Device for cutting round glass

A circular and glass technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of insufficient cutting precision of glass plates and difficulties in cutting circular glass plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

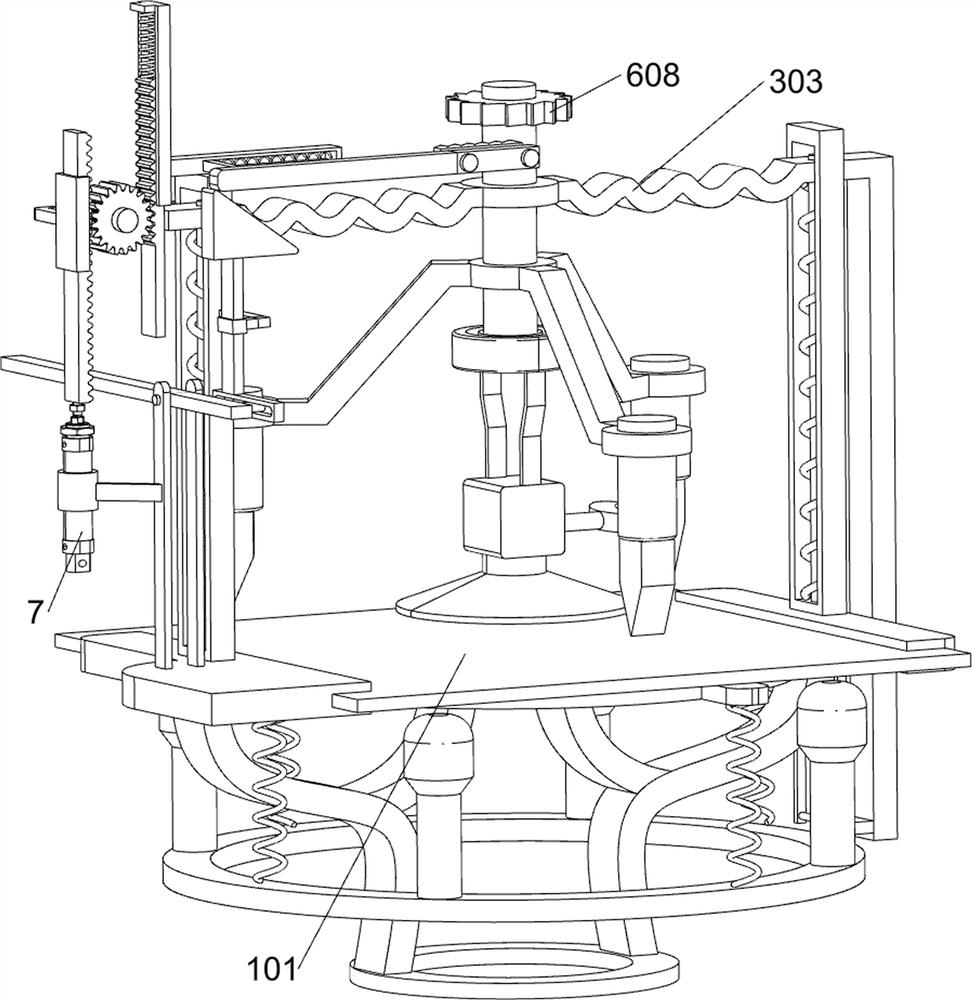

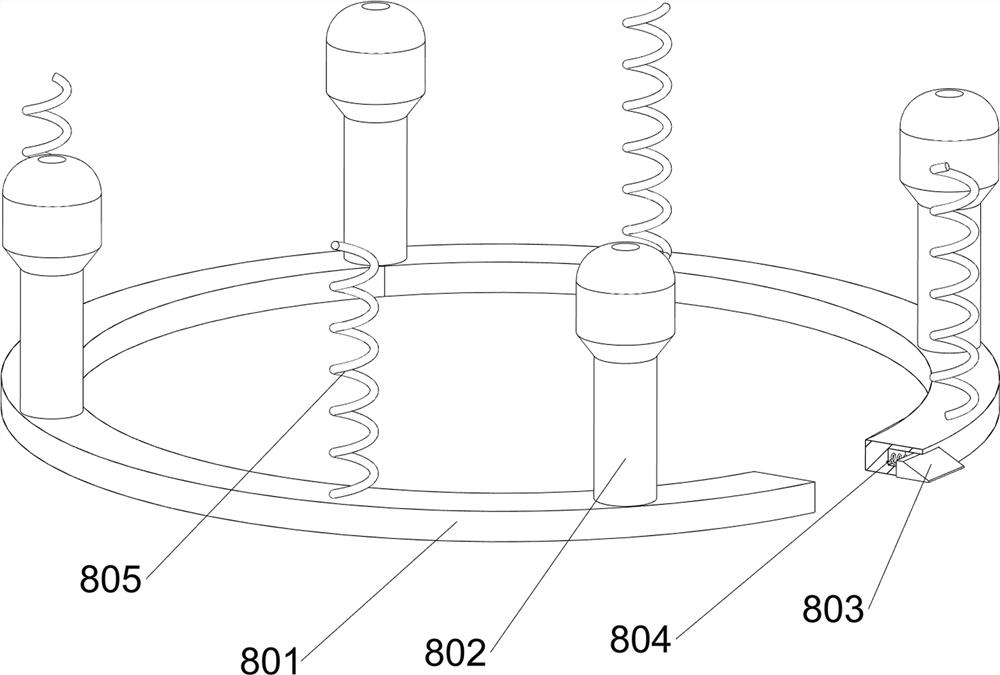

[0027] A device for cutting round glass such as figure 1 and figure 2 As shown, it includes an annular base 1, a glass plate 101, a placement assembly 2, a guide assembly 3 and a cutting assembly 4. The top of the annular base 1 is provided with a placement assembly 2, and the top of the placement assembly 2 is placed with a glass plate 101. Guide assemblies 3 are provided, and cutting assemblies 4 are arranged between the guide assemblies 3 .

[0028] When people need to cut the glass plate 101 into a circle, this device can be used. First, the glass plate 101 is placed on the placement assembly 2, and the guide assembly 3 is manually pressed, and the guide assembly 3 drives the cutting assembly 4 to move downward, thereby When the cutting assembly 4 is rotated, the glass plate 101 is cut in a circle. After cutting, put on gloves and use a tool to gently knock the excess glass plate 101 downwards. The excess glass will fall, and people can get a circle. shaped glass plate ...

Embodiment 2

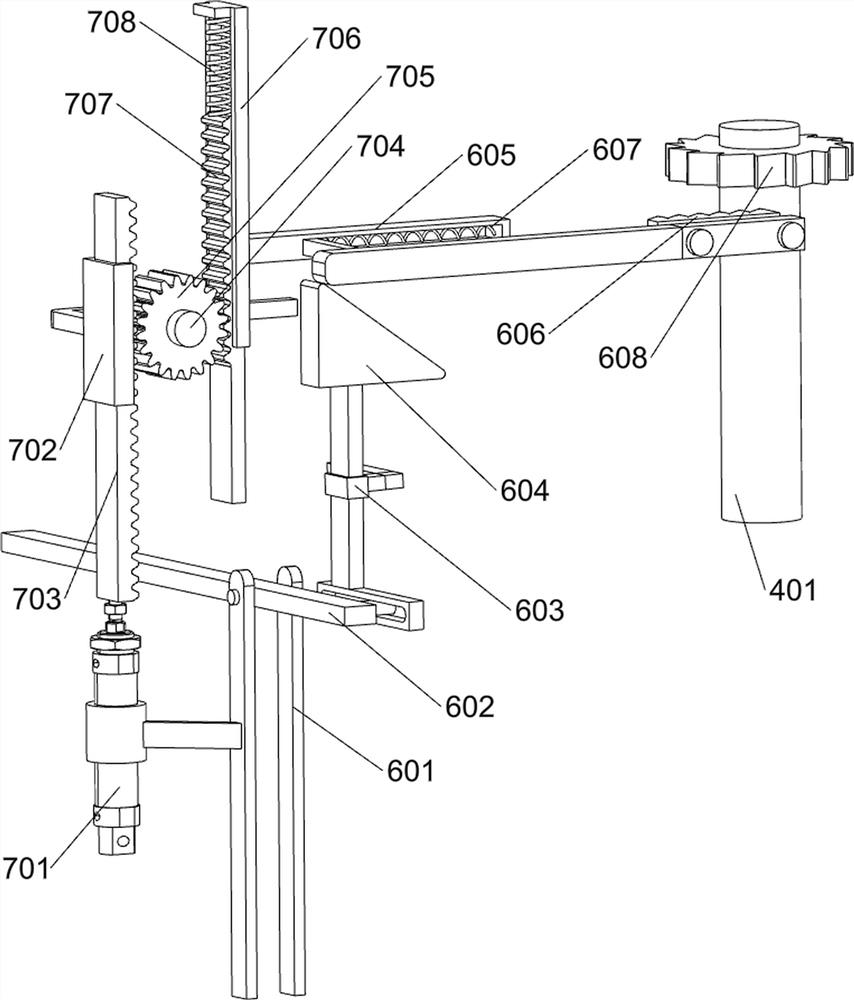

[0036]On the basis of Example 1, such as image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a pressing assembly 5 is also included. The pressing assembly 5 includes a bearing 501, a suction cup 502, a buckle 503, a second spring 504 and a handle 505. The bottom of the first rotating shaft 401 is provided with a bearing 501, and the bottom of the bearing 501 is provided with a Fixed block, the sliding type in the fixed block is provided with a handle 505, the bottom of the fixed block is connected with a suction cup 502, the suction cup 502 cooperates with the handle 505, the sliding type in the rear side of the fixed block is provided with a buckle 503, and a buckle 503 is provided between the buckle 503 and the fixed block. There is a second spring 504 , and the buckle 503 cooperates with the handle 505 .

[0037] When the first rotating shaft 401 moves downward, it drives the bearing 501 to move downward, so that the bearing 501 drives the suction cup 502 to move do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com