Waterproof and moisture-permeable waterborne polyurethane resin as well as preparation method and application thereof

A water-based polyurethane, waterproof and moisture-permeable technology, applied in textiles and papermaking, etc., can solve the problems of low solid content of water-based polyurethane dispersion, increase process complexity, increase cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

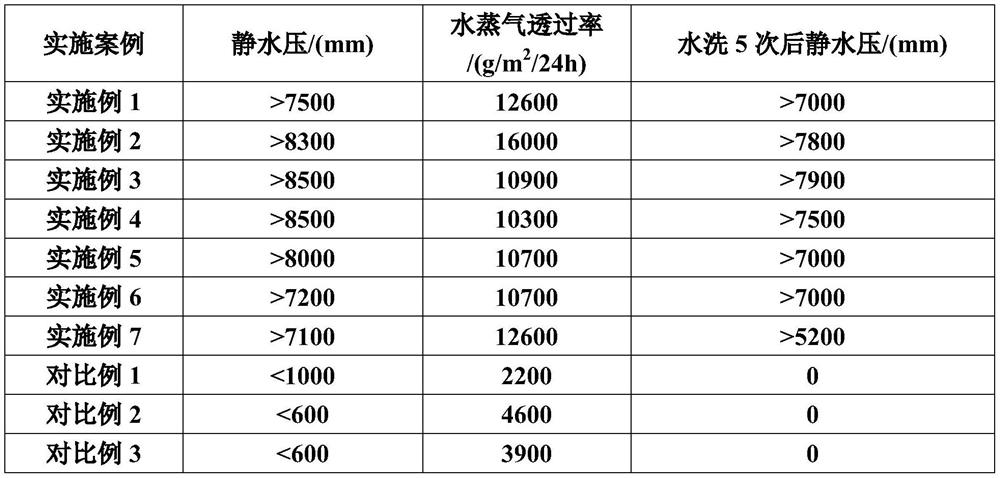

Examples

Embodiment 1

[0081] 500.00 grams of HMS-295R, 26.00 grams F3156D, 14.00 grams of DEG and 4.00 grams of DMPA were heated to 60°C and stirred evenly, then added 97.00 grams IPDI, finally add 32.06 g of acetone and 0.20 g of 8108 catalyst, raise the temperature to 75°C and react for 4 hours to form a prepolymer with isocyanate groups at the end. After adding 896.50 g of water and mixing well, a solution of 5.50 g of EDA, 3.20 g of DEA with 0.80 g of APBA and 47.50 g of water was metered in. After stirring for 20 minutes, an aqueous polyurethane resin solution was obtained.

Embodiment 2

[0083] 360.00 grams of HMS-295R, 64.00 grams Heat F3156D, 29.00 grams of DEG and 26.00 grams of DMPA to 60°C and stir to mix well, then add 160.00 grams IPDI, finally add 31.96 g of acetone and 0.16 g of 8108 catalyst, raise the temperature to 75°C and react for 4 hours to form a prepolymer with isocyanate groups at the end. After adding 893.60 g of water and mixing well, a solution of 5.50 g of EDA, 3.00 g of DEA with 1.00 g of APBA and 47.50 g of water was metered in. After stirring for 20 minutes, an aqueous polyurethane resin solution was obtained.

Embodiment 3

[0085] 470.00 grams of HMS-295R, 40.00 grams Heat F3156D, 12.50 grams of DEG and 11.00 grams of DMPA to 60°C and stir to mix well, then add 105.00 grams IPDI, finally add 31.93 g of acetone and 0.19 g of 8108 catalyst, raise the temperature to 75°C and react for 4 hours to form a prepolymer with isocyanate groups at the end. After adding 895.30 g of water and mixing well, a solution of 5.50 g of EDA, 2.30 g of DEA with 1.00 g of APBA and 44.00 g of water was metered in. After stirring for 20 minutes, an aqueous polyurethane resin solution was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com