Flexible production control system based on multiple agents

A control system and flexible production technology, applied in general control system, control/adjustment system, program control, etc., to achieve the effect of preventing collision, facilitating code reorganization mechanism, and improving scheduling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

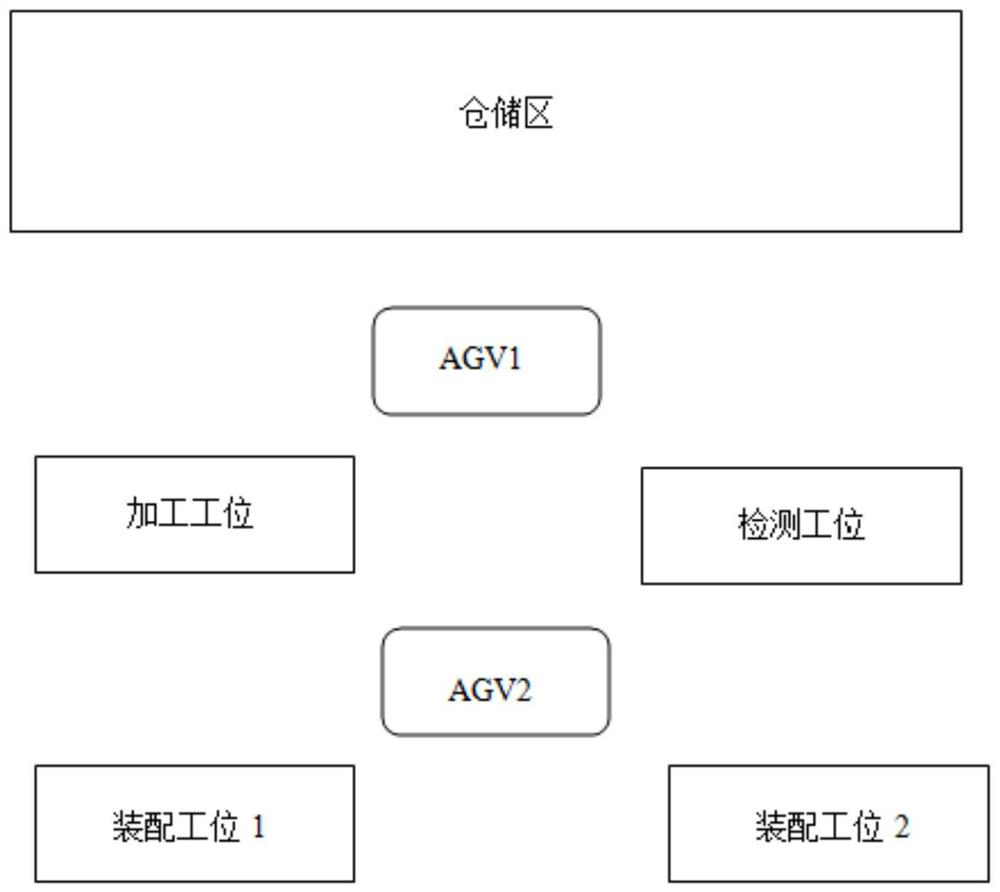

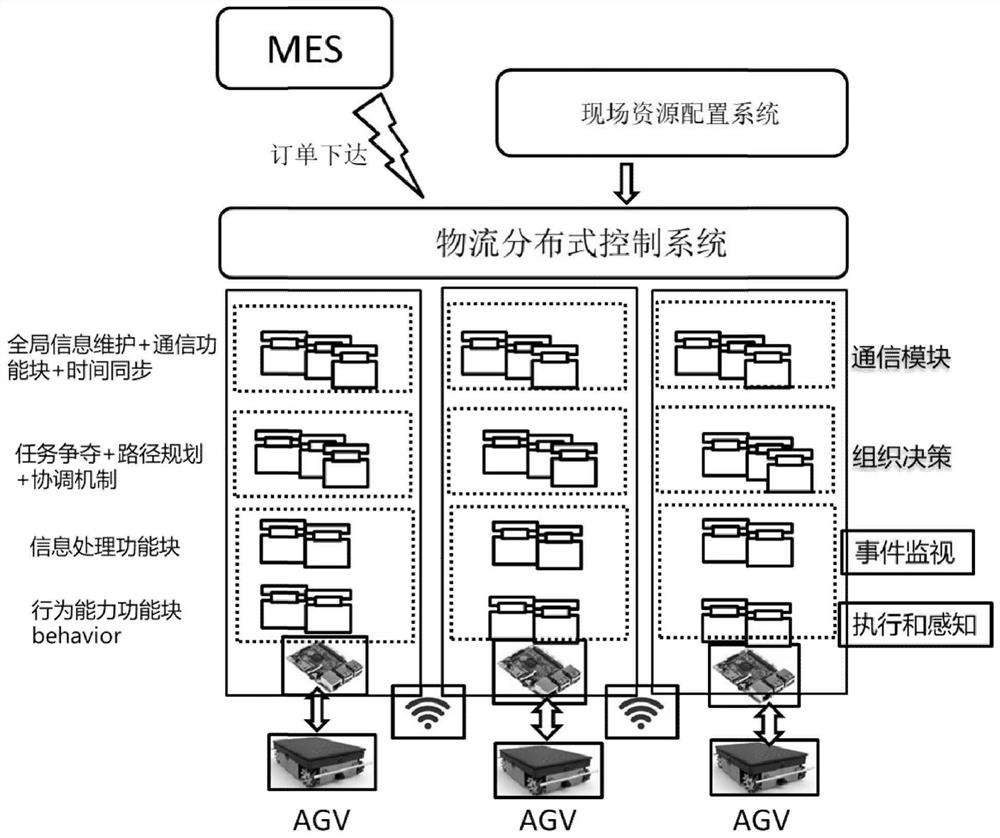

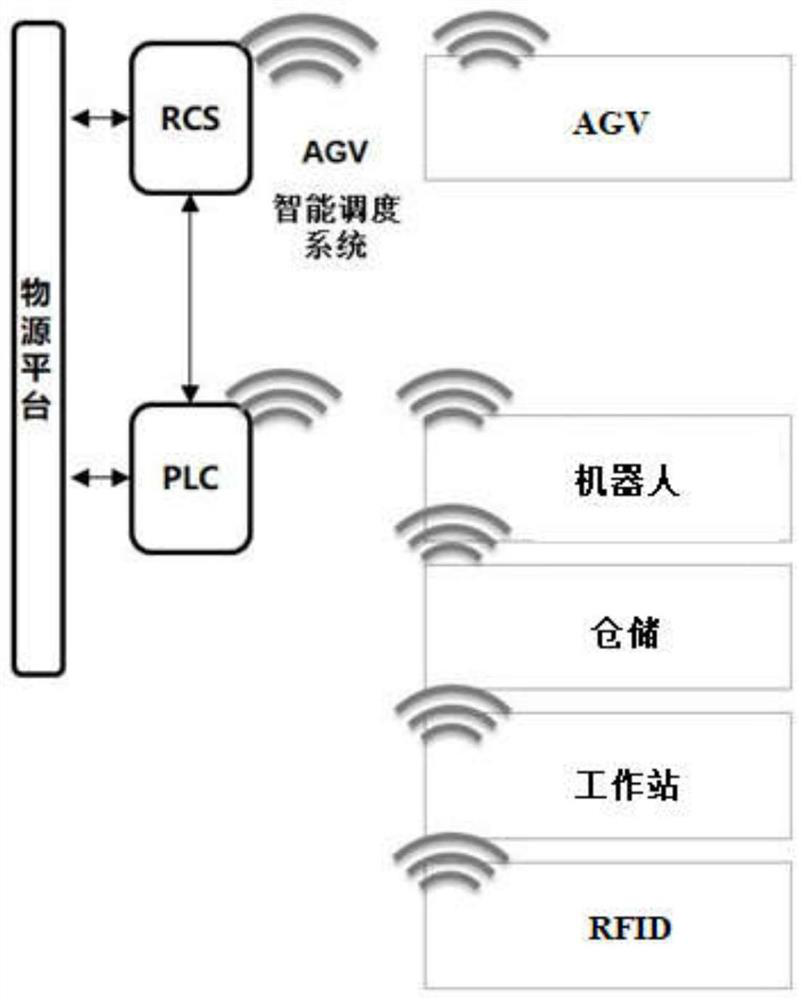

[0037] A flexible production control system based on multi-agents, including: an intelligent storage system, an intelligent manufacturing system, a communication system and a material source platform. The intelligent storage system includes but is not limited to storage shelves, storage trays, and RFID information readers; the intelligent manufacturing system includes but is not limited to intelligent assembly stations, intelligent processing stations and intelligent detection stations; the communication system includes But not limited to WIA-based wireless networking module; the material source platform includes but not limited to management and control integrated flexible control software and edge controller; the edge controller includes but not limited to AGV, human-machine collaborative robot and distributed AGV Control System.

[0038] The storage shelf includes a raw material storage area and a finished product storage area; the storage pallet is equipped with an RFID in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com