Ammonia method-SCR (Selective Catalytic Reduction) combined desulfurization and denitrification system and method

A technology of desulfurization and denitrification and ammonia desulfurization, applied in the field of sintering pollutant emission reduction, can solve the problems of low cost of sintering flue gas, high cost of denitrification, low efficiency, etc., and achieve the effect of reasonable utilization and low cost joint emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

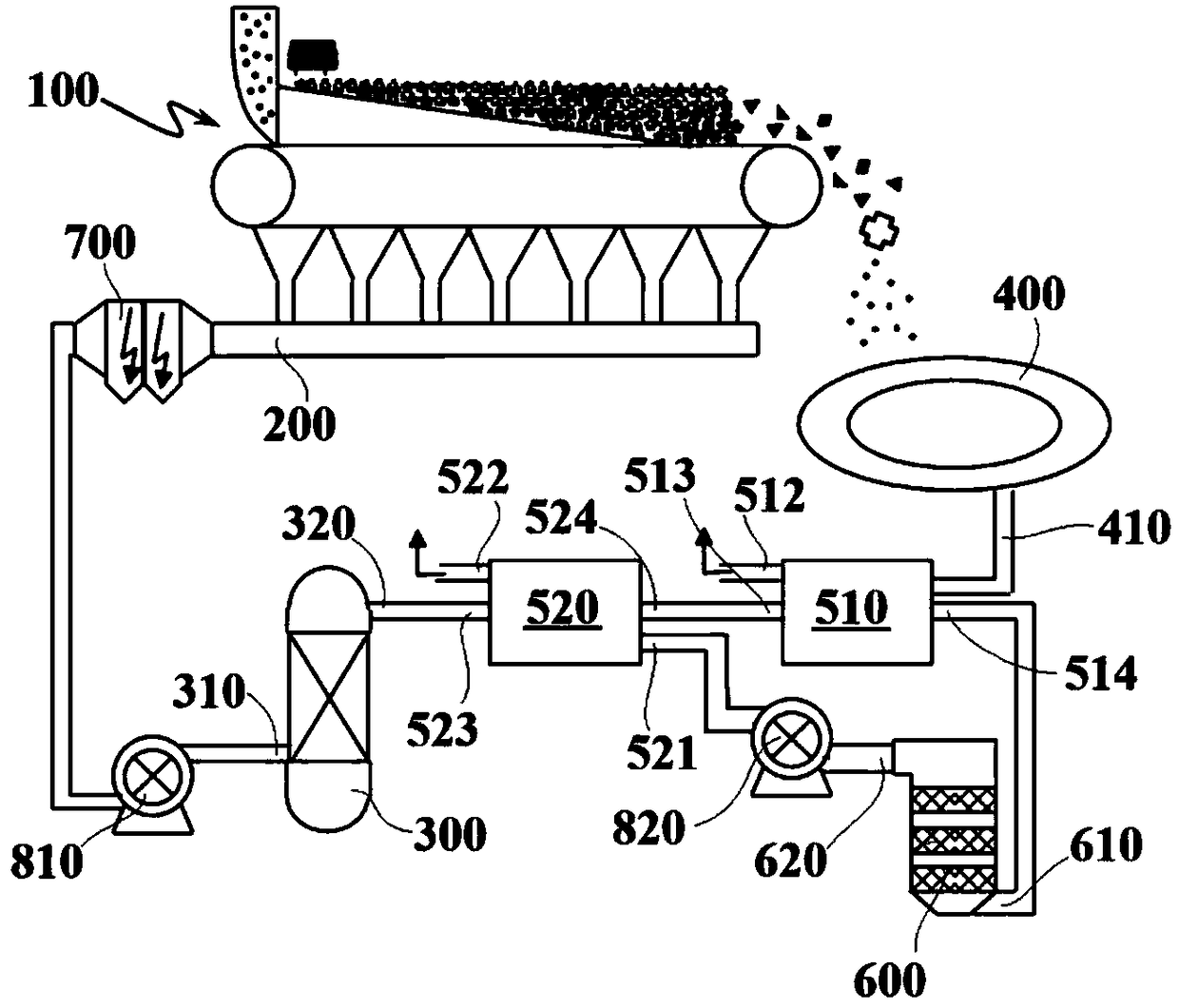

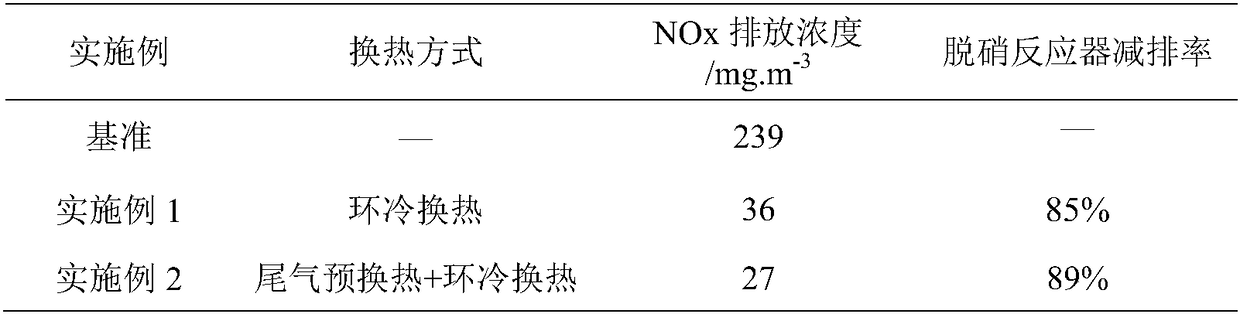

[0039] like figure 1 As shown, an ammonia-SCR combined desulfurization and denitrification system based on this embodiment includes a sintering machine 100, a main flue 200, an ammonia desulfurization tower 300, an annular cooler 400, an annular heat exchanger 510, and a denitrification reactor 600. During the sintering process, the sintering material is sintered on the sintering machine 100 , and the generated sintering flue gas enters the main flue 200 through drafting. The sintered material on the sintering trolley is sintered into sintered ore, and then the sintered ore is crushed by the crushing device and transported to the ring cooler 400 for cooling. The annular cooler 400 is divided into the first annular cooling stage, the second annular cooling stage and the third annular cooling stage along the sinter cooling sequence. The blower at the bottom of the annular cooler 400 cools the sintered ore by blowing air, and the air passes through the sintered ore and takes awa...

Embodiment 2

[0055] In this embodiment, on the basis of Embodiment 1, a tail gas heat exchanger 520 is arranged on the pipeline between the ammonia desulfurization tower 300 and the annular cooling heat exchanger 510, and the denitration outlet 620 of the denitration reactor 600 passes through the pipeline and the tail gas heat exchanger. 520 are connected, and the tail gas passes through the tail gas heat exchanger 520 to exchange heat for the sintering flue gas to raise the temperature.

[0056] The exhaust gas heat exchanger 520 in this embodiment is provided with an exhaust gas heating inlet 521, an exhaust gas heating outlet 522, a first heating inlet 523, and a first heating outlet 524, and the denitrification outlet 620 and the first heating inlet 523 are connected by a pipeline connected, the desulfurized sintering flue gas enters the tail gas heat exchanger 520 from the first heating inlet 523, and the first heating outlet 524 of the tail gas heat exchanger 520 communicates with th...

Embodiment 3

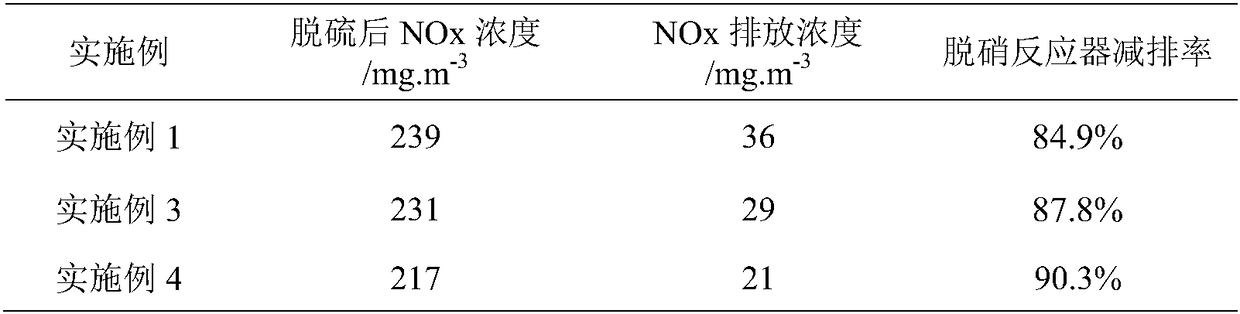

[0065] This embodiment is basically the same as that of Embodiment 1, except that the amount of ammonia sprayed in the ammonia desulfurization tower 300 in this embodiment is 1800m 3 / h, before the sintering flue gas of this embodiment enters the ammonia desulfurization tower 300, the temperature of the flue gas at the desulfurization inlet 310 is 120°C, and the SO 2 The content is 1763mg / Nm 3 , NO x The content is 321mg / Nm 3 ; The sintering flue gas is desulfurized through the ammonia desulfurization tower 300, and the temperature of the sintering flue gas at the desulfurization outlet 320 is 63.5°C, SO 2 The content is 75mg / Nm 3 , NO x The content is 231mg / Nm 3 , the desulfurization rate is 95.7%, and the denitrification rate of ammonia desulfurization tower 300 is 28.0%. And then through the denitrification reactor 600 denitrification, the denitrification outlet 620 NO x Content is 29m 3 / h, the denitration rate of the denitration reactor 600 is 87.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com