Vegetable cycle production line

A production line and vegetable technology, which is applied in the field of leafy vegetable chain-type automatic circulation production line and vegetable circulation production line, can solve the problem of lack of assembly line operation procedures and methods, impossible to achieve unmanned process management, and vegetable production methods that do not have the ability to move function and other issues, to achieve the effect of improving yield, water and fertilizer utilization rate, light energy utilization rate, and labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

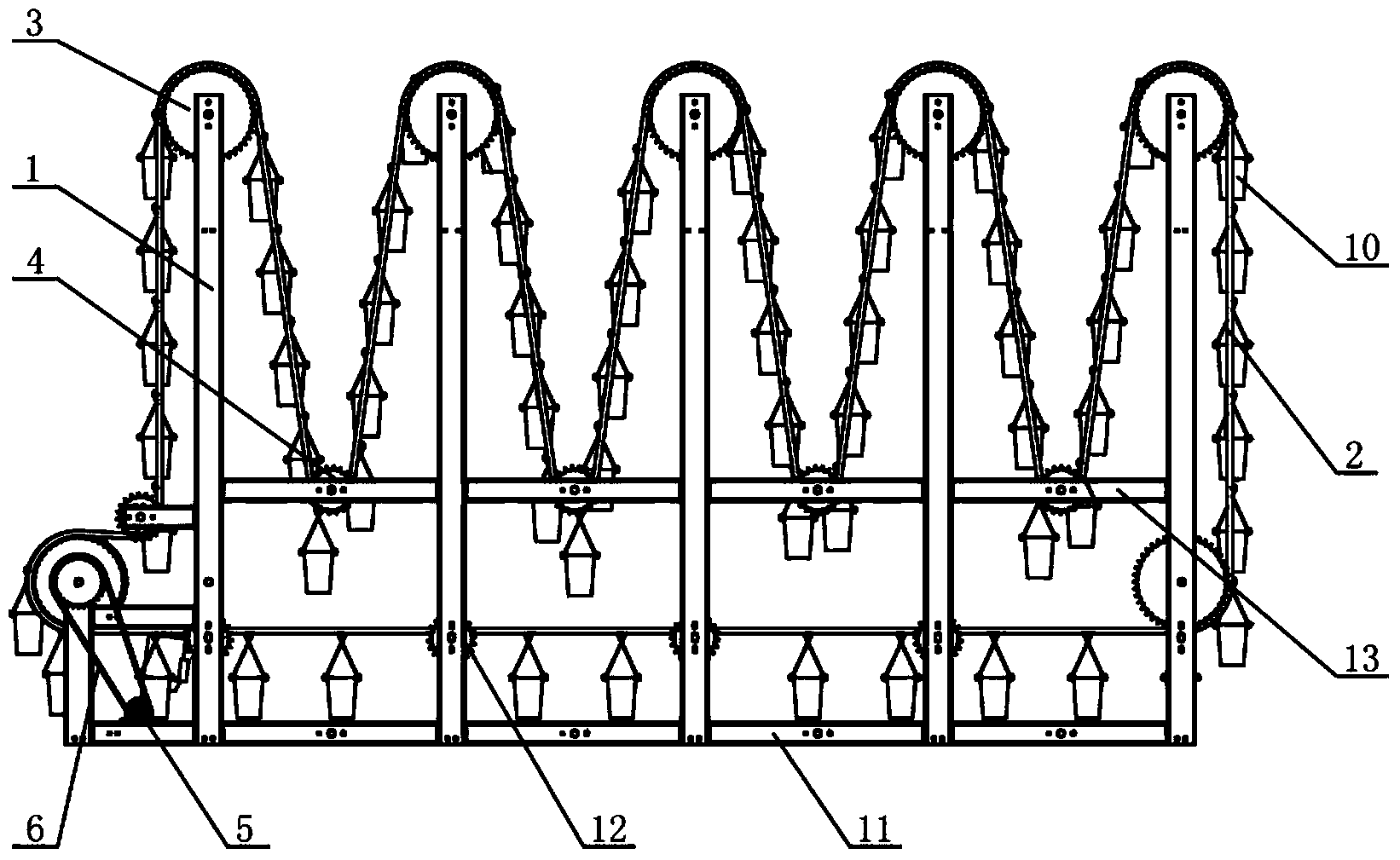

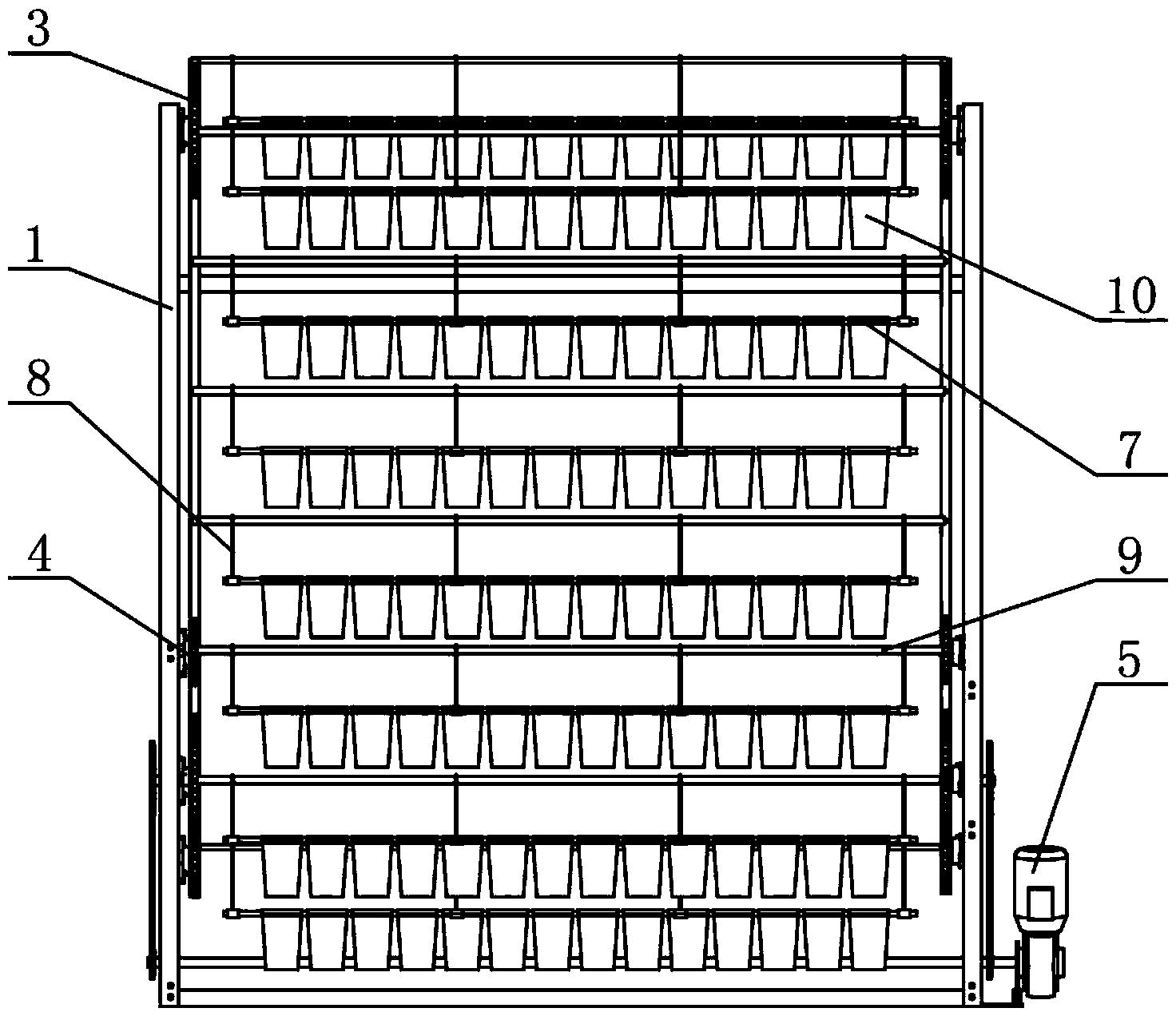

[0027] Such as figure 1 with figure 2 As shown, the vegetable recycling production line provided by the embodiment of the present invention includes two sets of oppositely arranged support units, wherein each set of support units includes a number of columns 1 arranged at intervals, and the columns 1 are installed on the base 11 , the column 1 can be made more stable and firm through the base 11 .

[0028] The columns 1 can be combined according to the needs. The height of the columns 1 is usually more than 2 meters, and the distance between the columns 1 is usually 0.9-1.5 meters, which can be adjusted appropriately according to the needs. The width between two groups of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com