Support joint of cable dome structure and machining method

A processing method and cable dome technology, applied in building construction, special data processing applications, instruments, etc., can solve problems such as uneven stress distribution of support nodes, affecting structural safety and stability, increasing difficulty of on-site installation, etc. Smooth and beautiful, improve safety and stability, reduce the effect of construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0029] Topology optimization is a mathematical method to optimize the distribution of materials in a specified area according to boundary conditions and performance indicators. The invention utilizes the principle of topology optimization to optimize and analyze the cast steel support nodes of the cable dome, and obtains and designs a new type of support node of the cable dome structure based on the optimized structure, which can greatly reduce the support nodes on the basis of satisfying the bearing capacity of the nodes self-respect.

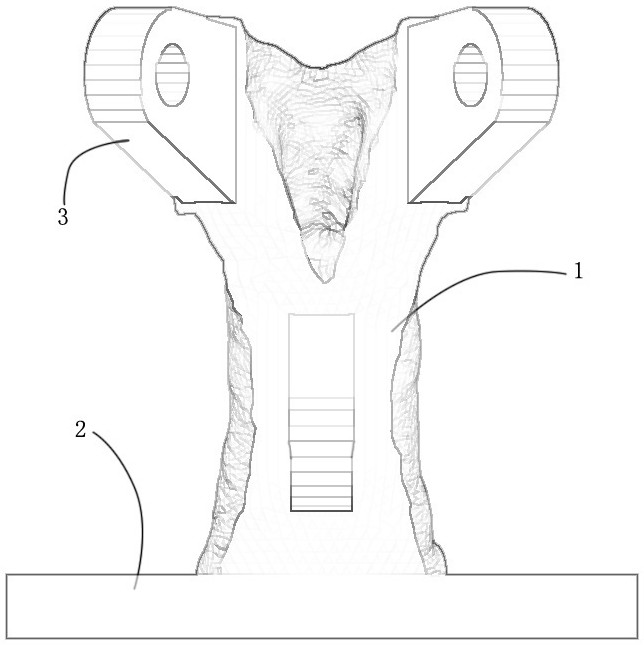

[0030] Such as Figure 2 to Figure 5 As shown, a support node of a cable dome structure includes a support body 1, a bottom plate 2 and three ear plates 3, the support body 1 inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com