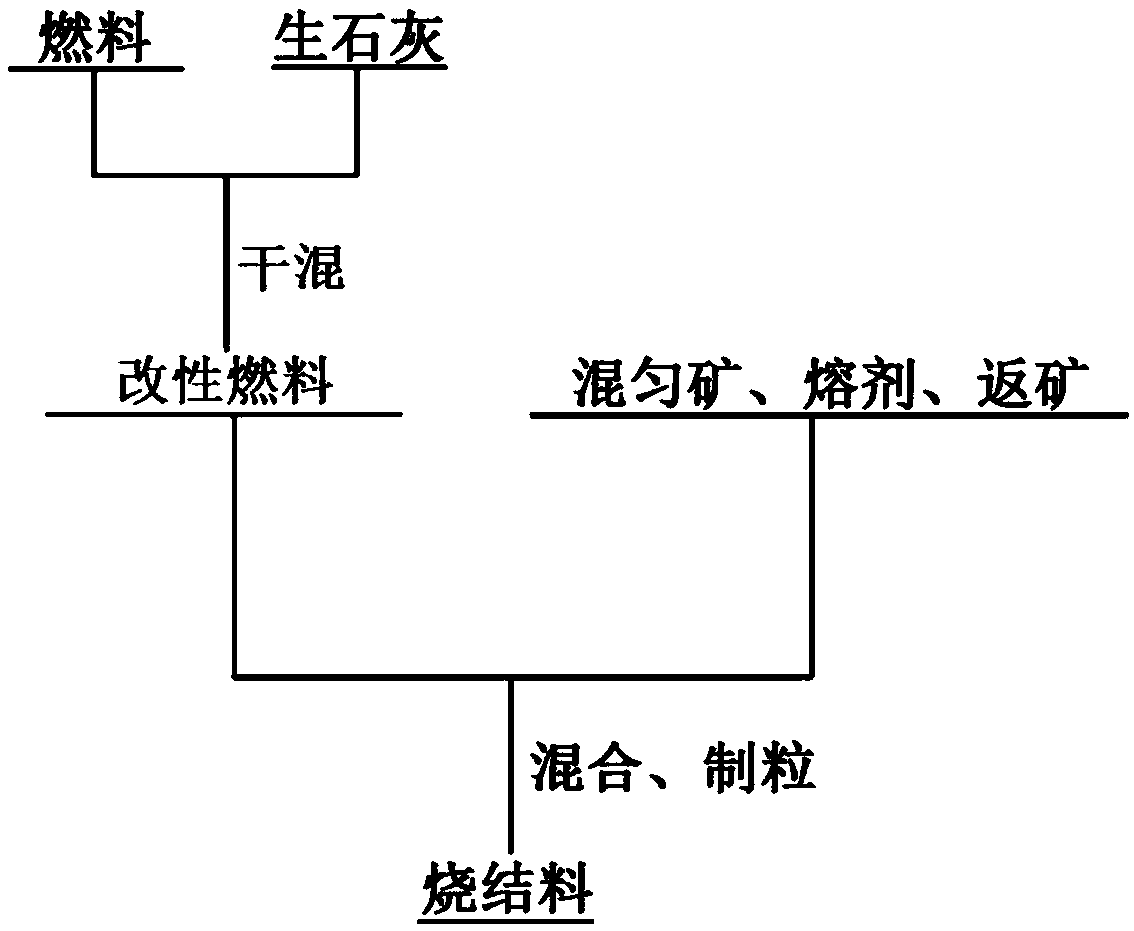

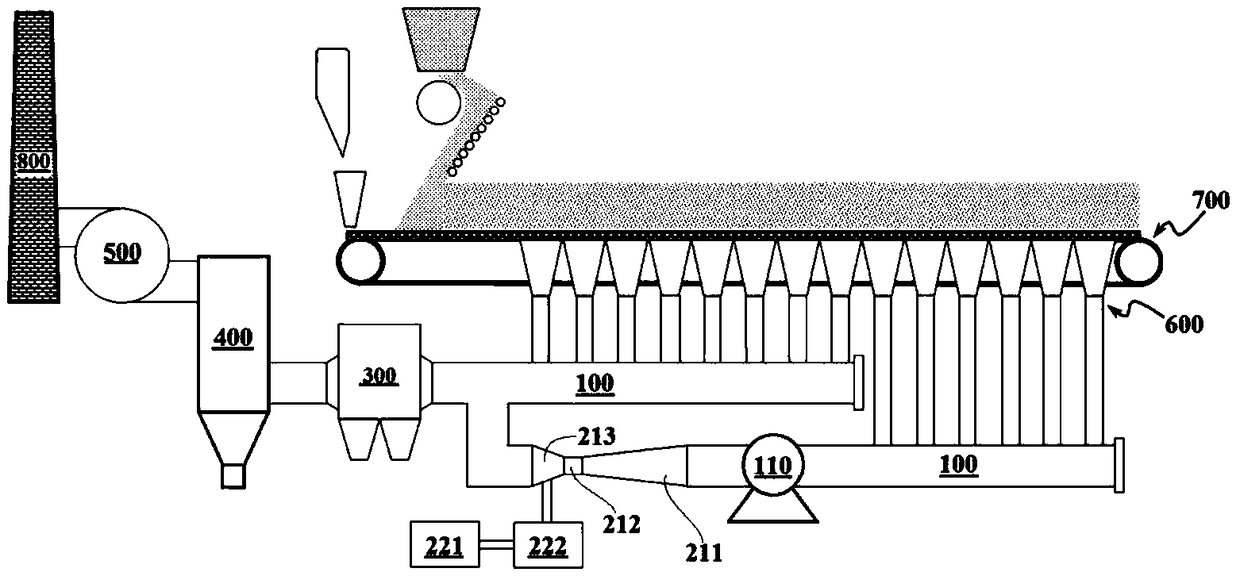

[0041] Such as Figure 1~2 Shown, the emission reduction method of a kind of iron ore sintering process flue gas pollutant of the present invention, the steps are:

[0042] (1) Fuel modification treatment

[0043] Add quicklime to the fuel for dry mixing without adding water to prepare modified fuel; the specific steps are: under dry conditions, first add the fuel to the mixer, and then add quicklime to the fuel , dry-mix quicklime and fuel, avoid adding water during the mixing process, wherein the quality of quicklime is 0.25% of the total mass of fuel, and the proportion of quicklime with a particle size of less than 200 meshes is not less than 80%. This embodiment The fuel is coke powder; here, it is worth noting that the mixer needs to be dried if it is wet.

[0044] (2) Preparation of sintered material

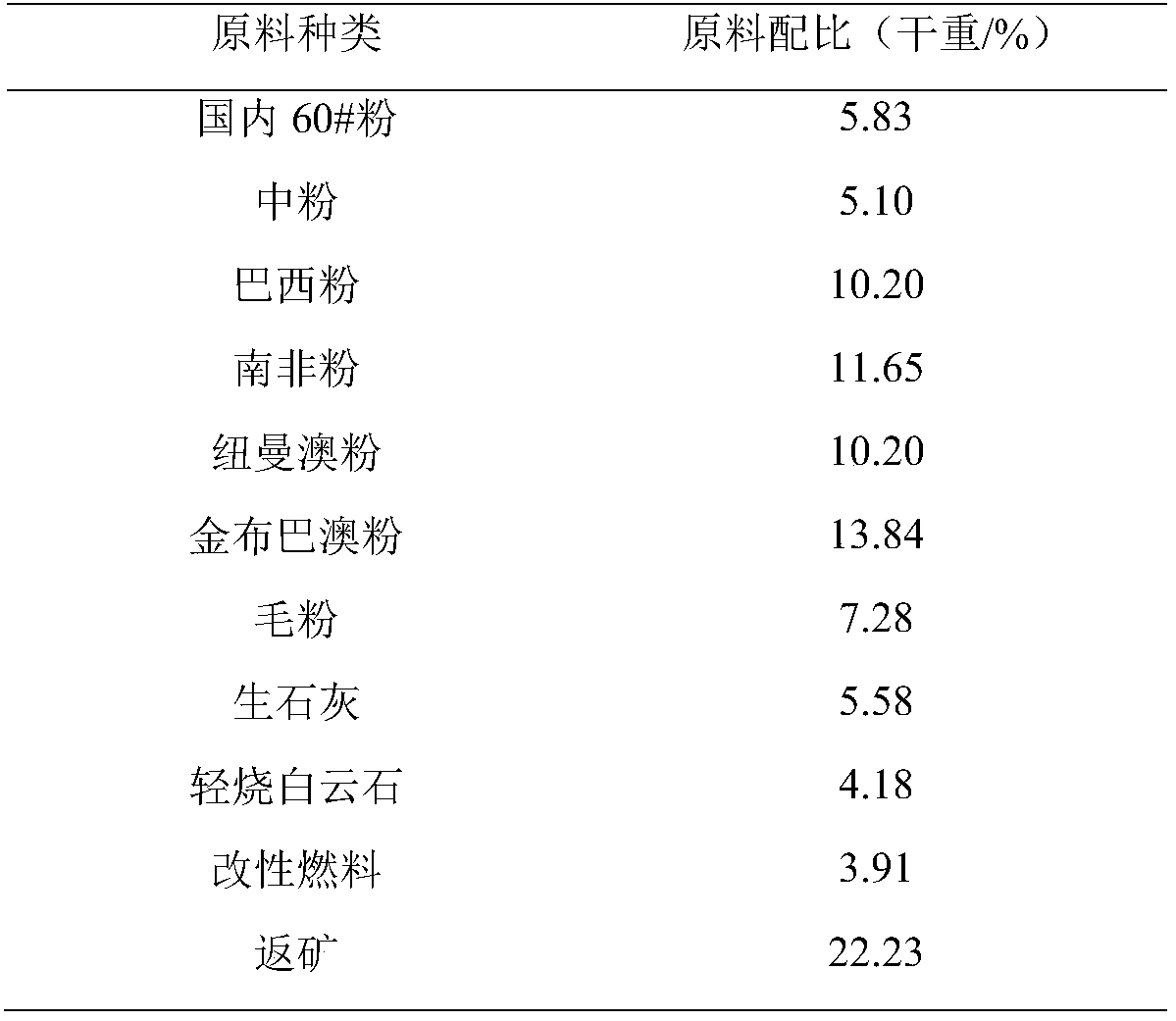

[0045] The iron-containing raw materials, flux and modified fuel are mixed and granulated to obtain a mixture; the iron-containing raw materials may include iron ore p...

Embodiment 2

[0053] The basic content of this embodiment is the same as that of Example 1, except that the mass ratio of the fuel with a particle size of less than 1.0 mm to the fuel with a particle size greater than 1.0 mm in step (1) is: 1 to 1.86, the particle size of the fuel in this embodiment The composition is shown in Table 2, wherein the mass ratio of the fuel with particle size less than 1.0 mm to the fuel with particle size greater than 1.0 mm in this embodiment is 1.

[0054] Put the mixed material on the trolley, ignite the mixed material, ventilate and sinter, and detect the NO in the sintering flue gas in the main sintering flue gas pipeline X content, and recorded as shown in Table 5.

[0055] The particle size composition of the fuel of table 2 embodiment 2

[0056]

Embodiment 3

[0058] The basic content of this embodiment is the same as that of Example 1, except that the mass ratio of the fuel with a particle size of less than 1.0 mm to the fuel with a particle size greater than 1.0 mm in step (1) is: 1 to 1.86, the particle size of the fuel in this embodiment The composition is shown in Table 3, wherein the mass ratio of the fuel with a particle size of less than 1.0 mm to the fuel with a particle size greater than 1.0 mm in this embodiment is 1.5.

[0059] Put the mixed material on the trolley, ignite the mixed material, ventilate and sinter, and detect the NO in the sintering flue gas in the main sintering flue gas pipeline X content, and recorded as shown in Table 5.

[0060] The particle size composition of the fuel of table 3 embodiment 3

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com