Method and device for simultaneous desulphurization and denitration by flue gas-seawater method

A desulfurization, denitrification, seawater technology, applied in separation methods, chemical instruments and methods, climate sustainability, etc., can solve the problems of secondary pollution, high construction and operation costs, complex processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

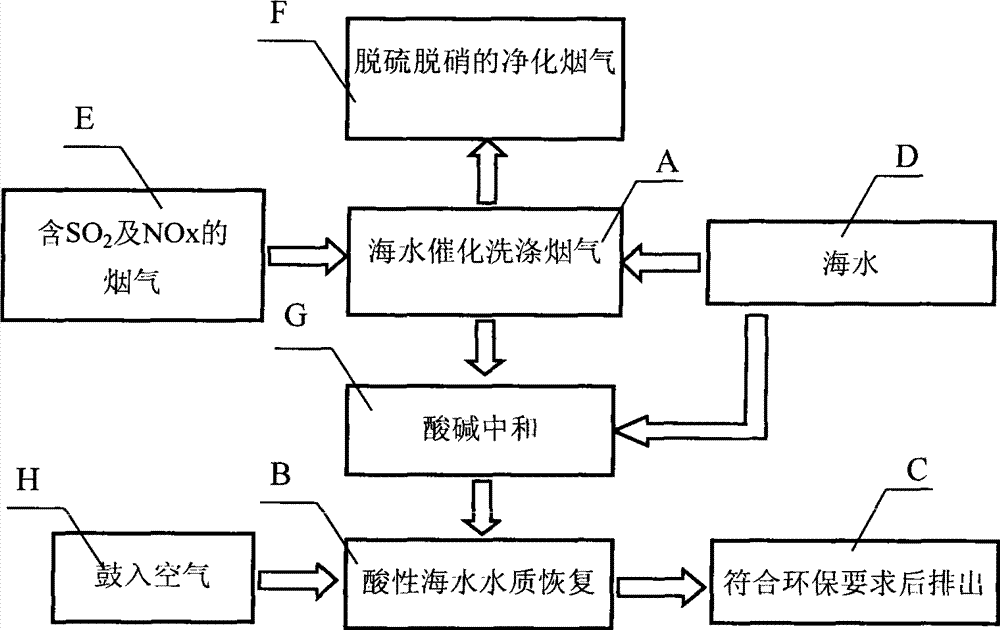

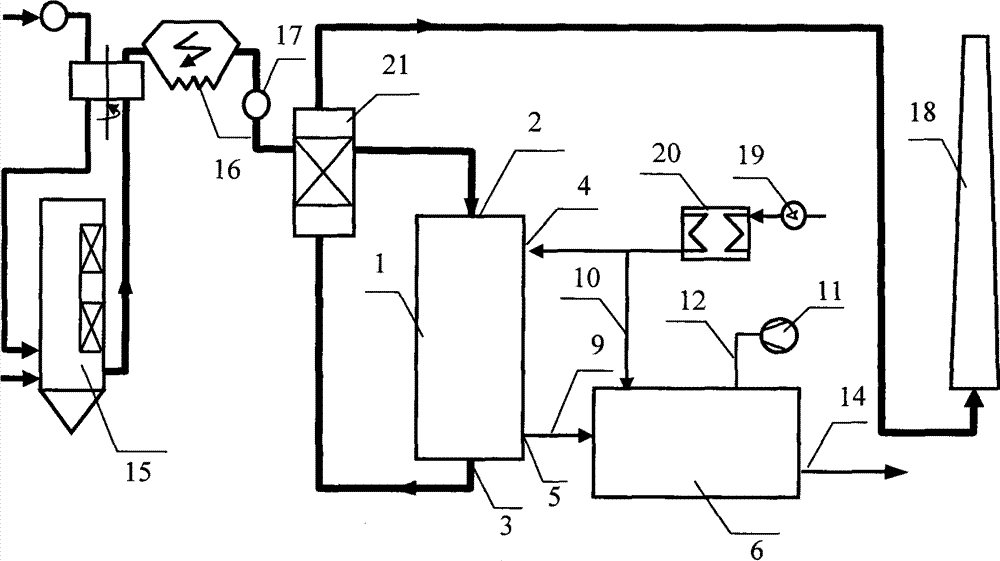

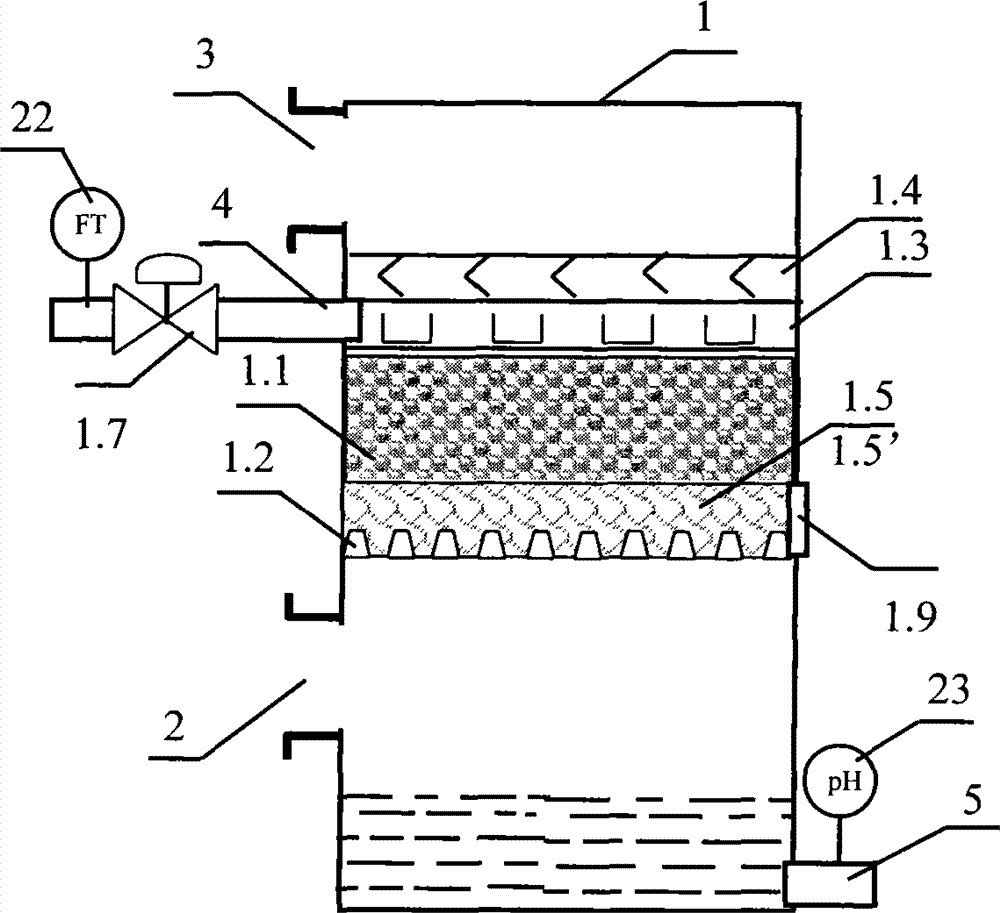

[0050] Such as figure 1 Shown is a schematic diagram of the steps of the simultaneous desulfurization and denitrification method of flue gas and seawater method of the present invention, figure 2 It is the process program of the present invention applied in thermal power plants; the steps of the method for simultaneous desulfurization and denitrification of flue gas by seawater method in this embodiment are: A) seawater catalytic cleaning flue gas: use seawater to contain SO 2 and NOx flue gas for catalytic scrubbing to remove SO in the flue gas 2 and NOx, and then discharge the purified flue gas through simultaneous desulfurization and denitrification and discharge the acidic seawater formed in the washing process; the catalytic washing of the present invention is iron catalytic washing with seawater having or adding a certain amount of iron ions, or / and Make seawater or / and flue gas go through magnetic catalytic washing with an additional magnetic field. As far as this emb...

Embodiment 2

[0063] What is different from the above-mentioned embodiment 1 is that the iron catalytic washing carried out with seawater is to add iron ions through a device that can add iron-containing solution during washing; the main parameters of this embodiment are:

[0064] Flue gas volume 1,100,000Nm 3 / h

[0065] Raw flue gas SO 2 Concentration 1900mg / Nm 3 , NOx concentration 650mg / Nm 3

[0066] Alkaline-acid ratio of washed seawater flue gas 1

[0067] The concentration of iron ion after washing seawater is 106 μg / kg

[0068] Clean flue gas SO 2 76mg / Nm 3 , NOx 380mg / Nm 3

[0069] Sea water quality recovery device drainage pH >6.8

[0070] Drainage COD increment <0.5mg / l

Embodiment 3

[0072] The difference from the above-mentioned embodiments is that the iron catalytic washing is a method in which a metal with lower electrochemical activity than iron is used as a cathode to make part of the iron material in the washing environment become a sacrificial anode to release iron ions; this implementation For example, the main parameters are: flue gas volume 2,100,000Nm 3 / h

[0073] Raw flue gas SO 2 1680mg / Nm 3 , NOx 580mg / Nm 3

[0074] The alkali-acid ratio of the washed seawater flue gas is 200

[0075] Washing seawater iron ion concentration 300μg / kg

[0076] Clean flue gas SO 2 80mg / Nm 3 , NOx 180mg / Nm 3

[0077] Sea water quality recovery device drainage pH >6.8

[0078] Drainage COD increment <4.3mg / l

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com