In-situ synthesized TiB reinforced beta titanium alloy composite, and preparation method thereof

A technology of titanium-based composite materials and β-titanium alloys, which is applied in the field of in-situ self-generated TiB-reinforced β-titanium alloy composite materials and its preparation, can solve the problems of increasing the difficulty of plastic deformation, restricting the development and application of alloys, and uneven deformation. Achieve the effect of reducing the risk of crack initiation, effective refinement and uniform distribution, high stiffness and good matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

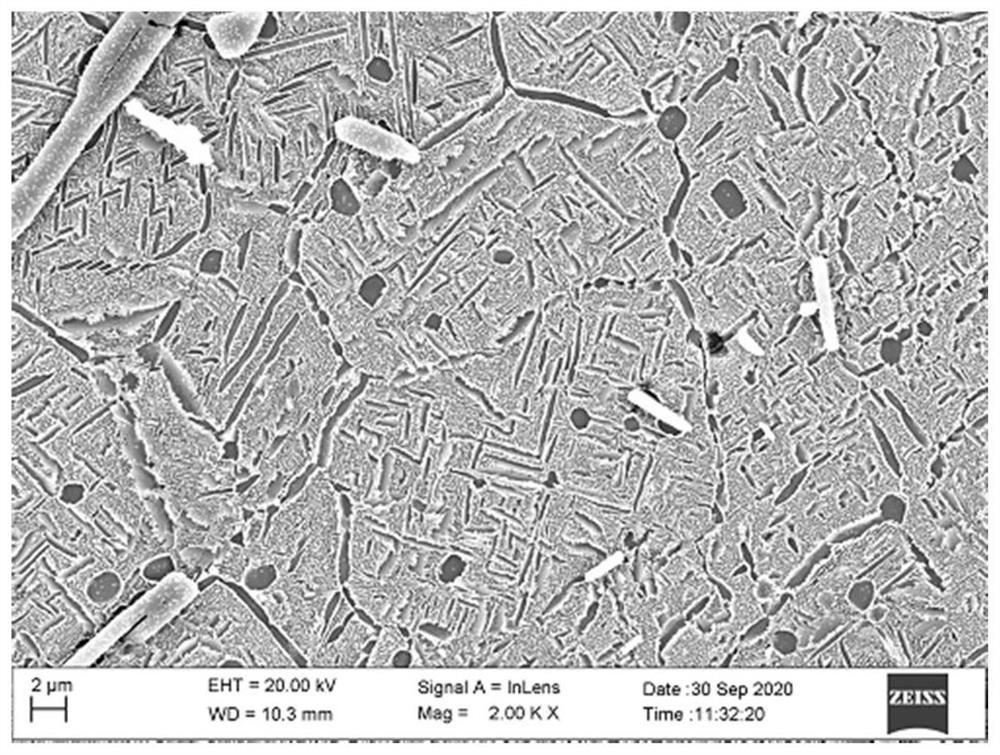

[0043] Figure 4 It is a schematic flow chart of a method for preparing an in-situ self-generated TiB reinforced β-titanium alloy composite material provided by an embodiment of the present invention, and the method includes the following steps:

[0044] S1. Prepare in-situ self-generated TiB reinforced β-titanium alloy and Ti-55531 composite material ingot by using vacuum consumable arc melting method;

[0045] S2. Combining metallographic method to obtain the phase transition point T of the titanium matrix composite ingot α+β / β , performing multi-pass piercing and near-isothermal thermoplastic deformation at the first set temperature;

[0046] S3. Performing multi-pass piercing and near-isothermal thermoplastic deformation and forging on the billet forging blank at the second set temperature;

[0047] S4. Performing multi-pass hot rolling on the modified forging billet at the third set temperature to obtain a titanium-based composite material billet;

[0048] S5. Perform ...

Embodiment 1

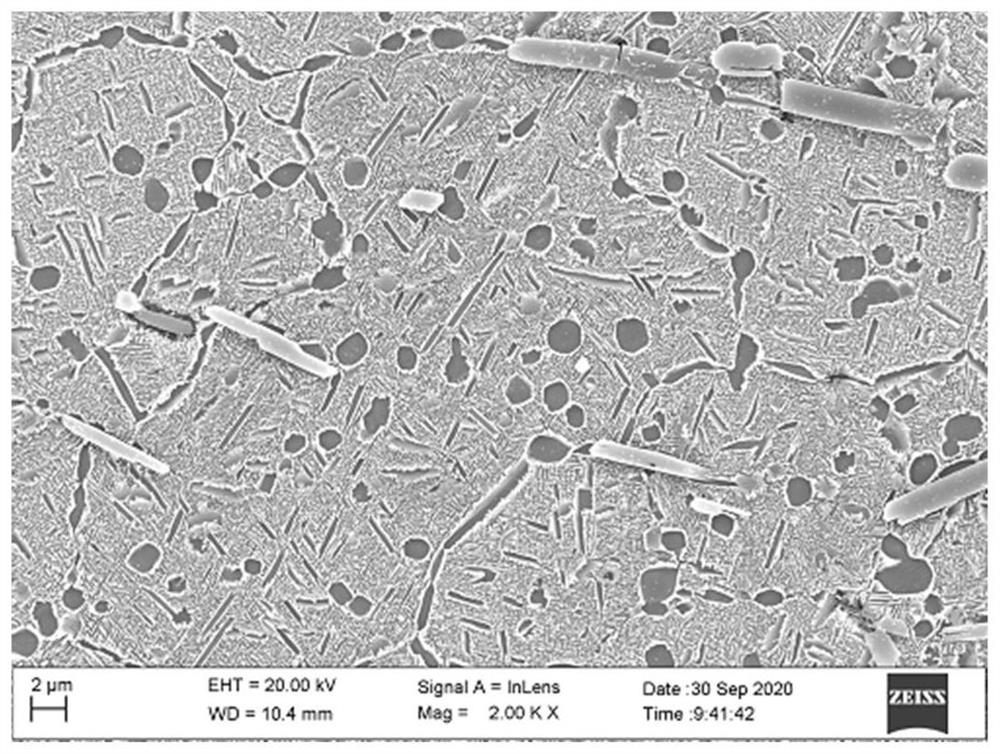

[0061] This embodiment is a preparation method of a TiB reinforced β titanium alloy Ti-55531 composite material, and the specific implementation steps are as follows:

[0062] Step 1. The composition of the composite material is designed to be 2vol.%TiB / Ti-55531, and a titanium-based composite material ingot with uniform composition is prepared by using three vacuum consumable arc melting methods, based on Ti and TiB 2 The chemical reaction of the powder realizes the in-situ self-generation of the TiB reinforcement phase.

[0063] Step 2. The phase transition point measured by metallographic method is T α+β / β =855±5°C, three passes of piercing and near-isothermal thermoplastic deformation are carried out at 1100°C, and the temperature of the isothermal forging furnace is kept at 850°C, so that the deformation of the ingot during each pass of piercing deformation is More than 80% and no cracking occurs, and the coarse primary grains and TiB long fibers are broken to the greate...

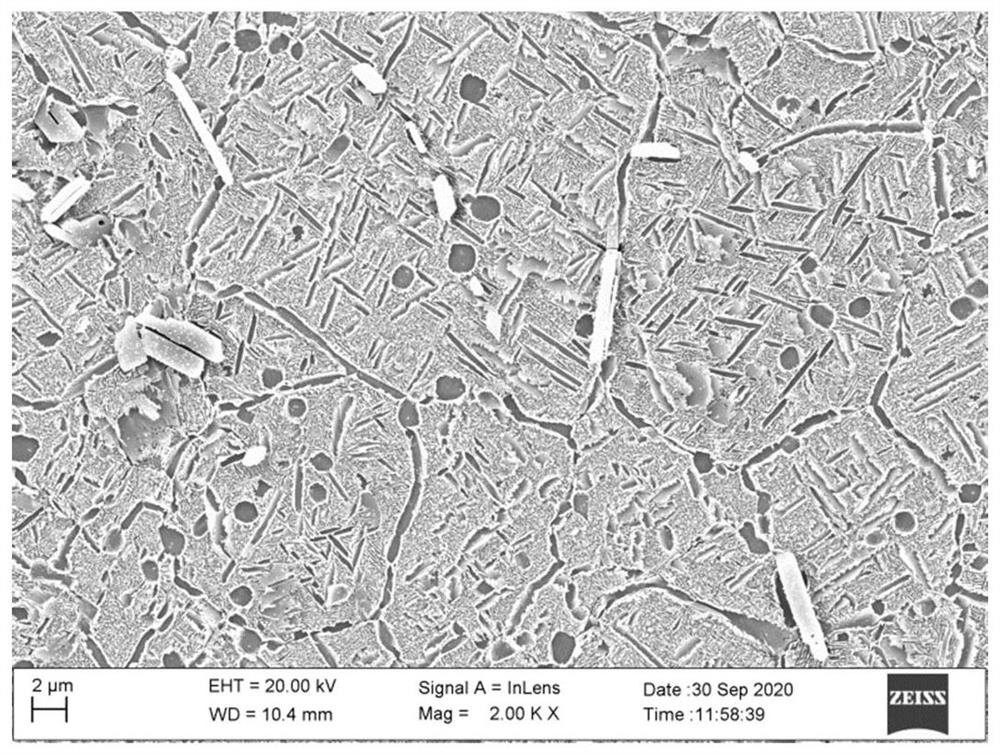

Embodiment 2

[0068] The difference between this embodiment and embodiment 1 lies in step 3, that is, to select T α+β / β -(10~20)°C temperature range Carry out four times pier drawing near isothermal thermoplastic deformation and modified forging on the blank forging blank. The morphology of the microstructure is as figure 2 shown. The mechanical performance test results are as follows R m =1419.6MPa, R p0.2=1385.1MPa, E=121.3GPa, A=9.3%, achieving a good match of ultra-high strength, high stiffness and plasticity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature tensile strength | aaaaa | aaaaa |

| Room temperature yield strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com