Recombinant saccharomyces cerevisiae and application thereof in production of conjugated linoleic acid

A technology of recombinant Saccharomyces cerevisiae and conjugated linoleic acid, which is applied in the fields of genetic engineering and microbial engineering, can solve the problems that CLA is not suitable for industrial production, it is difficult to separate, and the chemical synthesis method cannot really achieve high-purity CLA monomer. Realize the effect of industrialized cultivation and easy industrialized cultivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Example 1: Screening of genes encoding linoleic acid isomerase

[0070] Specific steps are as follows:

[0071] The transcriptomics data of Bifidobacterium breve (Bifidobacterium breve) CGMCCNo.11828 (recorded in the patent application text with publication number CN105925514A) under linoleic acid stress was collected through the PacBio sequencing platform, and the sampling time points were 3h, 8h, respectively. 15h.

[0072] After bioinformatics analysis, it was found that in Bifidobacterium breve (Bifidobacterium breve) CGMCCNo.11828, there were 8 genes with increased gene transcription levels at the three time points, and these 8 genes were respectively annotated as coding " Unknown protein 1", "mellibiose carrier protein", "ribokinase", linoleate hydratase, "unknown protein 2", "transcriptional regulatory protein", "ribose-binding ABC channel protein 1" and "ribose-binding ABC channel Protein 2" gene, among them, the transcription level of the gene encoding "unkno...

Embodiment 2

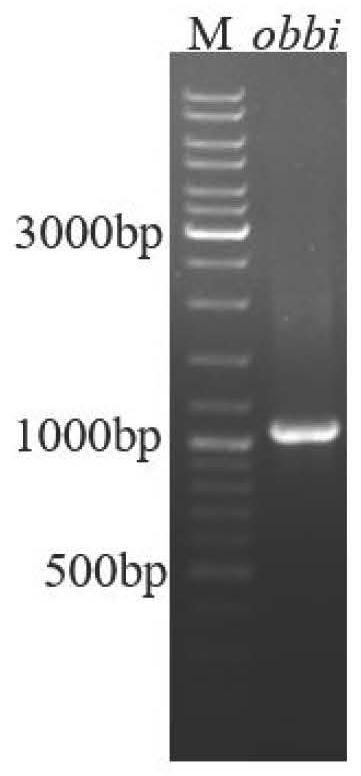

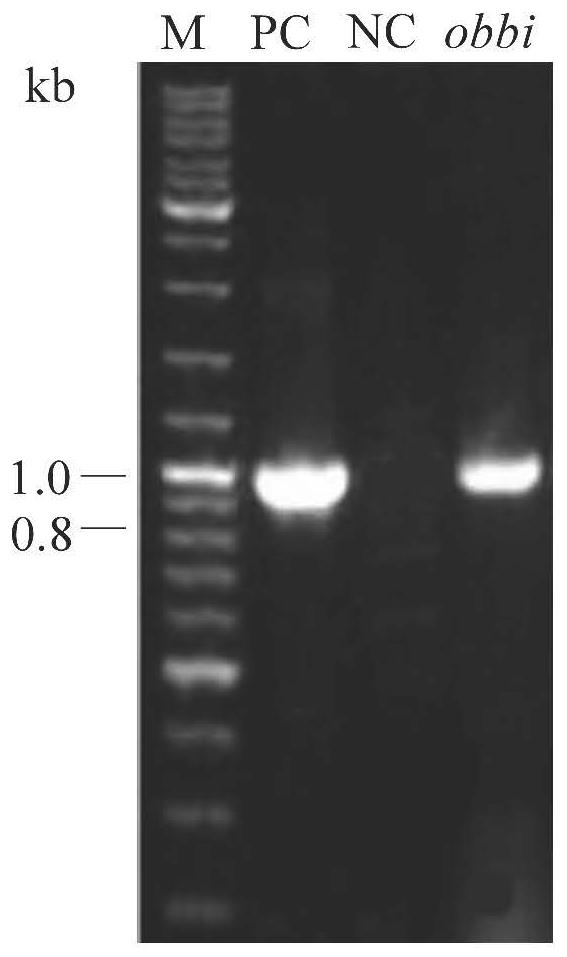

[0073] Example 2: Cloning of the gene encoding linoleic acid isomerase

[0074] Specific steps are as follows:

[0075] Pick the bacteria solution of Bifidobacterium breve (Bifidobacterium breve) CGMCC No.11828 from the bacteria preservation tube, streak it on the MRS solid medium, cultivate it in a constant temperature anaerobic workstation at 37°C for 48 hours, and obtain a single colony; pick a single colony for inoculation In the MRS liquid medium, continue to stand still for 24 hours in a constant temperature anaerobic workstation at 37°C, and activate continuously for 3 generations to obtain an activated bacterial liquid; inoculate the activated bacterial liquid at an inoculum of 1% (v / v) Inoculate into MRS liquid medium, culture in a constant temperature anaerobic workstation at 37°C for 24 hours to obtain a bacterial suspension; centrifuge the obtained bacterial suspension at 25°C and 12000g for 10 minutes to obtain wet bacterial cells; use bacterial genomic DNA The e...

Embodiment 3

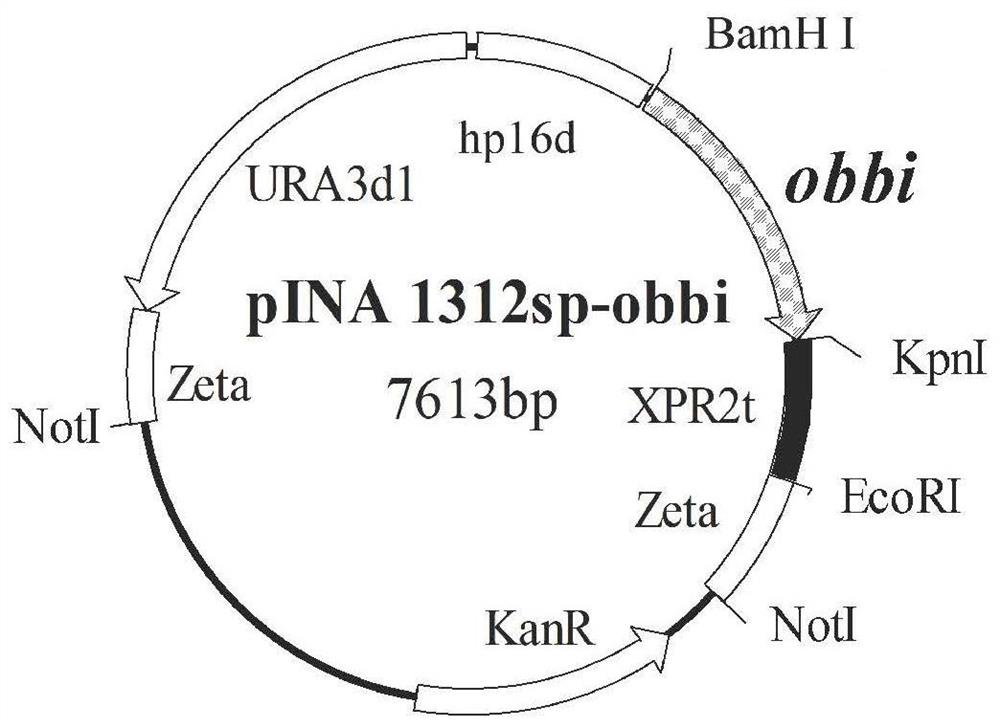

[0080] Example 3: Optimization of the gene encoding linoleic acid isomerase

[0081] Specific steps are as follows:

[0082] According to the codon preference of yeast, the bbi gene was optimized using Genscript OptimumGene TM software, and the optimized gene was named obbi gene. The obbi gene was synthesized by Nanjing GenScript Biotechnology Co., Ltd. and cloned into the vector pUC57 , to obtain the recombinant plasmid pUC57-obbi; wherein, the nucleotide sequence of the bbi gene is shown in SEQ ID No.2, and the nucleotide sequence of the obbi gene is shown in SEQ ID No.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com