Silver nanowire conductive film and preparation method thereof

A technology of silver nanowires and conductive films, which is applied to equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, conductive layers on insulating carriers, etc., and can solve problems such as unsatisfactory water and oxygen barriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

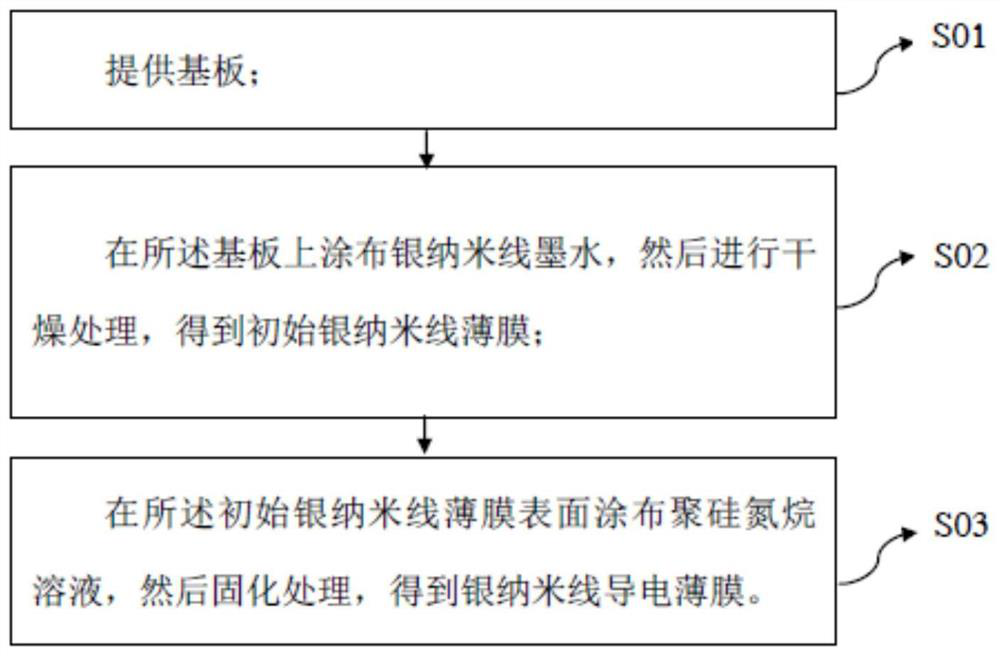

[0018] On the one hand, the embodiment of the present invention provides a kind of preparation method of silver nanowire conductive thin film, such as figure 1 Shown, this preparation method comprises the steps:

[0019] S01: Provide the substrate;

[0020] S02: coating the silver nanowire ink on the substrate, and then performing drying treatment to obtain an initial silver nanowire film;

[0021] S03: Coating a polysilazane solution on the surface of the initial silver nanowire film, and then curing to obtain a silver nanowire conductive film.

[0022] The preparation method of the silver nanowire conductive film provided by the embodiment of the present invention, after the silver nanowire ink is made into the initial silver nanowire film on the substrate, the polysilazane solution is coated on the surface of the initial silver nanowire film and solidified to form a polysilazane solution. Silazane cured layer; polysilazane matches the surface polarity of silver simple sub...

Embodiment 1

[0042] A preparation method of a silver nanowire transparent conductive film, comprising the steps of:

[0043] Preparation of polysilazane solution: the mass fraction of polysilazane resin is 1%, the mass fraction of surface leveling agent Glide-432 is 0.02%, the mass fraction of surface wetting agent DISPERBYK-168 is 0.03%, and the balance is butyl acetate and ethylene glycol dimethyl ether mixture (mass ratio 1:1). In the structural formula of polysilazane resin, R 1 and R 2 Both are H, and the molecular weight is 1000.

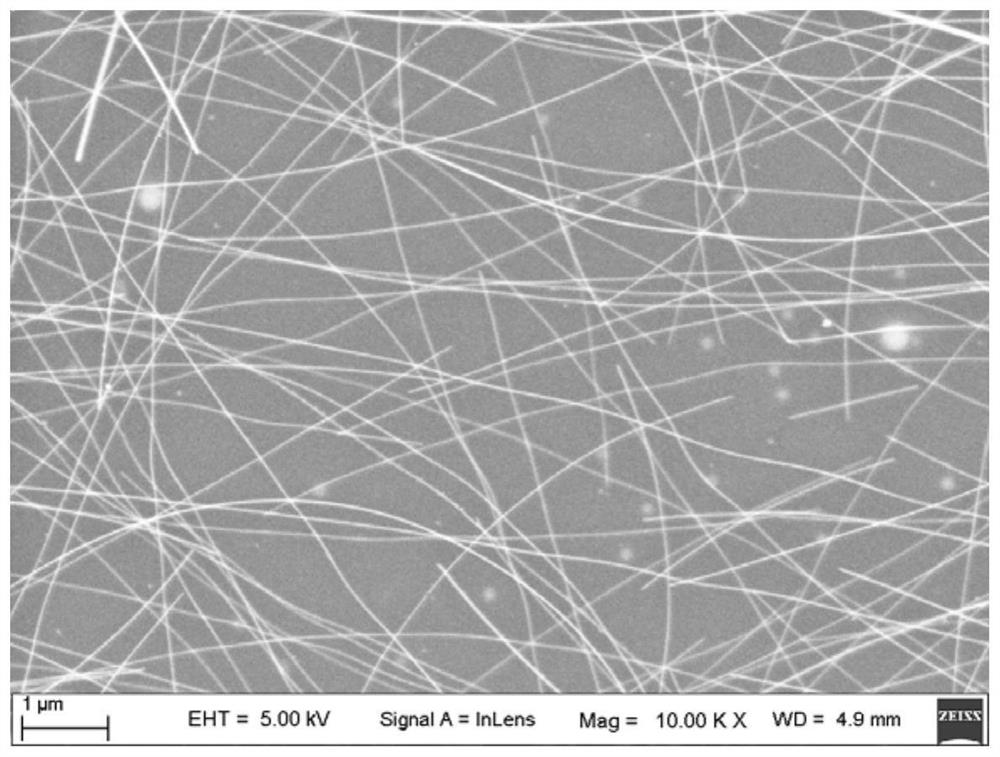

[0044] Coat silver nanowire ink on a flexible transparent substrate, place it in an oven at 100°C for 20 minutes, and dry it into a silver nanowire film; then coat the above-mentioned polysilazane solution on the surface of the silver nanowire film, and place it at a temperature of 20 ℃, and a relative humidity of 95% in an oven for 10 hours to obtain a silver nanowire transparent conductive film.

Embodiment 2

[0046] A preparation method of a silver nanowire transparent conductive film, comprising the steps of:

[0047] Preparation of polysilazane solution: the mass fraction of polysilazane resin is 10%, the mass fraction of surface leveling agent Glide-432 is 0.5%, the mass fraction of surface wetting agent DISPERBYK-168 is 0.5%, and the balance is n-hexane, A mixture of n-pentane (mass ratio 1:1). In the structural formula of polysilazane resin, R 1 for H, R 2 for CH 3 , the molecular weight is 2200.

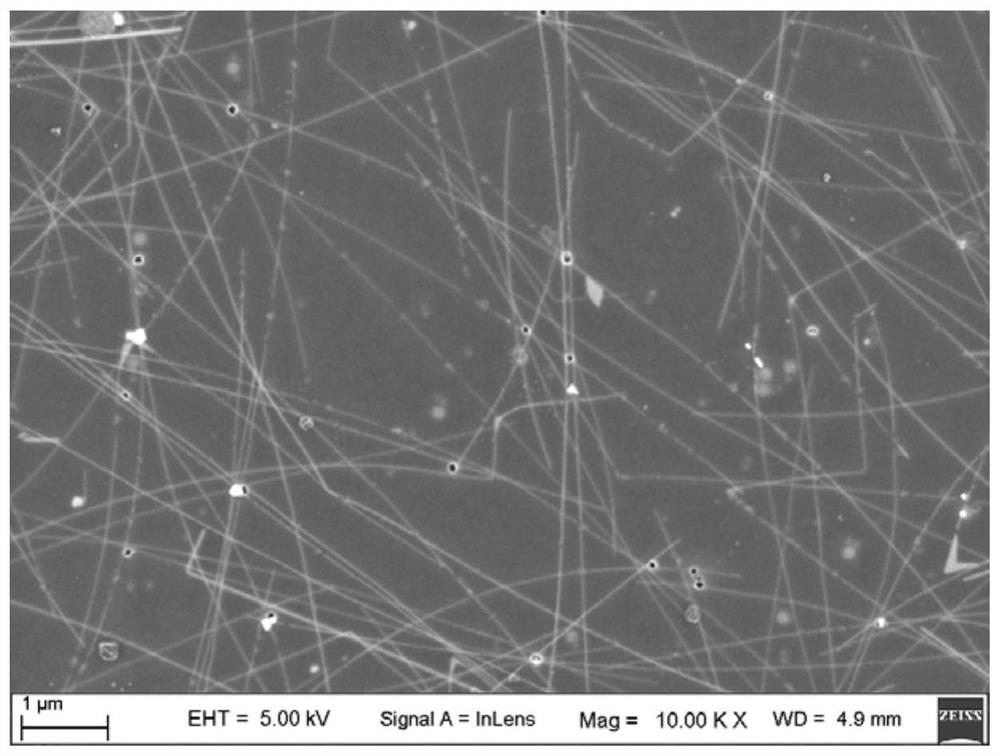

[0048] Coat silver nanowire ink on a flexible transparent substrate, place it in an oven at 100°C for 20 minutes, and dry it into a silver nanowire film; then coat the above-mentioned polysilazane solution on the surface of the silver nanowire film, and place it at a temperature of ℃, and the relative humidity is 60% in an oven for curing for 30 minutes to obtain a silver nanowire transparent conductive film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com