Processing method of piezoelectric composite material

A technology of piezoelectric composite materials and piezoelectric materials, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc. It can solve the problems of failure of material performance to meet expectations, piezoelectric phase collapse, high scrap rate, etc., meet performance requirements and reduce the difficulty of manufacturing process, reduce cumulative errors, and improve processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

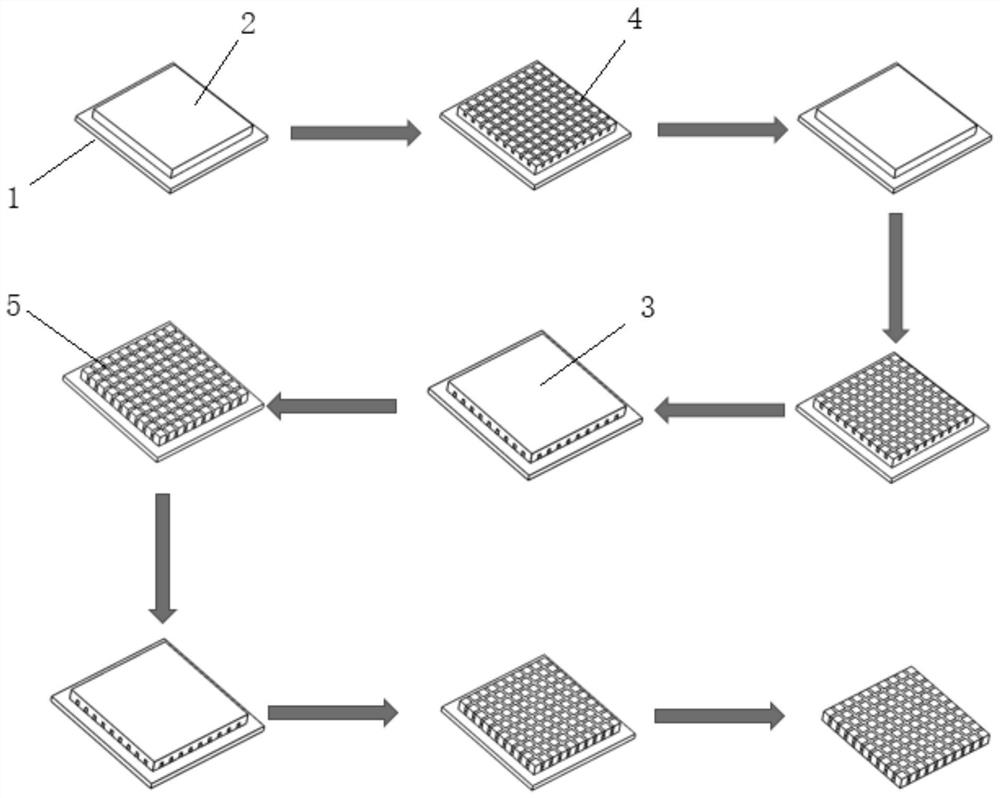

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

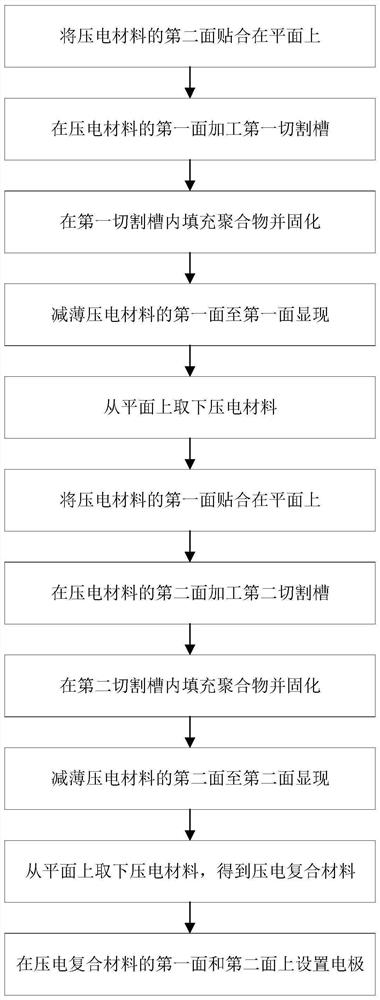

[0047] Such as figure 1 Shown is a flow chart of an embodiment of the processing method of the piezoelectric composite material of the present invention. The processing method of the piezoelectric composite material of the present embodiment comprises the following steps:

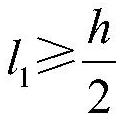

[0048] 1) Lay the second surface of the piezoelectric material on the plane; the length and width of the piezoelectric material in this embodiment are ≥30*30mm, and the length and width of the first and second surfaces are respectively the length and width of the piezoelectric material , that is, the first surface and the second surface are respectively two parallel surfaces opposite to the piezoelectric mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com