Waste gas recirculation method and device based on desulfurization tower for ship diesel engine

A technology for marine diesel engine and exhaust gas recirculation, which is applied in the fields of marine diesel engine exhaust gas recirculation and marine diesel engine exhaust gas recirculation system, can solve the problems of high cost, complicated installation, large renovation cost, etc., and achieves simple installation, low cost, and NOx reduction. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

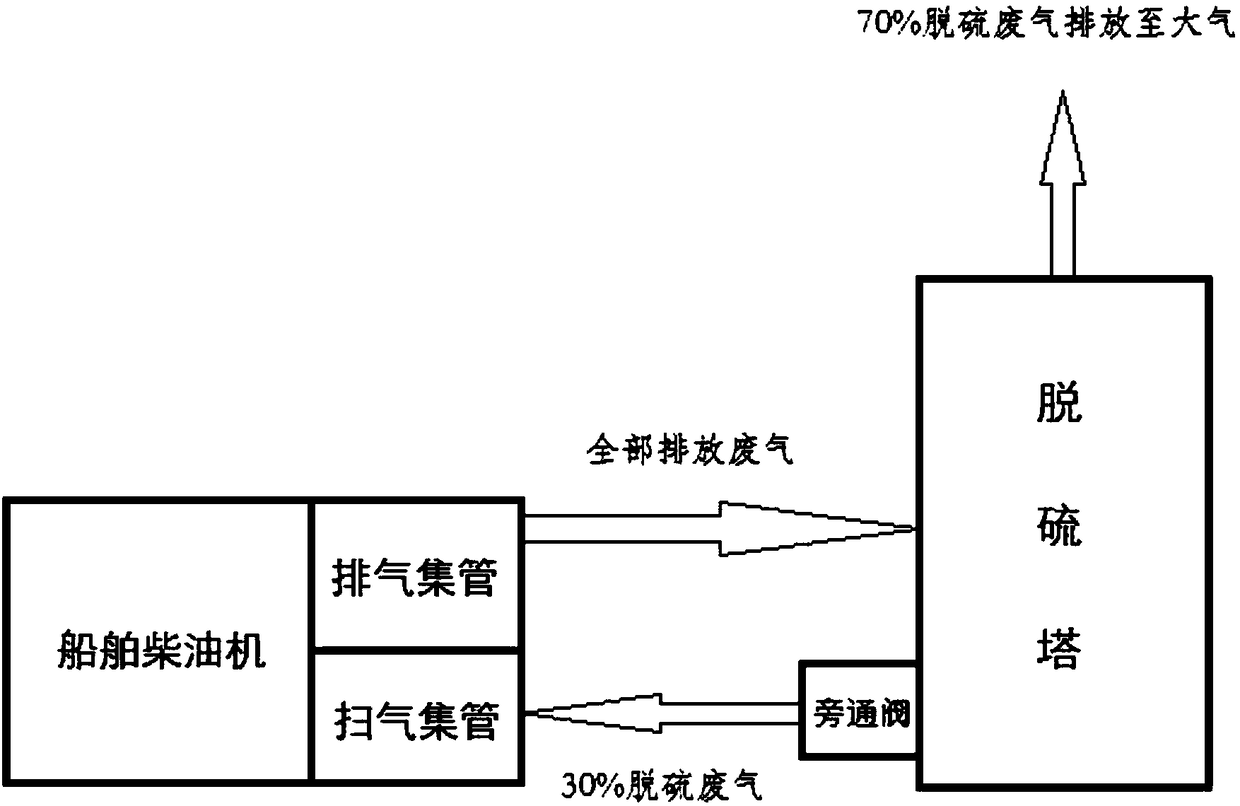

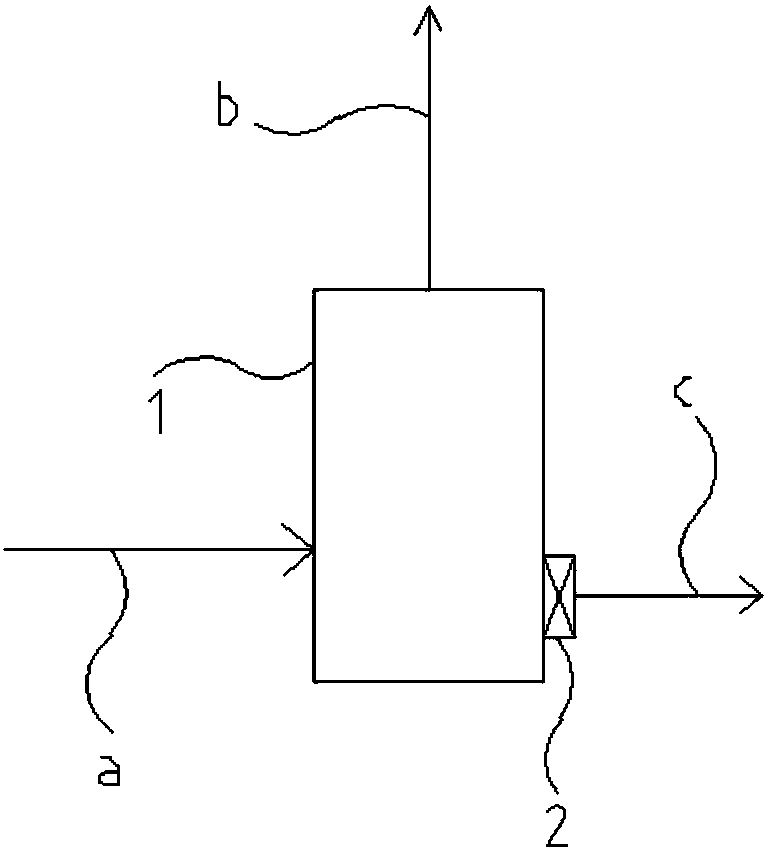

[0022] see figure 2 , the diagram shows that the exhaust gas recirculation device for marine diesel engines based on the desulfurization tower includes a desulfurization tower 1, a bypass valve 2, a diesel exhaust pipe a, an exhaust pipe b and a return pipe c.

[0023] The desulfurization tower 1 is installed downstream of the marine diesel engine, and communicates with the exhaust header of the marine diesel engine through the diesel engine exhaust pipe a, so as to discharge all exhaust gas from the marine diesel engine in the desulfurization tower 1. Desulfurization washing. The exhaust pipe b is connected to the top of the desulfurization tower 1 to discharge 70% of the desulfurized waste gas to the atmosphere. The bypass valve 2 is arranged at the bypass flue opening of the desulfurization tower 1, one end is connected to the desulfurization tower 1, and the other end is connected to the suction end of the turbocharger of the marine diesel engine through the return pipe ...

Embodiment 2

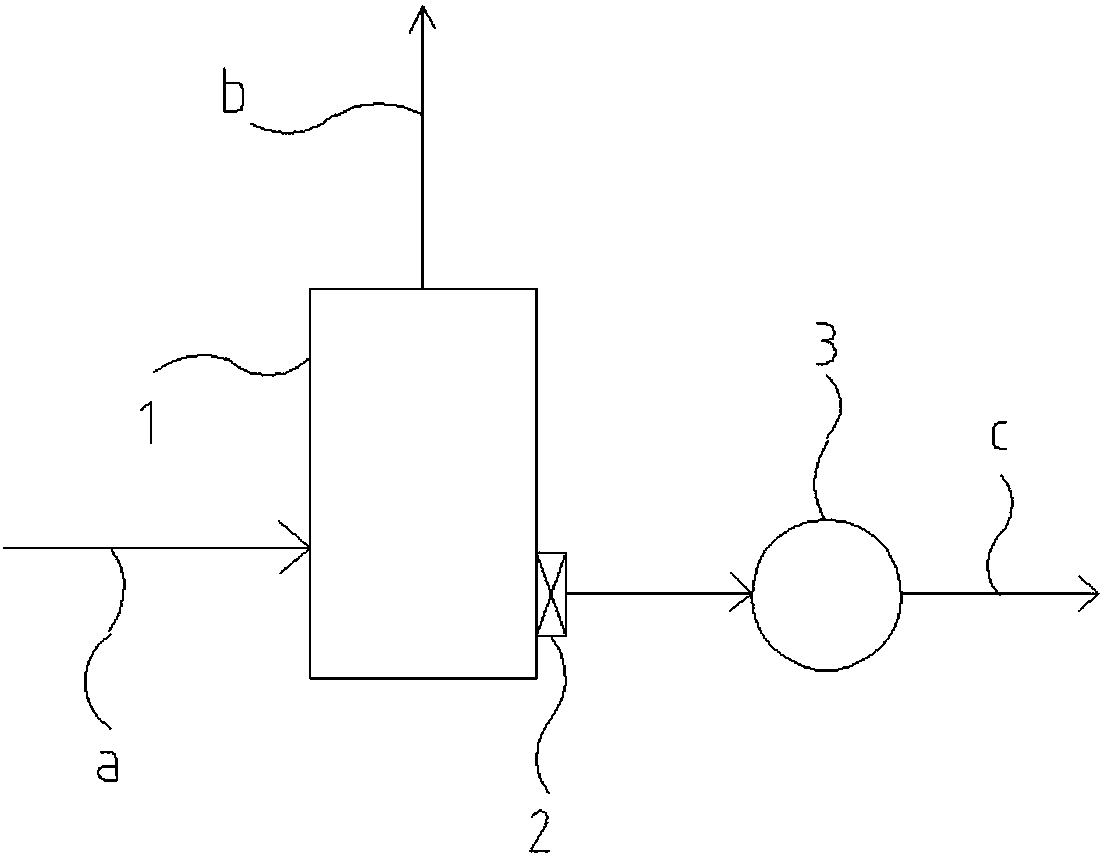

[0029] The structure of this embodiment is basically the same as that of Embodiment 1, except that a fan is also included. see image 3 , the figure shows that the marine diesel exhaust gas recirculation device based on the desulfurization tower includes a desulfurization tower 1, a bypass valve 2, a fan 3, a diesel engine exhaust pipe a, an exhaust pipe b, and a return pipe c; the fan 3 is installed in the bypass The downstream of the valve 2 is connected between the bypass valve 2 and the air return pipe c for forcibly pressurizing the desulfurized exhaust gas. The air return pipe c is directly connected to the scavenging manifold of the marine diesel engine.

[0030] During operation, the fan 3 forcibly pressurizes the desulfurized waste gas after the bypass valve 2, and sends about 30% of the bypassed desulfurized waste gas to the scavenging header of the diesel engine through the return pipe c, and the scavenging gas The fresh air in the header mixes and again participat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com