Full-automatic cloth-applying and drying unit, and working method thereof

A dryer and cloth applicator technology, which is applied in chemical instruments and methods, lamination auxiliary operations, lamination devices, etc., can solve the problem that it takes a lot of time to wait for the finished product to be aired, the process quality is difficult to guarantee, and the process is multi-station. and other problems, to achieve the effect of shortening the process operation time, stable product quality, and reducing the number of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

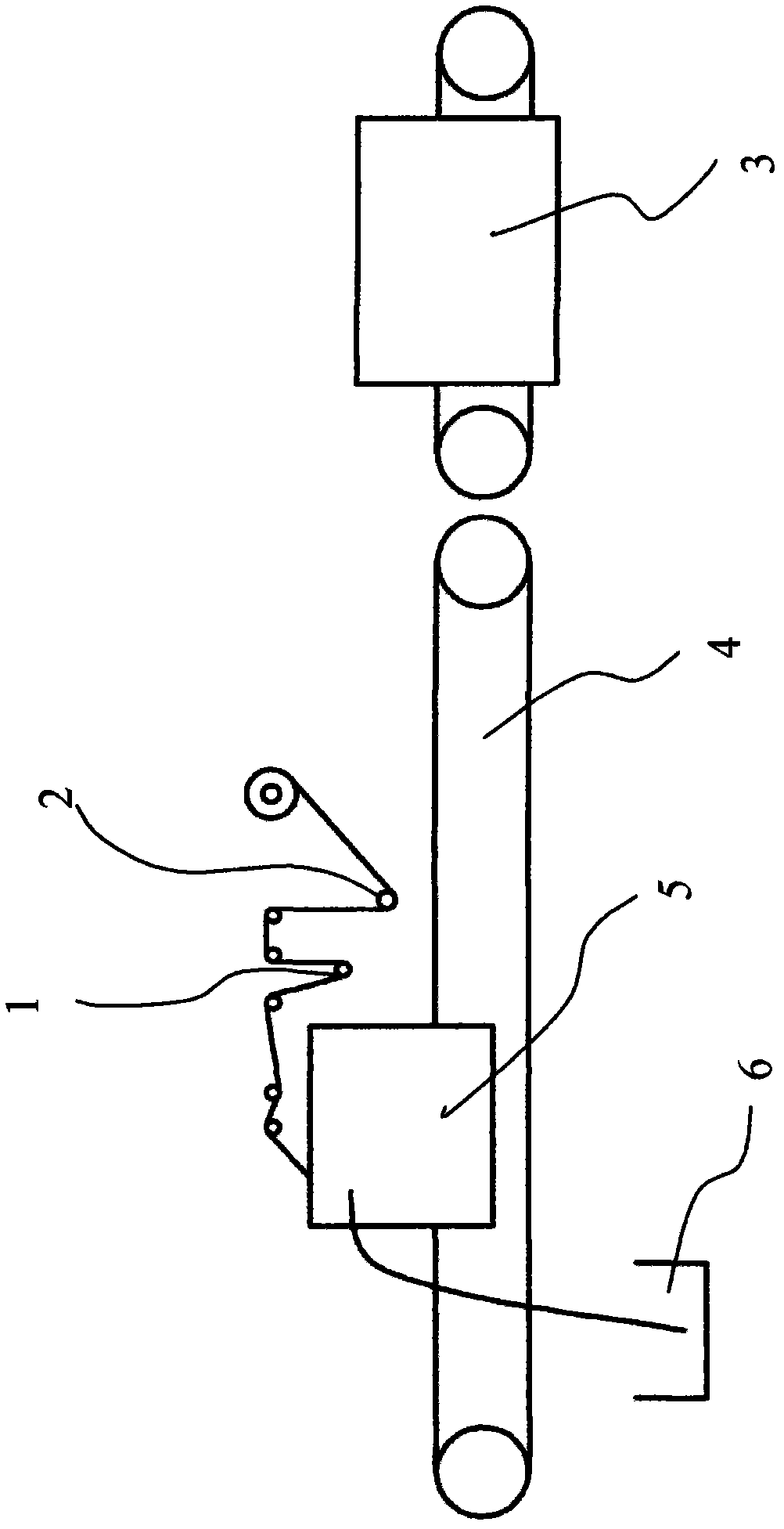

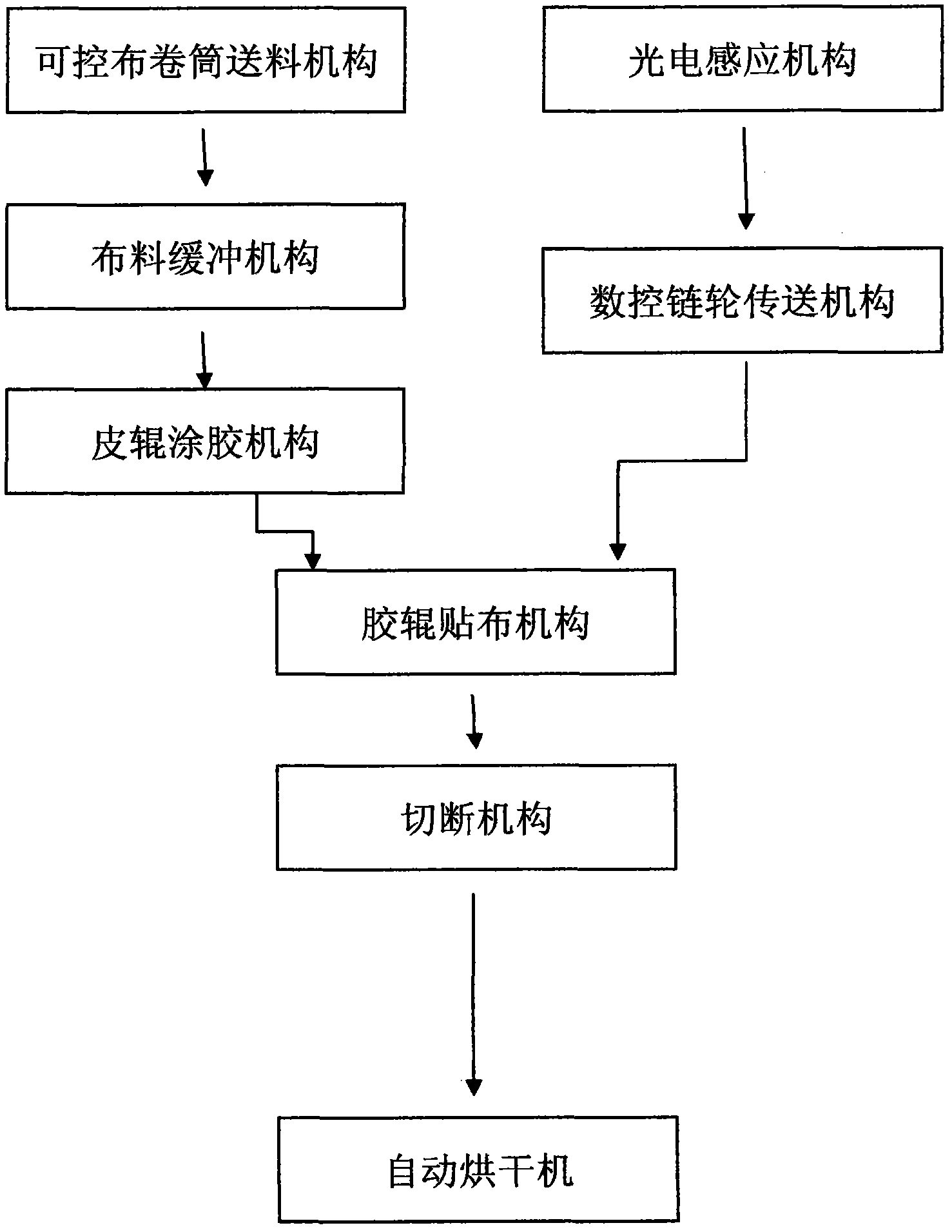

[0018] Fully automatic patching drying unit, including a patching machine assembly and a dryer assembly, the patching machine assembly includes a cloth conveying mechanism, a plate conveying mechanism, a rubber roller pasting mechanism 5 and a cutting mechanism, and a cloth conveying mechanism It is composed of a controllable cloth reel feeding mechanism 1, a cloth buffer mechanism 2, and a top roller gluing mechanism. The plate conveying mechanism includes a photoelectric sensor mechanism and a digitally controlled sprocket conveying mechanism 4. The dryer assembly is composed of a conveying device and a drying box. 3, the CNC sprocket transmission mechanism 4 is fixed on the frame, the rubber roller patching mechanism 5 is arranged above the CNC sprocket transmission mechanism 4, and the CNC sprocket transmission mechanism 4 is docked with the transmission device of the dryer. A drying box 3 is arranged above the conveying device of the drying machine.

[0019] The drying ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com