Method of manufacturing semiconductor device

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of decreased mechanical strength of semiconductor wafers, prone to fractures or cracks, and difficult handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

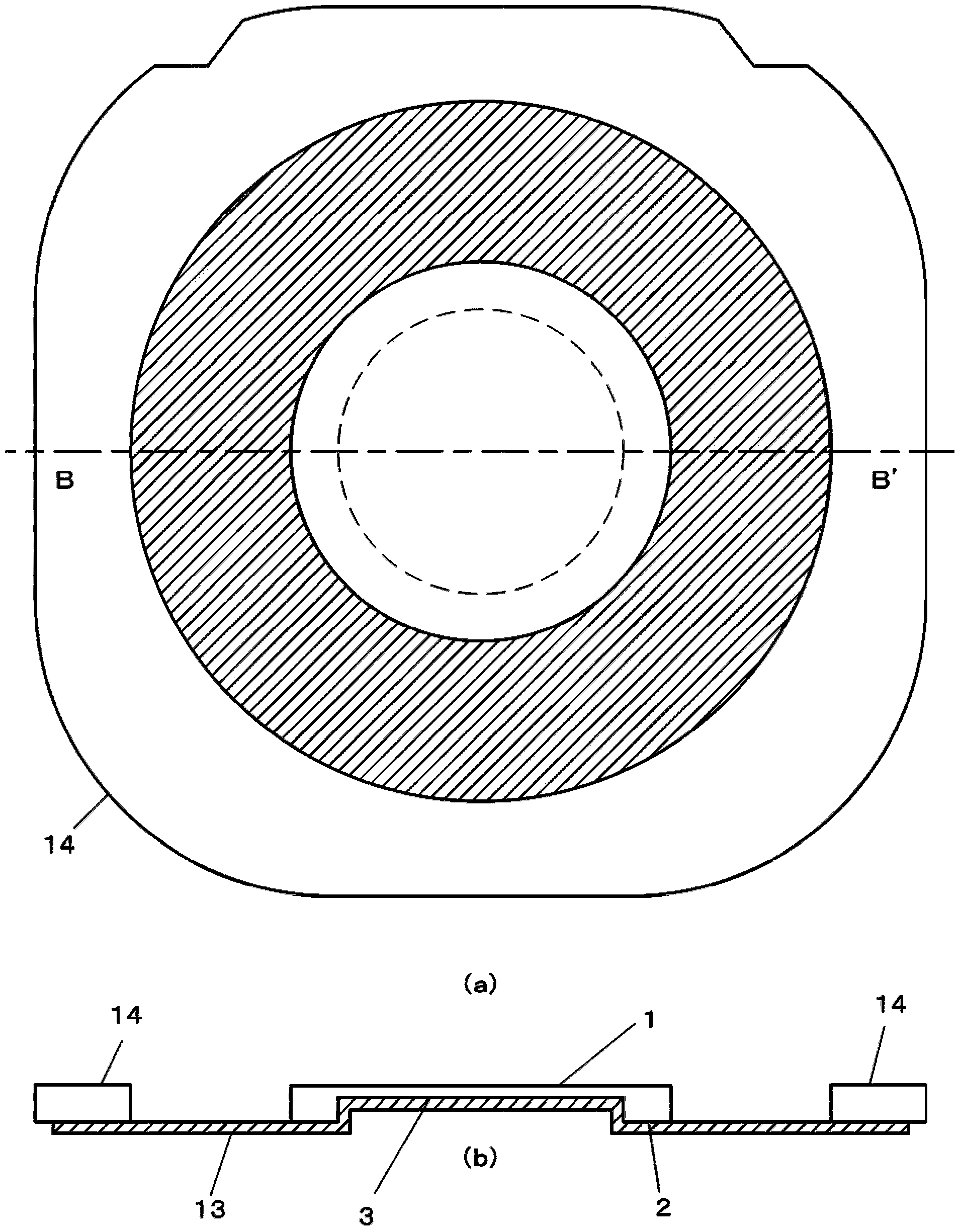

[0046] Figure 18 The semiconductor wafer 1 whose central part is thinned and the outer peripheral part becomes the ring-shaped reinforcing part 2 is shown in . Figure 18 (a) is a top view of a semiconductor wafer 1, Figure 18 (b) is Figure 18 (a) A-A' sectional view.

[0047] Depend on Figure 18 (b) It can be seen that the thick ring-shaped reinforcing portion 2 is formed on the outer peripheral portion of the back surface of the semiconductor wafer 1 , and the thin back surface concave portion 3 is formed on the central portion of the back surface of the semiconductor wafer 1 .

[0048] Depend on Figure 18 (a) It can be seen that the element formation region 6 in which the semiconductor device 4 is formed exists in the rear surface recess 3 , and the chip dividing line 7 is formed in the element formation region 6 for cutting the element formation region 6 to obtain individual semiconductor devices 4 . In addition, the area other than the element formation area 6 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com