A multi-pollutant synergistic emission reduction method in the sintering process

A sintering process, pollutant technology, applied in the direction of separation method, gas emission reduction, chemical instruments and methods, etc., can solve the problem of insufficient pollutant emission reduction effect, achieve the effect of inhibiting decomposition and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

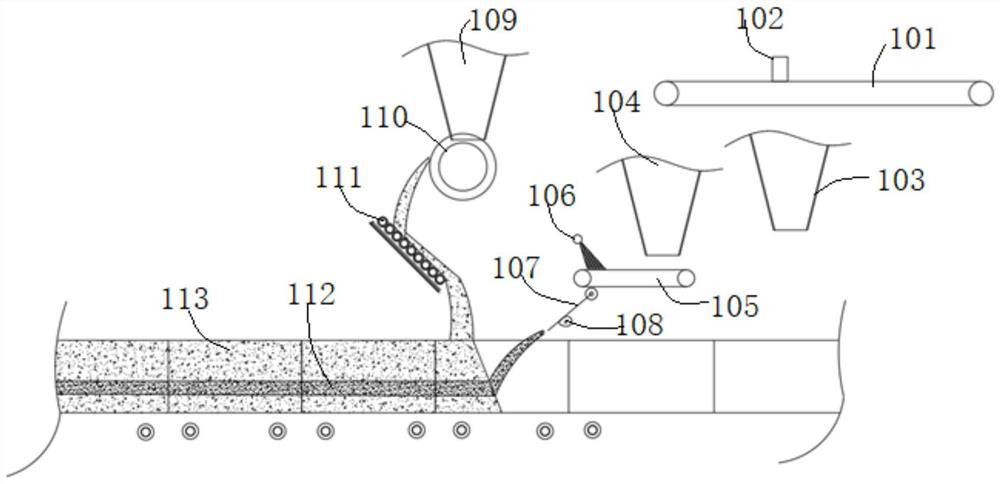

[0036] In this embodiment, a multi-pollutant synergistic emission reduction method in the sintering process uses sintering back powder and emission reducer to distribute in the material layer of the sintering trolley to form a cloth mixed layer 112 inlaid with cloth, and reduces and decomposes NO through sintering back powder The combination of catalysis and emission reducing agent can realize the synergistic emission reduction of multiple pollutants in the sintering process. The emission reducing agent includes urea peroxide solution and polyaluminum chloride solution.

[0037] Specifically, the following steps are included:

[0038] S1. The base laying bin 103 spreads the bottom material on the sintering trolley, and then the mixing bin 109 spreads the mixed material on the sintering trolley to form a trolley cloth sintering material 113;

[0039] S2. The sintered powder return in the powder return chamber 104 is inlaid with the cloth and the mixed material to form a cloth m...

Embodiment 2

[0047] A multi-pollutant synergistic emission reduction method in the sintering process of this embodiment is basically the same as that of Embodiment 1, the difference is that in this embodiment, the bottom layer silo 103 distributes bottom layer material with a thickness of 35 mm on the sintering trolley through a funnel; The height position of the cloth mixing layer 112 is basically maintained at 15 mm below the corresponding position where the over-humidity zone in the sintering process is just eliminated; The spraying total amount of kind solution makes the sintering back powder water content on the powder feeding belt 105 reach 5%, and the cloth total amount of sintering back powder is 10% of the trolley cloth sintering material 113 total amount on the whole sintering trolley.

Embodiment 3

[0049] A multi-pollutant synergistic emission reduction method in the sintering process of this embodiment is basically the same as that of Embodiment 1, the difference is that in this embodiment, the bottom layer silo 103 spreads bottom layer material with a thickness of 45 mm on the sintering trolley through a funnel; The height position of the cloth mixing layer 112 is basically maintained at 20mm below the corresponding position where the over-humidity zone in the sintering process is just eliminated; The spraying total amount of kind solution makes the sintering back powder water content on the powder feeding belt 105 reach 4%, and the cloth total amount of sintering back powder is 8% of the trolley cloth sintering material 113 total amount on the whole sintering trolley.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com