Electromagnetic shielding function composite gel with oriented porous structure and preparation method thereof

A porous structure and composite gel technology, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems of not giving full play to the advantages of compounding between components with electromagnetic functions, environmental pollution, etc., and achieve excellent electromagnetic shielding performance and easy process control , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

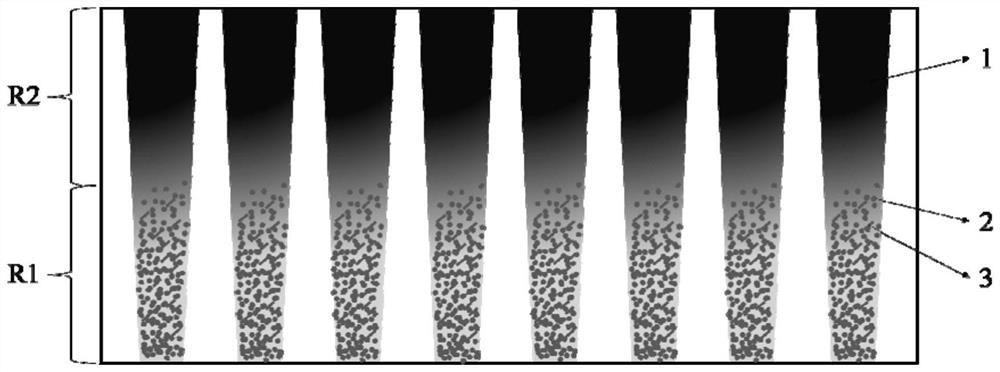

[0031] The preparation method of the above-mentioned electromagnetic shielding functional composite gel with an oriented porous structure adopts solution casting and directional freeze-drying technology to construct an oriented porous structure, which specifically includes the following steps:

[0032] The first step is to dissolve 2.0g of polyvinyl alcohol particles in 20.0mL of deionized water at 95°C using high-speed mechanical stirring to prepare a polyvinyl alcohol aqueous solution, add nickel powder in different proportions to the above solution, and stir for 8 hours to obtain a solution R1;

[0033] In the second step, 2.0 g of polyvinyl alcohol particles were dissolved in 20.0 mL of 1 wt.% poly(3,4-ethylenedioxythiophene): polyethylene sulfonic acid aqueous solution at 95° C. using high-speed mechanical stirring, Stir for 2h to obtain solution R2;

[0034] The third step is to cast the solution R1 in a horizontal polytetrafluoroethylene mold after vacuum defoaming, an...

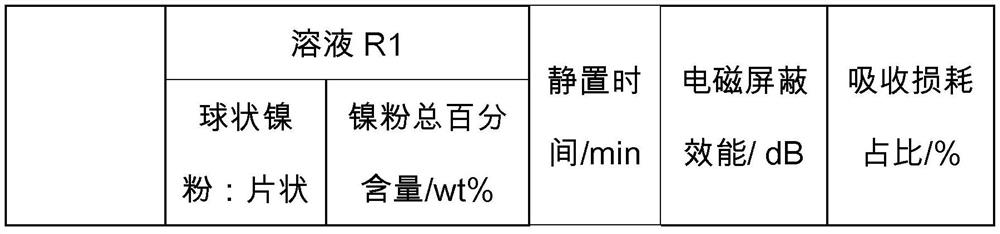

Embodiment 1

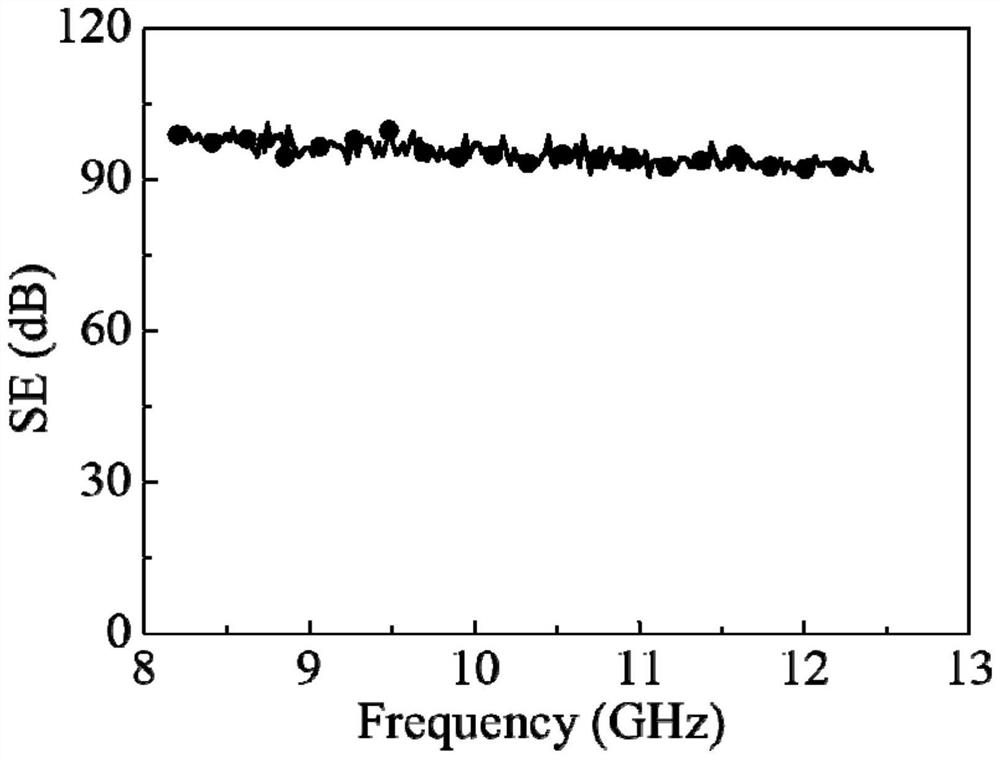

[0041] (1) Using a 50ml three-neck flask, add 20.0ml of deionized water, weigh 2.0g of polyvinyl alcohol and transfer it to the flask. At 95°C, the polyvinyl alcohol was completely dissolved by mechanical stirring at a speed of 700r / min. Weigh 0.2g of spherical nickel powder and 0.2g of flake nickel powder, transfer the mixed nickel powder to the polyvinyl alcohol solution under the conditions of maintaining 95°C and 700r / min, stir for 8 hours to completely disperse the nickel powder to obtain solution R1.

[0042] (2) Using a 50ml three-necked flask, add 20.0ml of 1wt.% poly(3,4-ethylenedioxythiophene): an aqueous solution of polyethylene sulfonic acid, weigh 2.0g of polyvinyl alcohol and transfer it to the flask . Dissolve the polyvinyl alcohol at 95°C with mechanical stirring at a speed of 700r / min. Stir for 2 h to completely dissolve the polyvinyl alcohol to obtain solution R2.

[0043] (3) After degassing the solution R1, drool in a horizontally placed polytetrafluoroe...

Embodiment 2

[0045] The method is as in Example 1, in (1), 0.27g of spherical nickel powder and 0.13g of flake nickel powder are weighed. The electromagnetic shielding effectiveness of the composite gel can reach 44.3dB. Absorption losses account for 85.5% of the total shielding effectiveness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com