Milling cutter machining device and using method thereof

A processing device and milling cutter technology, applied in heating devices, milling cutters, grinding drive devices, etc., can solve the problems of operator injury, debris splashing, affecting the normal operation of the device, etc., to avoid injury and increase friction. , Improve the effect of grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

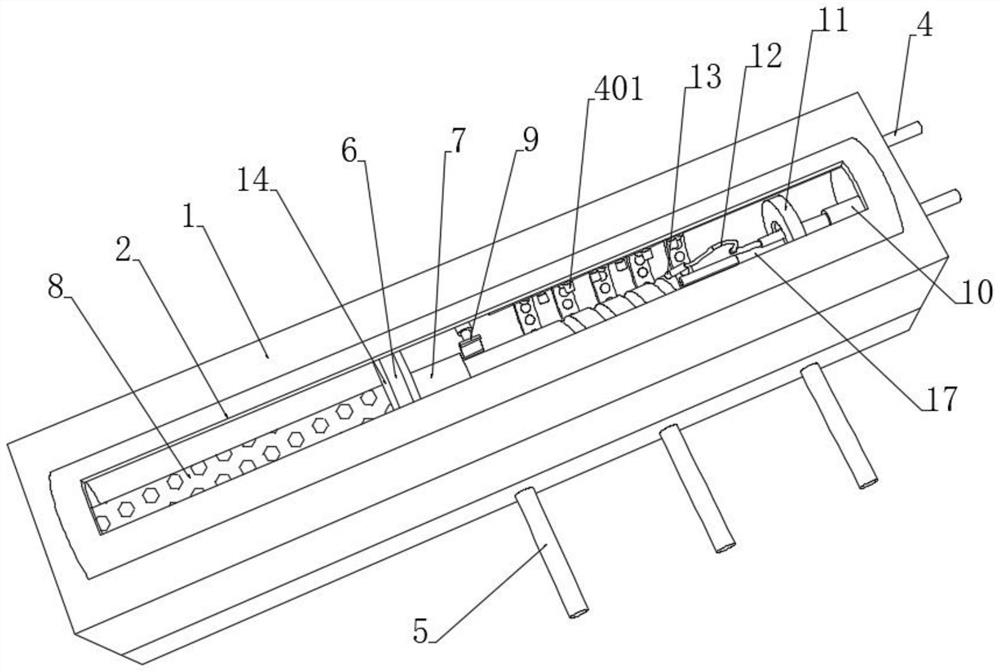

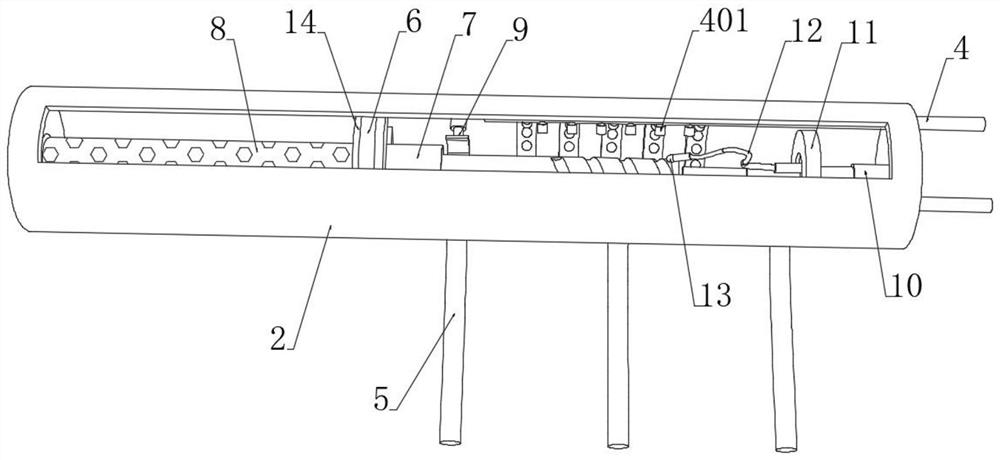

[0045] see Figure 1-3 , a milling cutter processing device, including an embedded seat 1 and a processing roller 2 fixedly embedded in the embedded seat 1, a processing cavity is opened inside the processing roller 2, and an arc is installed on the top of the processing roller 2 to rotate. shaped sealing cover 201, the inside of the processing chamber is embedded with a partition 6, the partition 6 divides the inside of the processing chamber into a drying chamber and a cooling and grinding chamber, the upper and lower ends of the partition 6 are all embedded with a semiconductor refrigeration chip 14, The middle part of the board 6 is provided with a positioning column 7, one end of the positioning column 7 penetrates into the drying chamber and is fixedly connected with a drying column 8, and the other end of the drying column 8 is against the inner wall of the drying chamber. The left and right sides of 7 are provided with fixtures 9 for clamping the milling cutter;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com