Power wire and cable protection sleeve

A technology for wires and cables and protective sleeves is applied in the field of laying power pipelines, which can solve the problems of the influence of installation quality proficiency, the difficulty of disassembly and adjustment of the pipe body, and the high installation cost, so as to reduce friction, increase the contact area, and facilitate disassembly. with adjusted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

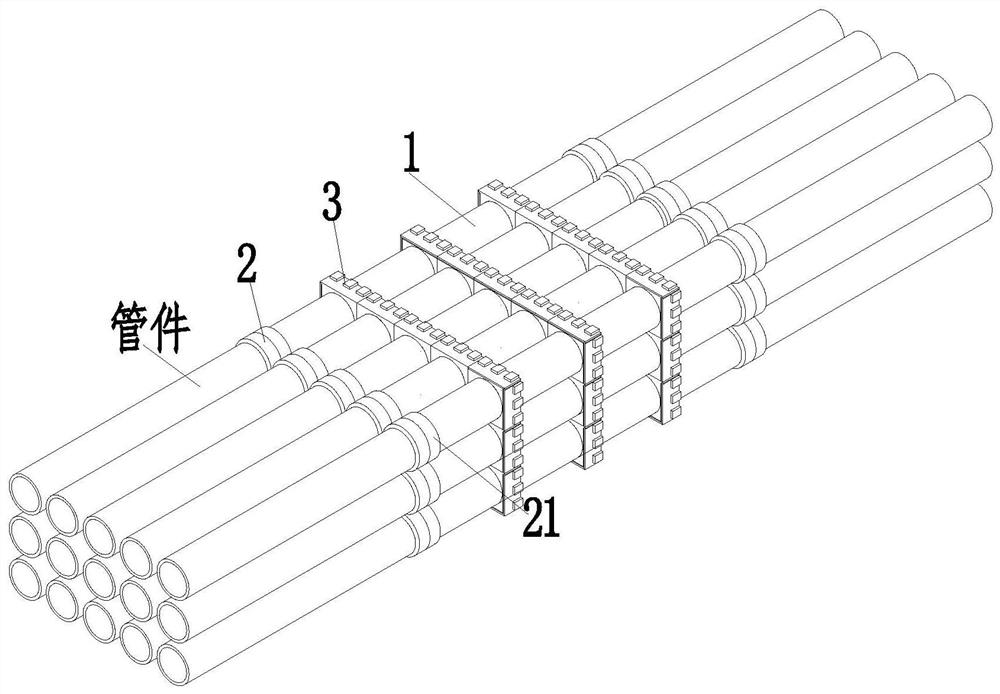

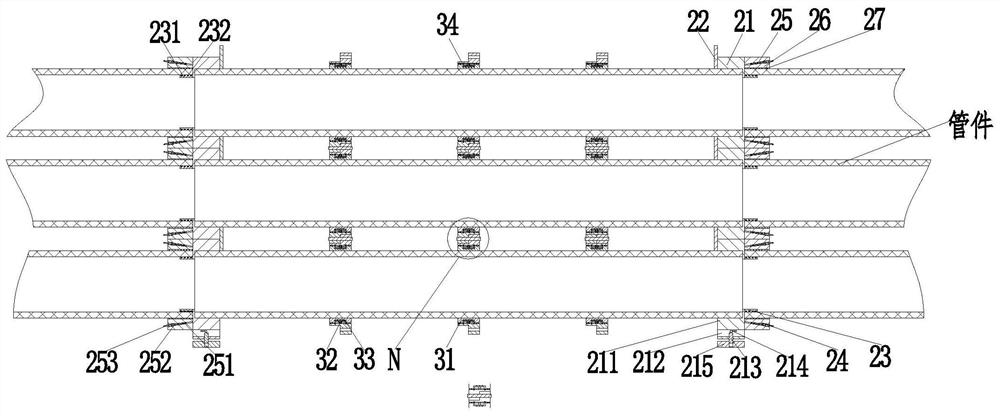

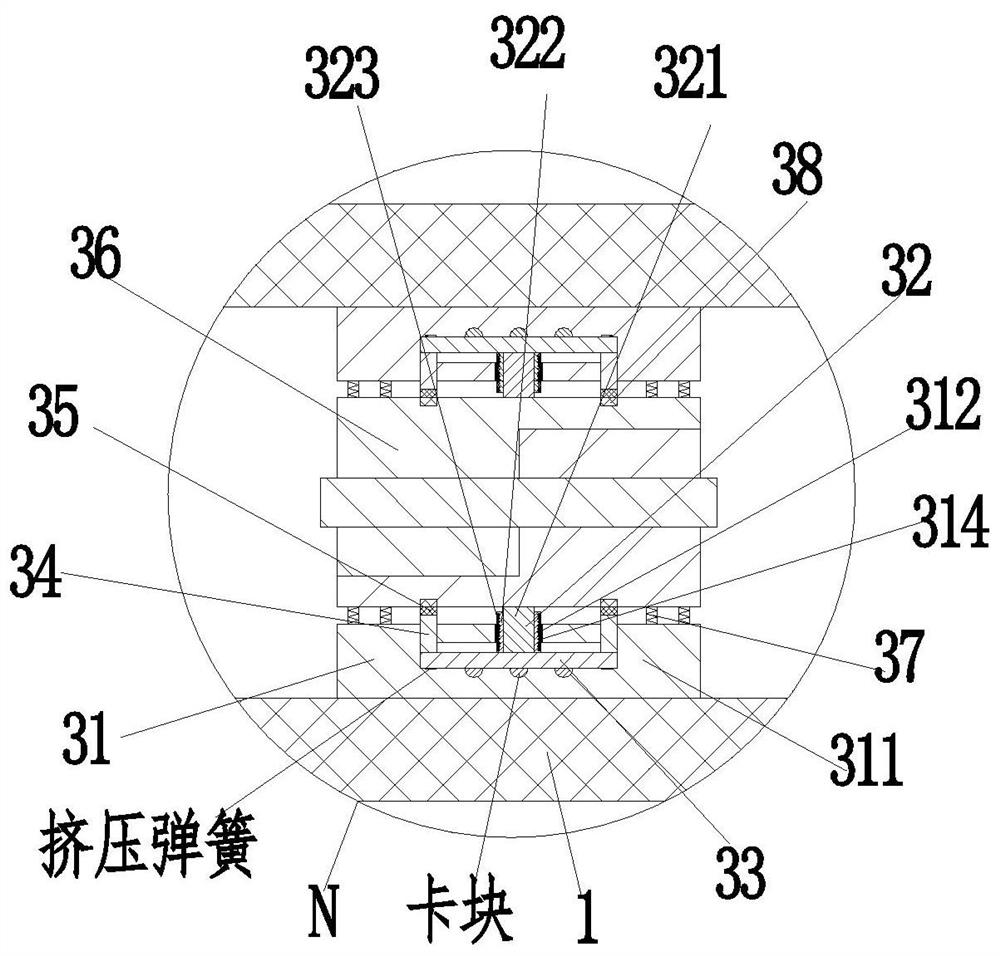

[0028] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 6 , to further elaborate the present invention.

[0029] A protective sleeve for power wires and cables, comprising a tube body 1, a connecting frame 2 and an arrangement frame 3, the outer end faces of the left and right sides of the tube body 1 are symmetrically and fixedly installed with the connecting frame 2, and the middle part of the tube body 1 is evenly and fixedly installed with an arrangement frame 3; where:

[0030]The connecting frame 2 includes a fixed ring 21, an arc-shaped baffle 22, a snap ring 23, a positioning ring 24, a tapered fastener 25, a tapered bush 26, a rubber plate 27 and a rubber block 28, and the pipe body 1 is left and right The outer end faces on both sides are symmetrically fixed with a fixed ring 21, the upper side of the fixed ring 21 is fixedly installed with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com