CPI film with water-oxygen barrier property and preparation method thereof

A water-oxygen barrier and film technology, which is applied in semiconductor/solid-state device manufacturing, identification devices, instruments, etc., can solve the problems of high cost, difficulty in large area, continuous scale preparation, etc., and achieve the effect of avoiding yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

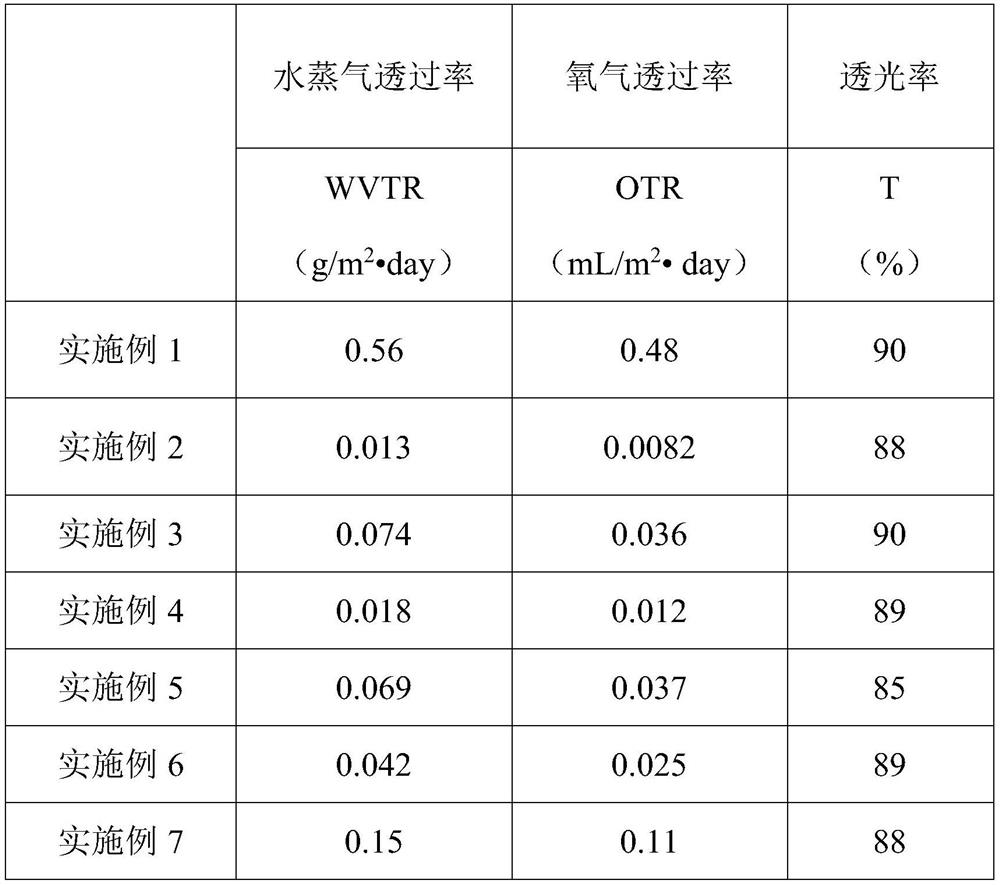

Examples

Embodiment 1

[0024] A kind of CPI film with water and oxygen barrier performance, its preparation method comprises:

[0025] S1. Add 10mL of tetrabutyl titanate into 30mL of absolute ethanol, stir and mix at room temperature for 2 hours, then add 15mL of tetrabutylammonium orthosilicate, stir and mix evenly, add 0.5mL of tetrabutylammonium hydroxide and 10mL of absolute ethanol at room temperature Mix the solution, stir and mix evenly to obtain the coating solution;

[0026] S2. Apply the above-mentioned coating solution on the surface of a transparent polyimide (CPI) base film (90% visible light transmittance, about 70 μm in thickness) by spin coating, and the thickness of the coating is about 10 μm. After the coating is completed Transfer to a high and low temperature alternating humid heat box, under the condition of relative humidity of 80%, raise the temperature to 60°C at a rate of 1°C / min, keep it for 0.5h, continue to raise the temperature to 120°C, keep it for 1.5h, take it out an...

Embodiment 2

[0028] A kind of CPI film with water and oxygen barrier performance, its preparation method comprises:

[0029] S1, the transparent polyimide (CPI) base film (visible light transmittance 90%, thickness is about 70 μ m) is immersed in the H concentration of 30wt%. 2 o 2 In the solution, heat preservation treatment at 40°C for 0.5h, take it out, wash it with a large amount of deionized water, and dry it to obtain a transparent polyimide (CPI) base film after surface activation treatment;

[0030] S2. Add 10mL of tetrabutyl titanate to 30mL of absolute ethanol, stir and mix at room temperature for 2 hours, then add 15mL of ethyl orthosilicate, stir and mix evenly, add 0.5mL of tetrabutylammonium hydroxide and 10mL of absolute ethanol at room temperature Mix the solution, stir and mix evenly to obtain a coating solution;

[0031] S3. Apply the above-mentioned coating liquid on the surface of the transparent polyimide (CPI) base film after the surface activation treatment by the ...

Embodiment 3

[0033] A kind of CPI film with water and oxygen barrier performance, its preparation method comprises:

[0034] S1, the transparent polyimide (CPI) base film (visible light transmittance 90%, thickness is about 70 μ m) is immersed in the H concentration of 30wt%. 2 o 2 In the solution, heat preservation treatment at 30°C for 1 hour, rinse with a large amount of deionized water after taking out, and dry to obtain a transparent polyimide (CPI) base film after surface activation treatment;

[0035] S2. Add 6g of aluminum isopropoxide to 30mL of absolute ethanol, stir and mix at room temperature for 2 hours, then add 15mL of tetrabutylammonium hydroxide and 10mL of absolute ethanol, add 15mL of tetrabutylammonium hydroxide and 10mL of absolute ethanol at room temperature and mix well solution, after stirring and mixing uniformly, a coating liquid is obtained;

[0036] S3. Apply the above-mentioned coating liquid on the surface of the transparent polyimide (CPI) base film after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com