Structure-adjustable high-air-tightness stainless steel flange

A stainless steel, high airtight technology, applied in the direction of flange connection, connecting components, engine sealing, etc., can solve the problems of inability to improve the airtightness of assembly surfaces, inability to lock bolts laterally, inability to change structures, etc., to achieve improved Anti-loosening performance, improved external safety, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

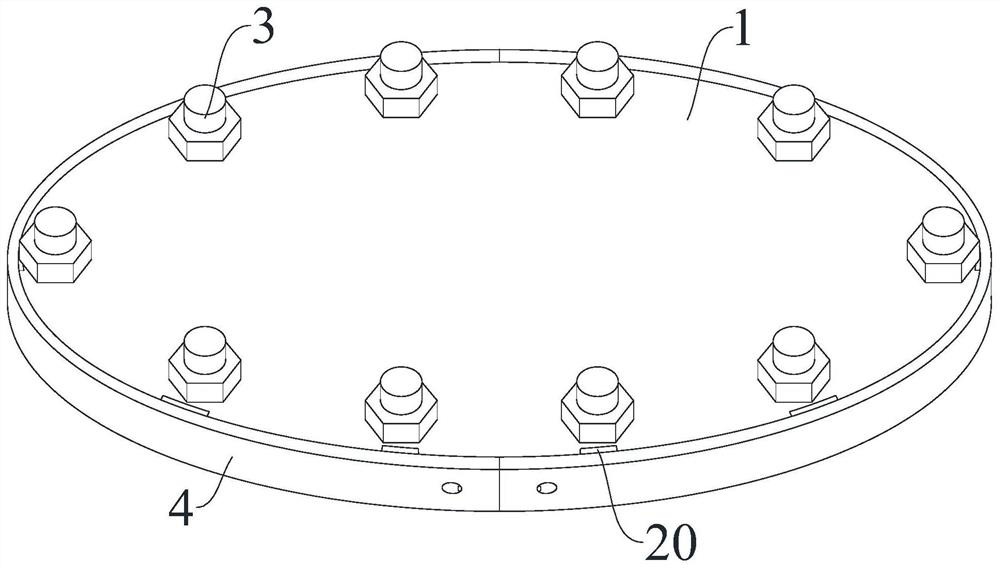

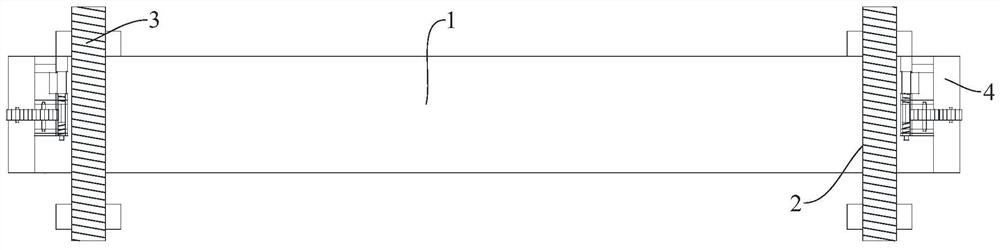

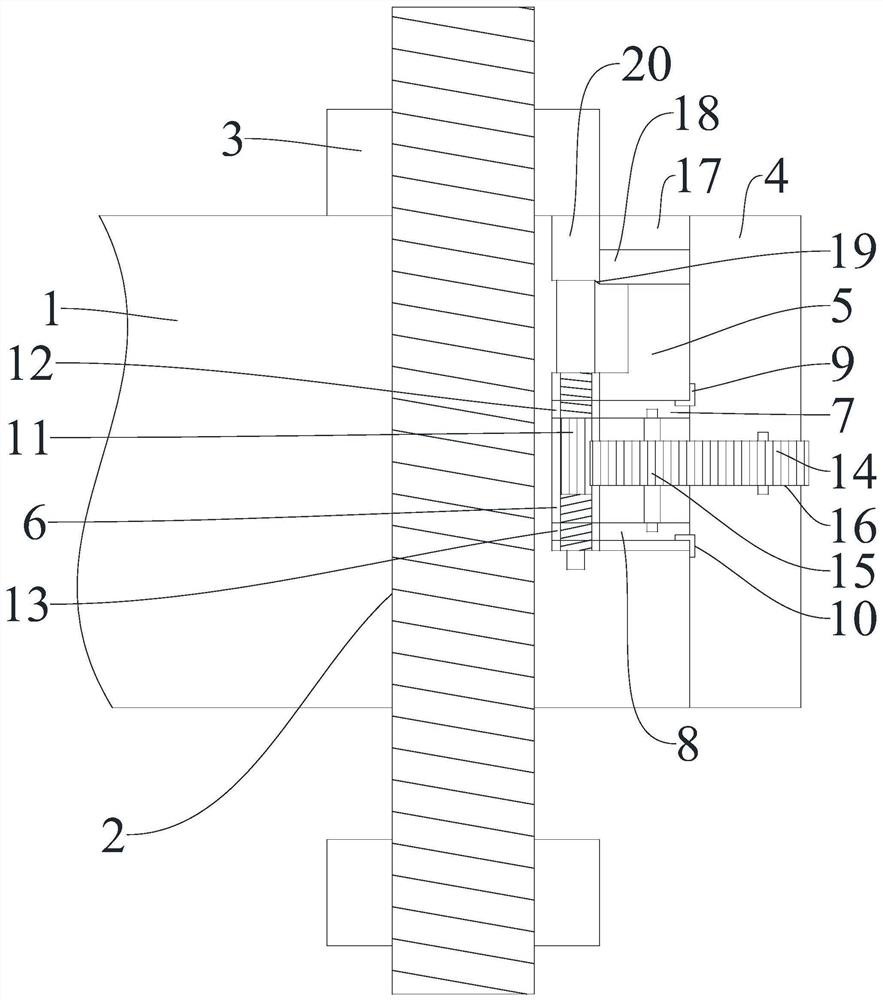

[0023] Embodiment: In the disassembly process, people rotate the internal thread loading and unloading sealing cover 20 to disassemble the internal thread loading and unloading sealing cover 20 from the inside of the internal thread top assembly groove 19, and then use the upper loading and unloading through hole to adjust the longitudinal adjustment mechanism, and then the annular side block The water cover 4 adopts a split design, which is fixedly assembled by bolts at the assembly ends on both sides, and separated and assembled by loosening the bolts. The annular side water shield 4 is lifted upwards to form a sealing groove with the upper surface of the flange body 1, and the liquid is injected inward to cooperate with the seal to prevent the entry of external air. If the internal air is discharged, it will be very convenient and quick to find.

[0024] Further, in order to improve the adjusted sealing performance, the inner arc surface of the annular side water shield 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com