Combined emission-reducing device for multiple pollutants in flue gas caused by iron-ore sintering and use method thereof

A technology for sintering flue gas and combined emission reduction, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of reducing nitrogen oxide emissions and reducing the types of pollutants, and achieve the effect of promoting effective reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

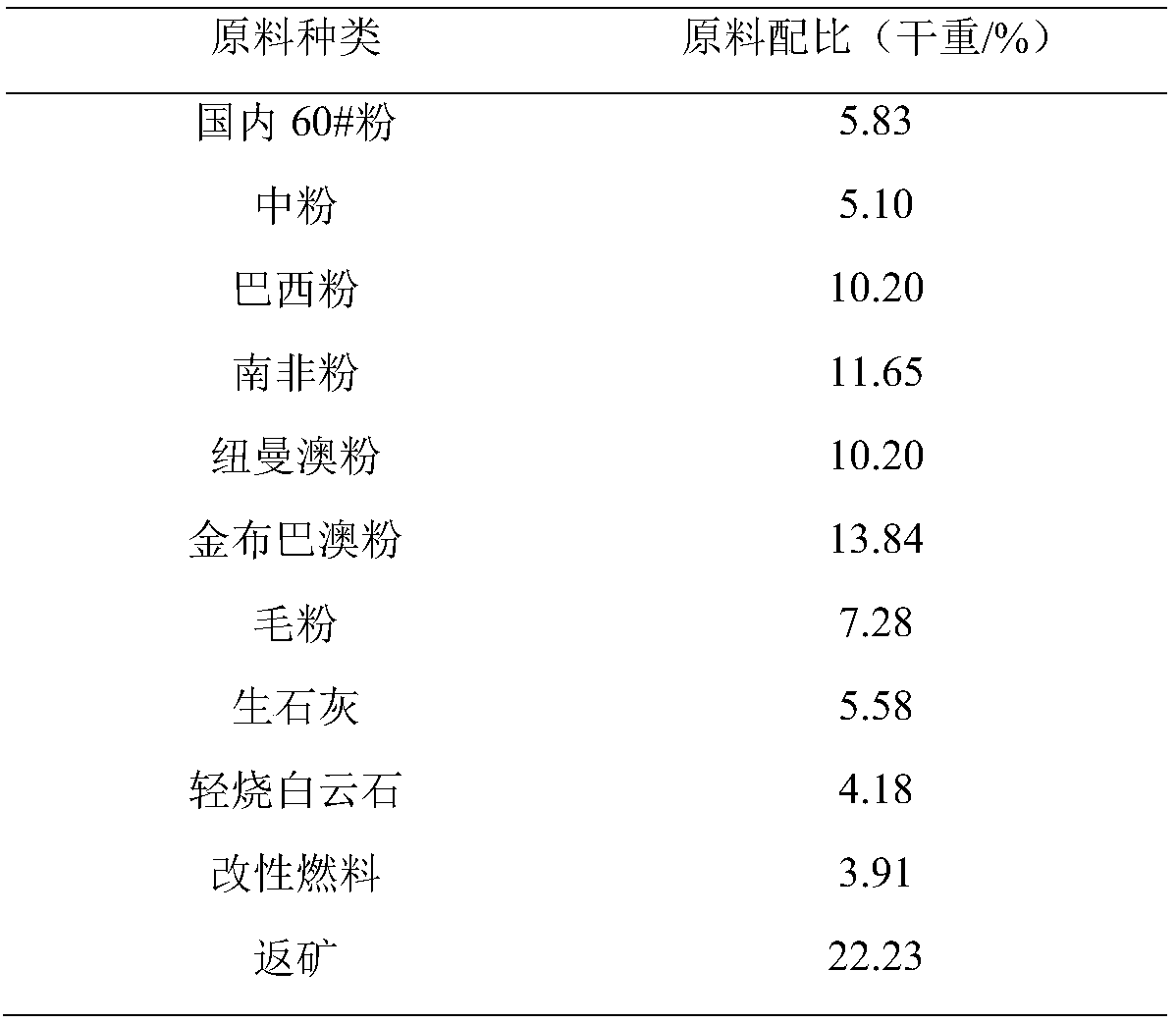

Embodiment 1

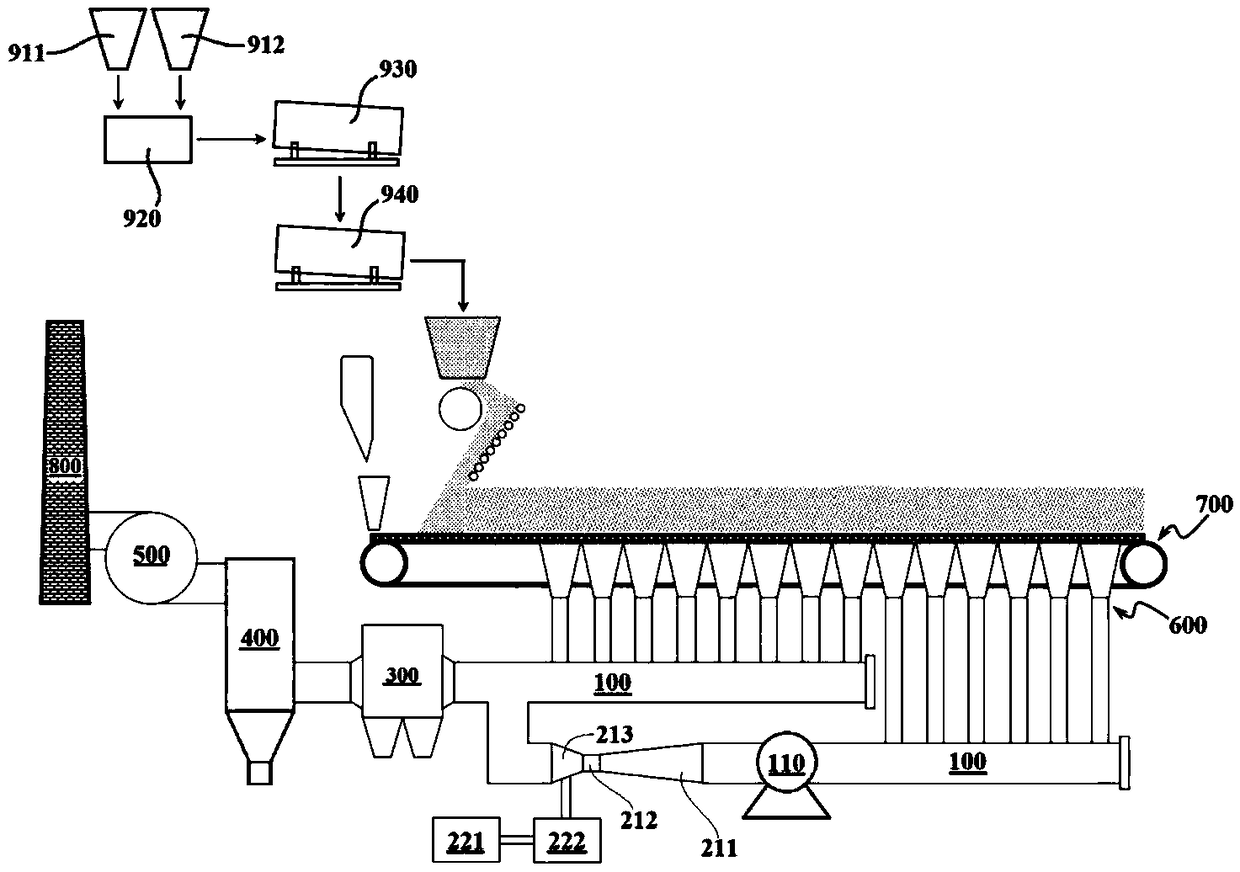

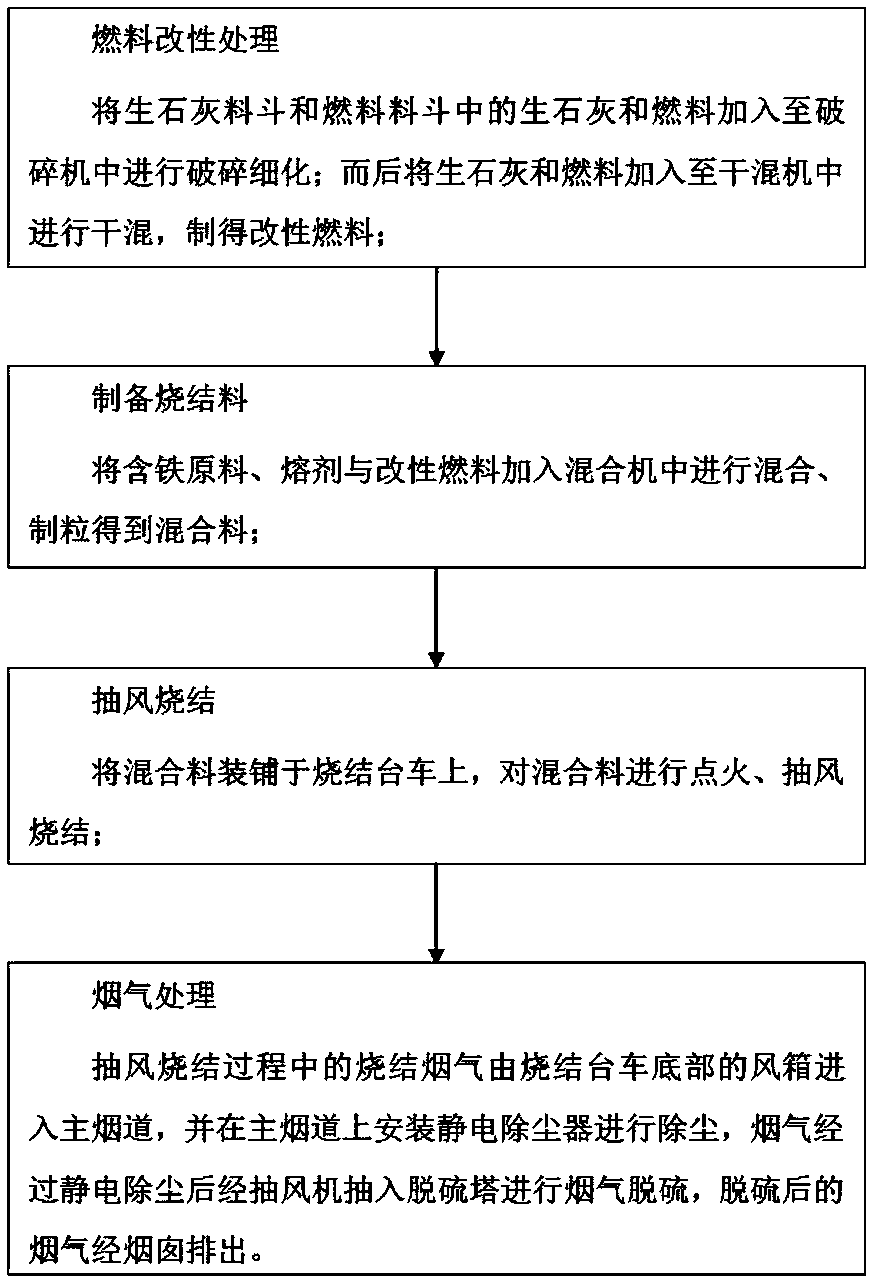

[0044] Such as Figure 1~2 As shown, a combined emission reduction device for multiple pollutants in iron ore sintering flue gas according to the present invention includes a fuel modification unit, a sintering trolley 700 and a flue gas treatment unit. The fuel modification unit includes a hopper, a crusher 920, a dry mixer 930 and a mixer 940; the hopper includes a quicklime hopper 911, and a high-temperature dryer is arranged on the hopper to generate high temperature to dry the quicklime in the hopper, and the quicklime hopper 911 and The discharge port of the fuel hopper 912 is set above the crusher 920; the discharge end of the crusher 920 is connected to the feed end of the dry mixer 930; a vibrating screen is arranged below the crusher 920, and a diameter The sieve hole is 0.3mm-5mm; the discharge end of the dry mixer 930 is set correspondingly to the feed end of the mixer 940, and a dryer is installed in the dry mixer 930 to dry the inner wall of the dry mixer. The d...

Embodiment 2

[0058] The basic content of this embodiment is the same as that of Example 1, except that the mass ratio of the fuel with a particle size of less than 1.0 mm to the fuel with a particle size greater than 1.0 mm in step (1) is: 1 to 1.86, the particle size of the fuel in this embodiment The composition is shown in Table 2, wherein the mass ratio of the fuel with particle size less than 1.0 mm to the fuel with particle size greater than 1.0 mm in this embodiment is 1.

[0059] Put the mixed material on the trolley, ignite the mixed material, ventilate and sinter, and detect the NO in the sintering flue gas in the main sintering flue gas pipeline X content, and recorded as shown in Table 5.

[0060] The particle size composition of the fuel of table 2 embodiment 2

[0061]

Embodiment 3

[0063] The basic content of this embodiment is the same as that of Example 1, except that the mass ratio of the fuel with a particle size of less than 1.0 mm to the fuel with a particle size greater than 1.0 mm in step (1) is: 1 to 1.86, the particle size of the fuel in this embodiment The composition is shown in Table 3, wherein the mass ratio of the fuel with a particle size of less than 1.0 mm to the fuel with a particle size greater than 1.0 mm in this embodiment is 1.5.

[0064] Put the mixed material on the trolley, ignite the mixed material, ventilate and sinter, and detect the NO in the sintering flue gas in the main sintering flue gas pipeline X content, and recorded as shown in Table 5.

[0065] The particle size composition of the fuel of table 3 embodiment 3

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com