a co 2 Preparation method of electrode catalyst for electrochemical reduction

An electrochemical and catalyst technology, applied in the field of electrode catalyst preparation, can solve the problem of less catalyst stability, and achieve the effects of many surface active sites, large electrochemical reaction area, and stable catalyst structure.

Active Publication Date: 2022-06-03

DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In the improvement strategy of alloying, the alloying of Cu with Au, Pd, Sn, Zn and other metals has been reported, and these alloys without exception have improved the selectivity to CO, but the catalyst stability There are very few reports so far

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

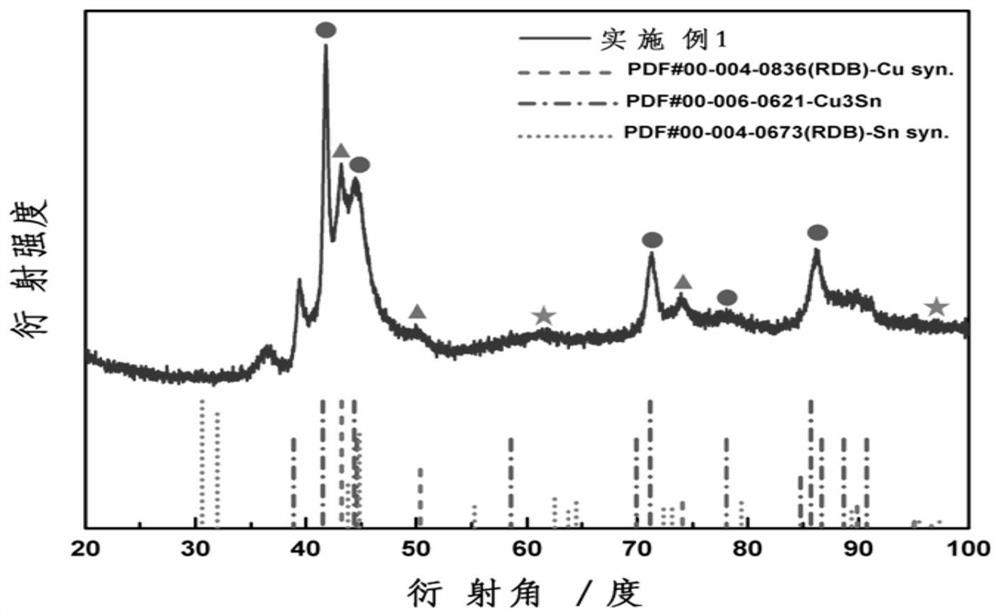

The present invention provides a CO 2 A method for preparing an electrode catalyst for electrochemical reduction, in a soluble strongly acidic mixed solution containing soluble Cu salt and a second alloy element, at room temperature and in an inert atmosphere, using a thin sheet-shaped conductive material as a substrate, using a rapid current deposition process Precipitated hydrogen bubbles are used as templates to obtain. Catalysts prepared by this method are sensitive to CO 2 The electrochemical reduction has excellent electrocatalytic activity and structural stability. The faradaic efficiency of CO is greater than 90%, and the optimum is 98%. The continuous and stable operation exceeds 30h, and the decrease in faradaic efficiency of effective products is less than 5%.

Description

a CO 2 Preparation method of electrode catalyst for electrochemical reduction technical field The invention belongs to the technical field of electrochemical reduction of carbon dioxide, particularly a kind of preparation method of electrode catalyst Law. Background technique Electrochemical reduction of CO 2 (ERC) technology is the use of electrical energy to convert CO 2 Reduction to the target product to achieve CO 2 Convert and Effective A technology that utilizes and recycles carbon. At present, the main factors of slow development of ERC technology include: (1) high reaction overpotential; (2) low catalytic activity and reaction The reaction rate is slow; (3) the target product selectivity is poor; (4) the electrode stability is low. In the ERC reaction with aqueous solution as the supporting electrolyte In the reaction system, plate (such as sheet, foil and bulk) metal is usually used to catalyze the electrode reaction process. Among them, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C25B11/089C25B11/03C25B3/26C25B3/07C25B1/02C25B1/23C25D3/58C25D7/00

CPCC25B11/03C25B1/00C25D3/58C25D7/00Y02E60/36

Inventor 邱艳玲李先锋郑琼姚鹏飞张华民

Owner DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com