An intelligent petrochemical fire extinguishing equipment system

A technology of petrochemical and fire extinguishing equipment, applied in fire rescue, etc., can solve the problems of injury, fireman's physical exertion, easy to knock down, etc., and achieve the effects of reducing impact, convenient observation of fire, and reducing physical consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

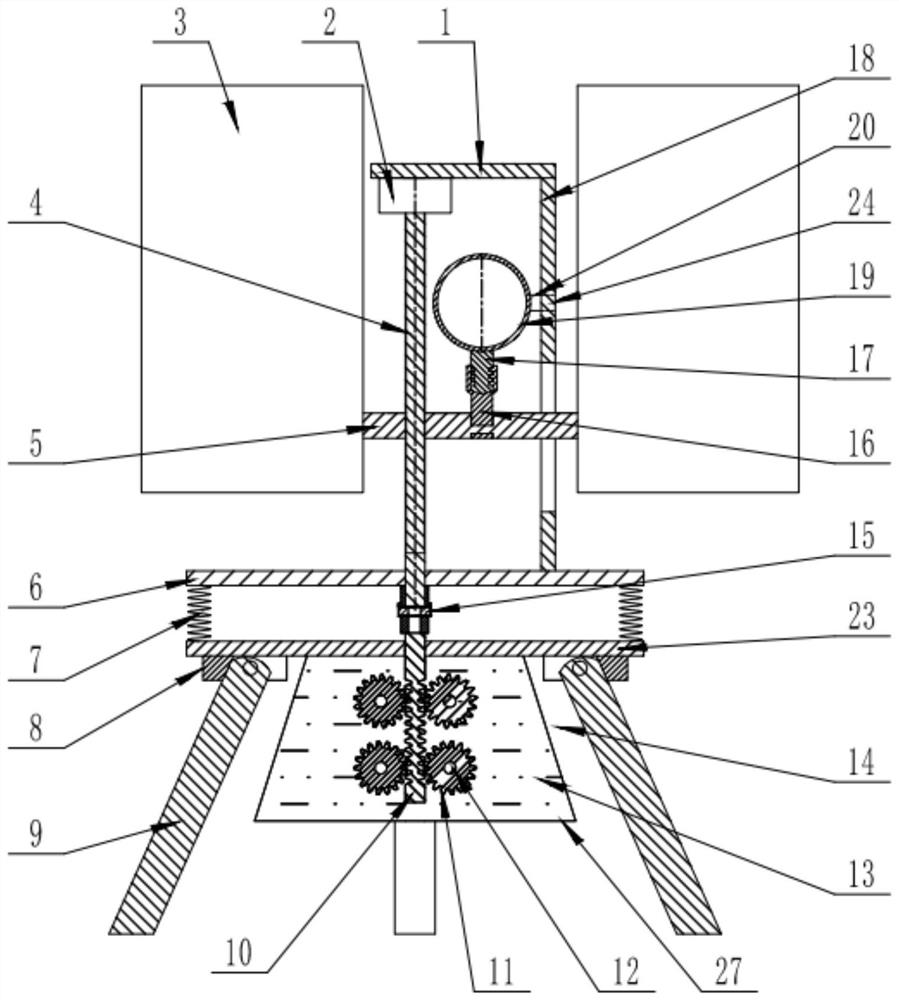

Method used

Image

Examples

Embodiment 1

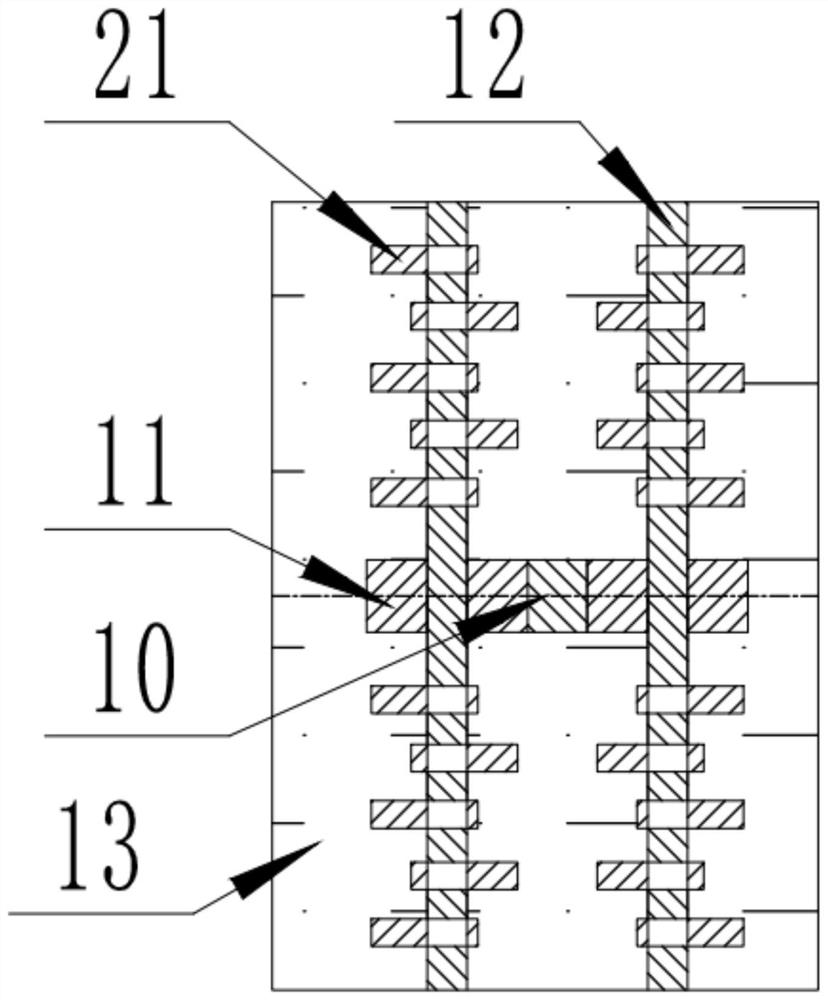

[0041] Such as image 3 As shown, a plurality of cams 21 are respectively fixedly arranged on the four rotating shafts 12, and the gear rack 10 meshes with the gear 11 to drive the rotating shaft 12 to rotate, thereby driving the plurality of cams 21 on the rotating shaft 12 to rotate. Since the left and right sides of the rack 10 The rotation direction of the gear 11 is opposite, and the cams 21 on the left and right sides of the rack 10 all support the buffer body inside the buffer structure 14 in opposite directions.

Embodiment 2

[0043] Such as Figure 6 , 7 As shown, on the basis of Embodiment 1, the non-Newtonian fluid material 13 in the buffer structure 14 is replaced by a rubber material 22. At this time, the structure in the buffer structure 14 is set as Figure 6 As shown, the cam 21 is arranged on the housing 27. When the cam 21 rotates, the front end of the cam 21 contacts with the rubber material 22 and generates friction to buffer the external force.

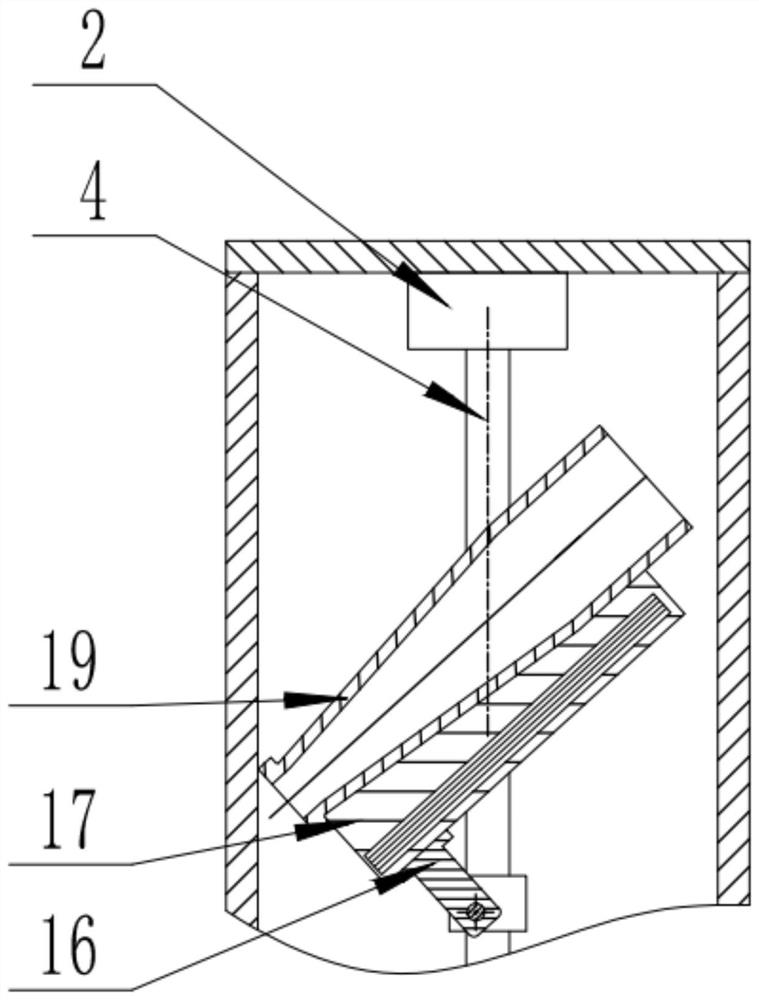

Embodiment 3

[0045] Such as Figure 4 , 5 As shown, a toggle shaft 25 is fixedly connected to one side of the cam 21, and a toggle groove 26 matched with the toggle shaft 25 on the adjacent cam 21 is provided on the other side of the cam 21, and the two sides of the gear 11 are similar. The two cams 21 on both sides of the gear 11 are fixedly connected to the rotating shaft 12, and the remaining cams 21 on both sides of the gear 11 are flexibly connected to the rotating shaft 12, and each cam 21 is staggered by a certain angle around the rotating shaft 12. On the first layer of cams 21 on both sides of the gear 11 The toggle shaft 25 is correspondingly inserted into the toggle groove 26 on the second layer of cam 21, and so on, as Figure 4 , 5 As shown, when the rotating shaft 12 rotates clockwise, it drives the first layer of cams 21 on both sides of the gear 11 to rotate, and when the cam 21 rotates to a certain angle, the toggle shaft 25 rotates to the toggle groove 26 on the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com