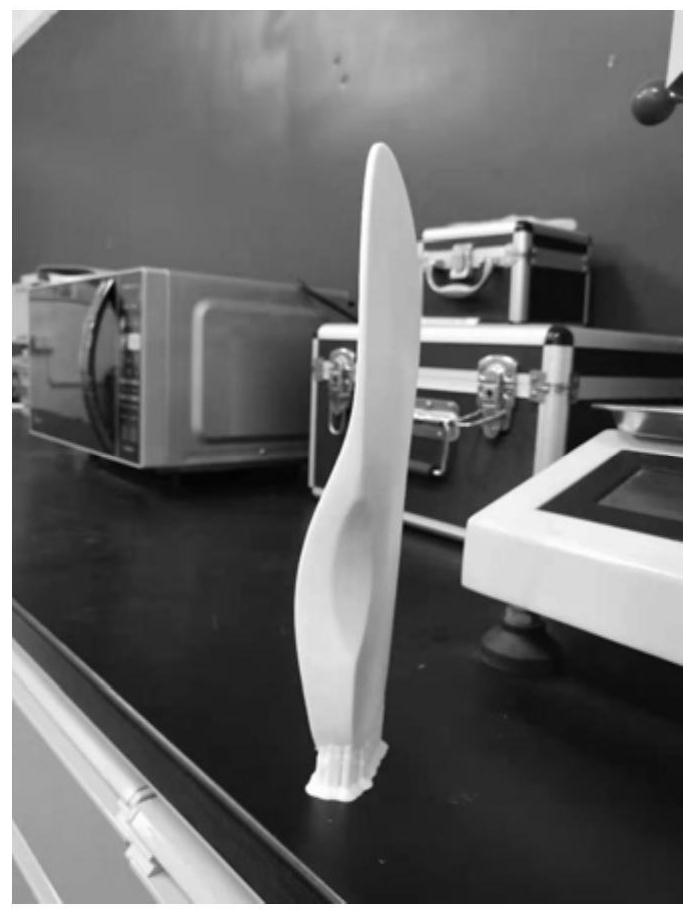

Photosensitive resin composition for photocuring 3D printing high-toughness product and preparation method of photosensitive resin composition

A 3D printing and photosensitive resin technology, applied in the chemical industry, can solve problems such as slow curing speed, affecting 3D printing accuracy, and affecting 3D printing efficiency, and achieve the effect of reducing material usage costs, breaking technology monopoly, and promoting rapid development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

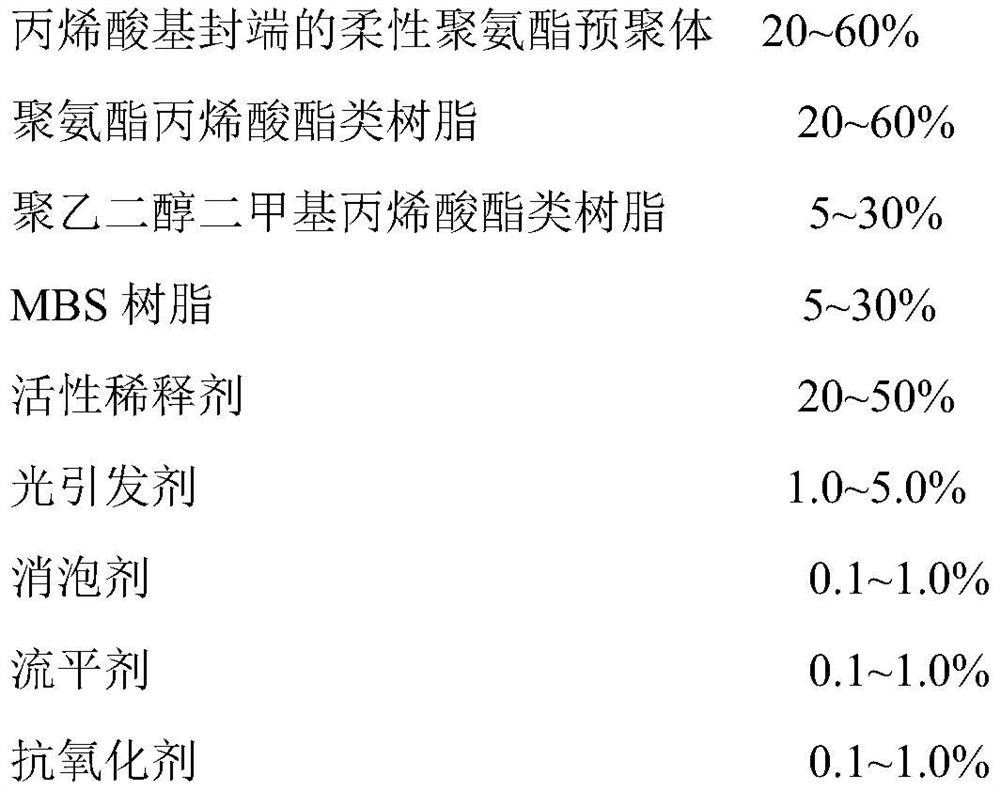

Method used

Image

Examples

Embodiment Construction

[0030] In the embodiment, the raw material source that adopts and the abbreviation in embodiment are as follows:

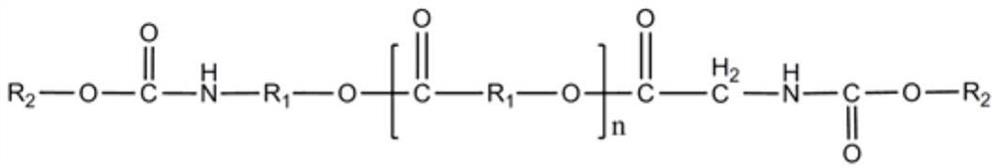

[0031] Isocyanate group-terminated polyester (ether)

[0032] Aliphatic polyester (ether) terminated by isocyanate group: purchased from Sartomer Company, abbreviated as A-1;

[0033] Alicyclic polyester (ether) terminated by isocyanate group: purchased from Sartomer Company, abbreviated as A-2;

[0034] Aromatic polyester (ether) terminated by isocyanate group: purchased from Sartomer Company, abbreviated as A-3;

[0035] polyurethane acrylate resin

[0036] Aliphatic urethane acrylate: purchased from Sartomer Company, product number CN9010, abbreviated as B-1;

[0037] Aliphatic urethane acrylate: purchased from Sartomer Company, product number CN991, abbreviated as B-2;

[0038] Polyethylene glycol dimethacrylate resin

[0039] Polyethylene glycol dimethacrylate resin 1: purchased from Sartomer Company, product number SR210, abbreviated as C-1;

[0040] P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com