High-speed iron putty polyester resin material, main agent and preparation method thereof, high-speed iron putty and application method thereof

A technology of polyester resin and putty, which is applied in the field of high-speed rail putty and its application, high-speed rail putty polyester resin material, which can solve the problem of large area of putty scraping and polishing, small pinholes that cannot be easily closed, and affect the appearance of the whole vehicle, etc. problems, to achieve excellent flexibility, reduce adsorption, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

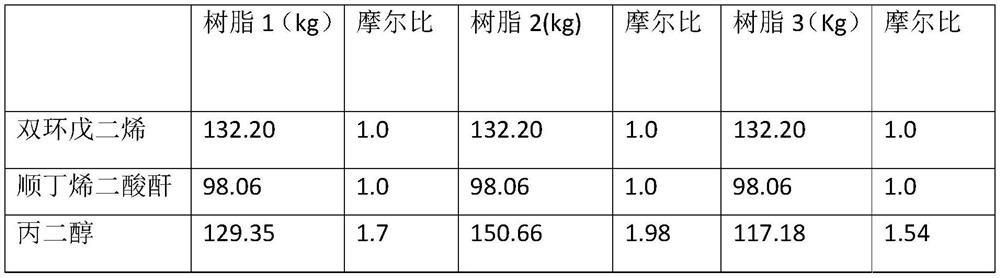

[0057] The embodiment of the present invention provides a preparation method of a high iron putty polyester resin material, comprising:

[0058] reacting dicyclopentadiene with maleic anhydride to obtain a dicyclopentadiene-maleic anhydride adduct containing double bonds and carboxyl groups;

[0059] The primary unsaturated polyester resin is prepared by polycondensation of dicyclopentadiene-maleic anhydride adduct, dibasic acid and its derivative monomer and dihydric alcohol monomer, dibasic acid and its derivative monomer The body includes at least one of dibasic acid monomer and dibasic acid anhydride monomer, and the dibasic alcohol monomer contains 10-30% of its molar weight of ether bond-containing glycol monomer;

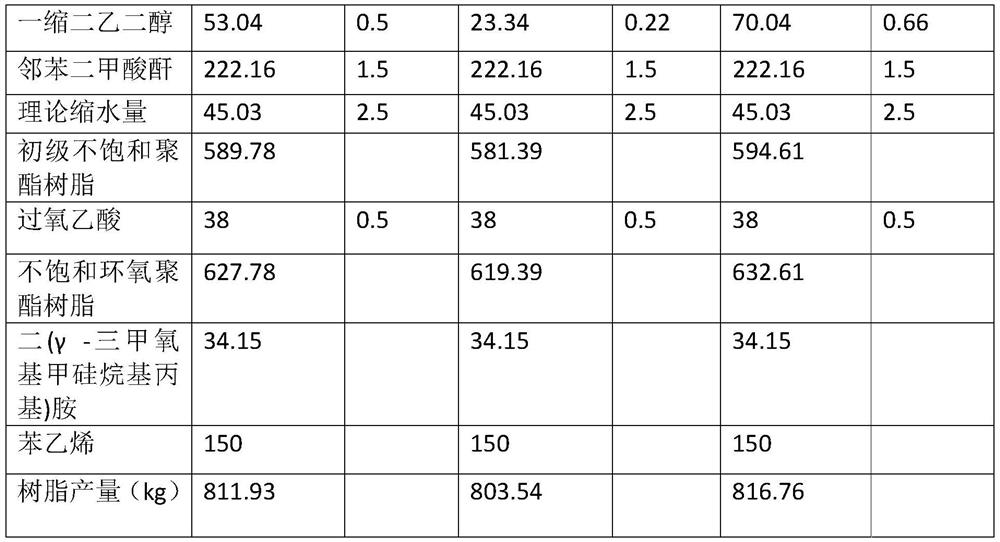

[0060] Oxidizing the dicyclopentadiene group of the primary unsaturated polyester resin into an epoxy group to obtain an unsaturated epoxy polyester resin;

[0061] The unsaturated epoxy polyester resin is modified with a secondary amino silane coupling agen...

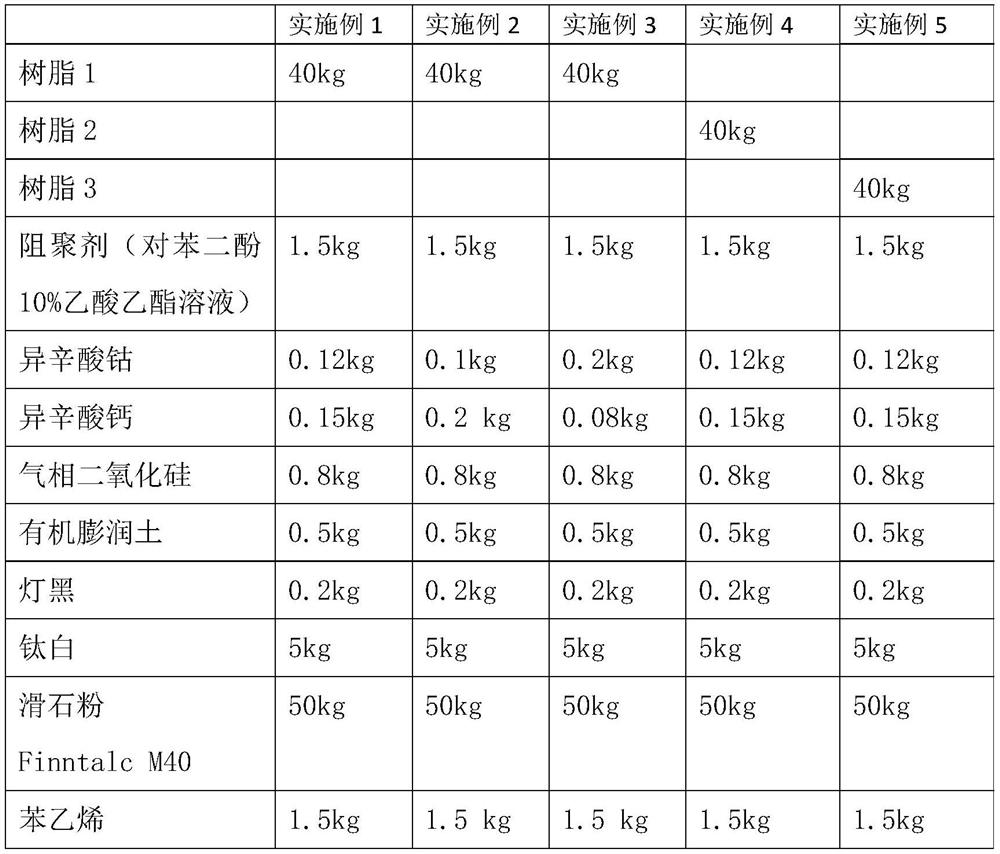

Embodiment 1

[0113] The present embodiment provides the preparation method of high iron putty polyester resin, specifically:

[0114] Dicyclopentadiene and maleic anhydride were first added to the reaction kettle, the temperature was raised to 135° C., and the reaction was carried out for 2 hours. Then add propylene glycol, diethylene glycol, and phthalic anhydride, and stir for about 20 minutes until the mixture is uniform. The temperature was raised to 150°C within 1 hour, and then increased to 200°C at a rate of 10°C per hour. When the acid value is less than 60mg / g, the temperature is lowered to 180°C, and vacuum is applied. When the acid value decreased to 20 mg / g, it was cooled to obtain a primary unsaturated polyester resin.

[0115] The resulting primary unsaturated polyester resin was dissolved in dichloromethane and heated to 40°C. Peracetic acid was added dropwise to the resin under stirring, and the temperature was maintained to react for 3 hours. After the reaction is comp...

Embodiment 2

[0121] This example is basically the same as Example 1, except that the amount of cobalt isooctanoate is 0.1kg (accounting for 0.25% of the mass of the flexible unsaturated polyester resin in the high iron putty polyester resin material), the mass of calcium isooctanoate is 0.1kg It is 0.2kg (accounting for 0.50% of the mass of the flexible unsaturated polyester resin in the resin material).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com