Oil separation and collection system for swill treatment

A grease separation and collection system technology, applied in multi-stage water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of poor grease separation effect, labor dependence, waste of resources, etc., and achieve oil discharge The effect is environmentally friendly and healthy, saves space, and reduces the effect of wastewater odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The steps of swill treatment include dehydration, deoiling, sorting, drying and sterilization, crushing of materials, etc. A solid-liquid separation system for swill treatment in the present invention is the dehydration part in swill treatment. The oil separation and collection system for swill treatment is mainly a device for deoiling liquid after the solid-liquid separation device installed on the swill treatment vehicle.

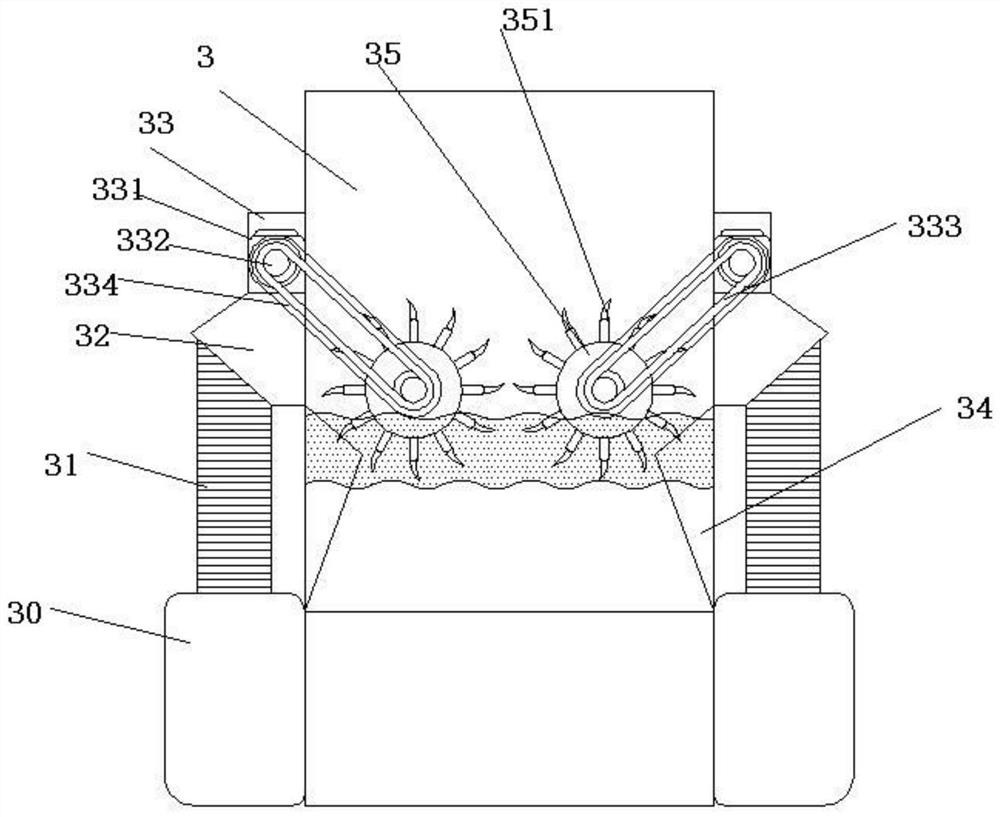

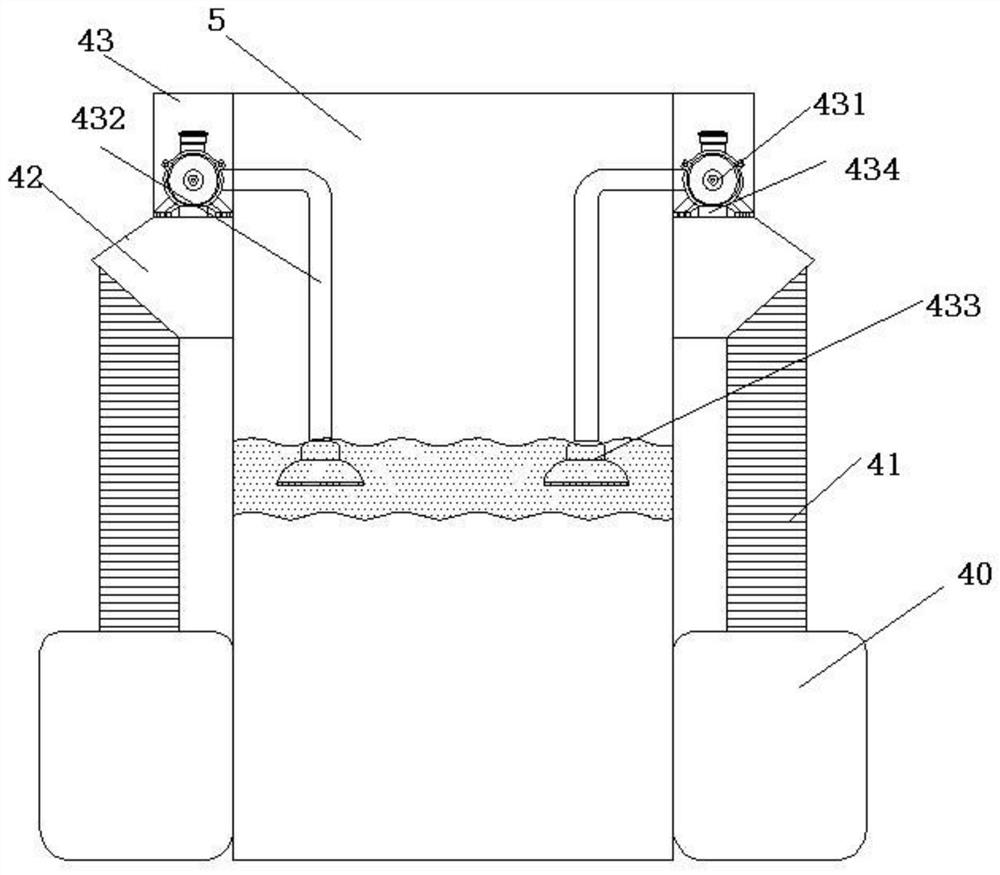

[0034] A grease separation and collection system for swill treatment, comprising a liquid delivery chamber, a water pump 2, a first deoiling chamber 3, a second deoiling chamber 4, and a wastewater treatment chamber 5, the liquid delivery chamber is used for separating the solid-liquid separation device The liquid is sent to the first deoiling chamber 3, the first deoiling chamber 3 is fixedly connected with the liquid sending chamber and the second liquid sending chamber 4 respectively, and the first deoiling chamber 3 and the second deoiling chamb...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is that the length of the first deflector 73 is shorter than that of the second deflector 73 .

Embodiment 3

[0043] The difference between this embodiment and Embodiment 1 is that the deodorizing device is fixedly installed in the middle position outside the grease separating device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com