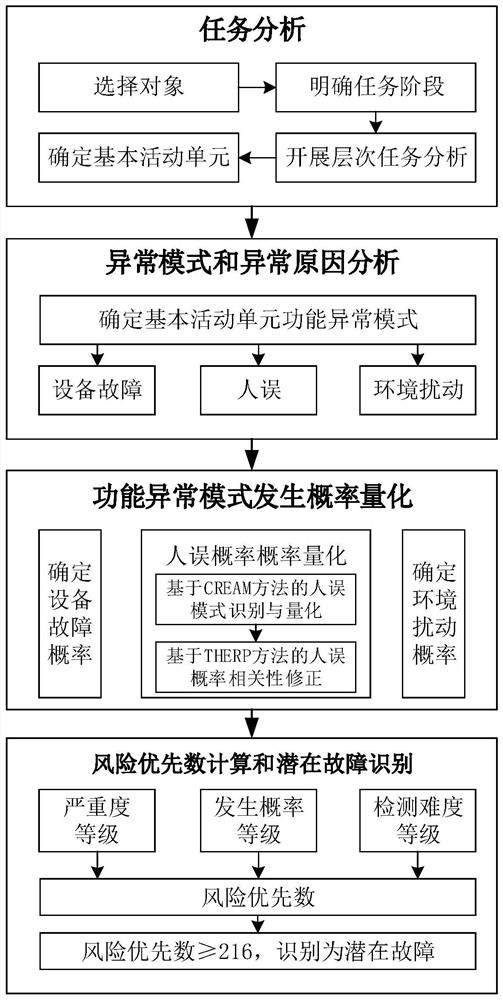

Potential fault analysis method based on PFMEA and HRA methods

A fault analysis method and potential technology, applied in the direction of program control, reduction of greenhouse gases, instruments, etc., can solve problems that are difficult to quantify, achieve broad application value, scientific analysis method, and solve the effect of man-machine separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

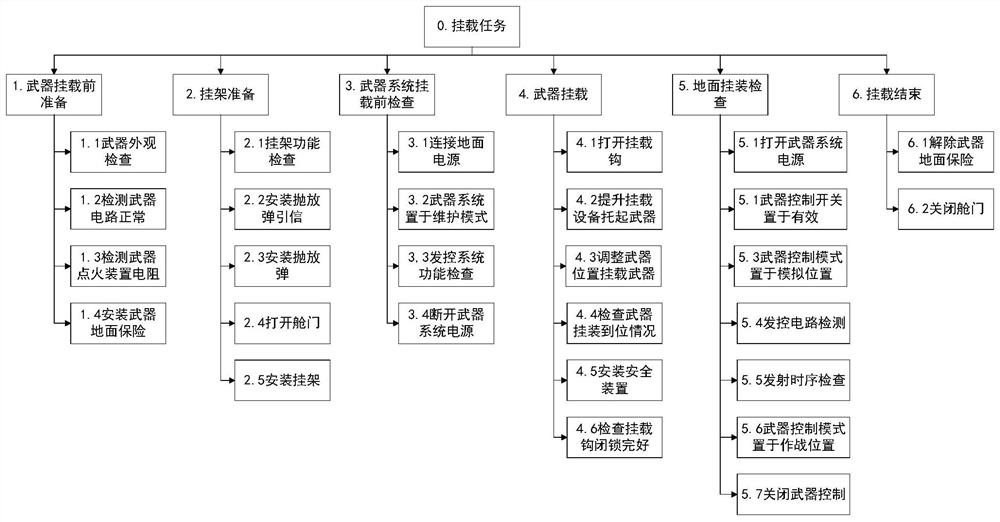

[0061] The present invention is a potential fault analysis method based on PFMEA and HRA methods, and the process is illustrated by taking the potential fault analysis in the weapon mounting task stage of a certain type of airborne weapon system as an example. The airborne weapon system has typical multi-stage mission characteristics, which are mainly divided into weapon system maintenance, mounting, flying, launching and unloading stages. There is a complex human-computer interaction process in the maintenance or mounting phase, and the potential faults caused by it may be activated during the flight or launch phase, eventually leading to serious accidents.

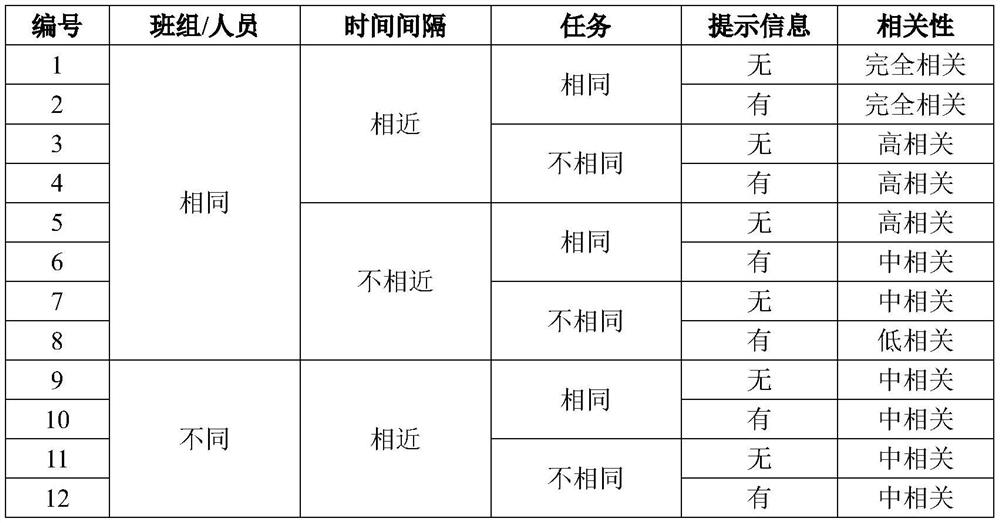

[0062] The personnel performance of tasks in the maintenance or mounting phase is affected by the coupling of equipment and environmental conditions, and the operation actions of personnel in the process have a certain correlation. The present invention fully considers the above-mentioned influence relationship, which can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com